Waste management or waste disposal includes the processes and actions required to manage waste from its inception to its final disposal. This includes the collection, transport, treatment, and disposal of waste, together with monitoring and regulation of the waste management process and waste-related laws, technologies, and economic mechanisms.

Domtar Corporation is a North American pulp and paper company that manufactures and markets wood fiber-based pulp and paper products. The company operates pulp mills and paper mills in Windsor, Quebec; Dryden, Ontario; Kamloops, British Columbia; Ashdown, Arkansas; Hawesville, Kentucky; Plymouth, North Carolina; Marlboro County, South Carolina; and Kingsport, Tennessee. While Domtar operated independently for several decades and was listed on the Toronto and New York stock exchanges, the company was acquired by Paper Excellence Group in November 2021 and has since operated as a subsidiary.

Eastman Chemical Company is an American company primarily involved in the chemical industry. Once a subsidiary of Kodak, today it is an independent global specialty materials company that produces a broad range of advanced materials, chemicals and fibers for everyday purposes. Founded in 1920 and based in Kingsport, Tennessee, the company operates 36 manufacturing sites worldwide and employs approximately 14,000 people.

The recycling of paper is the process by which waste paper is turned into new paper products. It has a number of important benefits: It saves waste paper from occupying homes of people and producing methane as it breaks down. Because paper fibre contains carbon, recycling keeps the carbon locked up for longer and out of the atmosphere. Around two-thirds of all paper products in the US are now recovered and recycled, although it does not all become new paper. After repeated processing the fibres become too short for the production of new paper, which is why virgin fibre is frequently added to the pulp recipe.

Industrial wastewater treatment describes the processes used for treating wastewater that is produced by industries as an undesirable by-product. After treatment, the treated industrial wastewater may be reused or released to a sanitary sewer or to a surface water in the environment. Some industrial facilities generate wastewater that can be treated in sewage treatment plants. Most industrial processes, such as petroleum refineries, chemical and petrochemical plants have their own specialized facilities to treat their wastewaters so that the pollutant concentrations in the treated wastewater comply with the regulations regarding disposal of wastewaters into sewers or into rivers, lakes or oceans. This applies to industries that generate wastewater with high concentrations of organic matter, toxic pollutants or nutrients such as ammonia. Some industries install a pre-treatment system to remove some pollutants, and then discharge the partially treated wastewater to the municipal sewer system.

Fisher Scientific International, Inc. was a laboratory supply and biotechnology company that provided products and services to the global scientific research and clinical laboratory markets until its merger with Thermo Electron in 2006, after which it became Thermo Fisher Scientific. The company offered products and services to over 350,000 customers located in approximately 150 countries including pharmaceutical and biotechnology companies, secondary and higher education institutions, hospitals and medical research institutions, and quality control, process control and research and development laboratories.

High-density polyethylene (HDPE) or polyethylene high-density (PEHD) is a thermoplastic polymer produced from the monomer ethylene. It is sometimes called "alkathene" or "polythene" when used for HDPE pipes. With a high strength-to-density ratio, HDPE is used in the production of plastic bottles, corrosion-resistant piping, geomembranes and plastic lumber. HDPE is commonly recycled, and has the number "2" as its resin identification code.

Plastic recycling is the processing of plastic waste into other products. Recycling can reduce dependence on landfill, conserve resources and protect the environment from plastic pollution and greenhouse gas emissions. Recycling rates lag behind those of other recoverable materials, such as aluminium, glass and paper. From the start of plastic production through to 2015, the world produced around 6.3 billion tonnes of plastic waste, only 9% of which has been recycled and only ~1% has been recycled more than once. Of the remaining waste, 12% was incinerated and 79% was either sent to landfills or lost to the environment as pollution.

A disposable is a product designed for a single use after which it is recycled or is disposed as solid waste. The term is also sometimes used for products that may last several months to distinguish from similar products that last indefinitely. The word "disposables" is not to be confused with the word "consumables", which is widely used in the mechanical world. For example, welders consider welding rods, tips, nozzles, gas, etc. to be "consumables", as they last only a certain amount of time before needing to be replaced. Consumables are needed for a process to take place, such as inks for printing and welding rods for welding, while disposable products are items that can be discarded after they become damaged or are no longer useful.

A mechanical biological treatment (MBT) system is a type of waste processing facility that combines a sorting facility with a form of biological treatment such as composting or anaerobic digestion. MBT plants are designed to process mixed household waste as well as commercial and industrial wastes.

Upcycling, also known as creative reuse, is the process of transforming by-products, waste materials, useless, or unwanted products into new materials or products perceived to be of greater quality, such as artistic value or environmental value.

Membrane bioreactors are combinations of membrane processes like microfiltration or ultrafiltration with a biological wastewater treatment process, the activated sludge process. These technologies are now widely used for municipal and industrial wastewater treatment. The two basic membrane bioreactor configurations are the submerged membrane bioreactor and the side stream membrane bioreactor. In the submerged configuration, the membrane is located inside the biological reactor and submerged in the wastewater, while in a side stream membrane bioreactor, the membrane is located outside the reactor as an additional step after biological treatment.

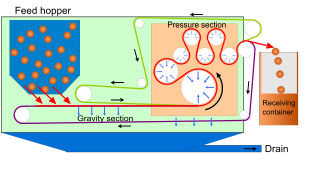

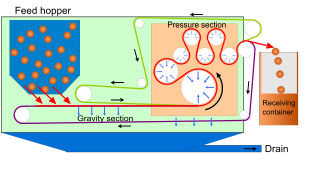

Deinking is the industrial process of removing printing ink from paperfibers of recycled paper to make deinked pulp.

The belt filter is an industrial machine, used for solid/liquid separation processes, particularly the dewatering of sludges in the chemical industry, mining and water treatment. Belt filter presses are also used in the production of apple juice, cider and winemaking. The process of filtration is primarily obtained by passing a pair of filtering cloths and belts through a system of rollers. The system takes a sludge or slurry as a feed, and separates it into a filtrate and a solid cake.

Plastics are a wide range of synthetic or semi-synthetic materials that use polymers as a main ingredient. Their plasticity makes it possible for plastics to be molded, extruded or pressed into solid objects of various shapes. This adaptability, plus a wide range of other properties, such as being lightweight, durable, flexible, and inexpensive to produce, has led to their widespread use. Plastics typically are made through human industrial systems. Most modern plastics are derived from fossil fuel-based chemicals like natural gas or petroleum; however, recent industrial methods use variants made from renewable materials, such as corn or cotton derivatives.

Founded in 1873, the Dieffenbacher Group, located in Eppingen in the administrative district of Heilbronn in Baden-Württemberg, is a family-run enterprise in the field of mechanical engineering, plant systems engineering, and construction. They develop and manufacture press systems and complete production systems for the wood composites, automobile, aerospace and recycling industries. In addition, the company develops power plants and process equipment for energy generation and waste heat recovery.

Products made from a variety of materials can be recycled using a number of processes.

Resource recovery is using wastes as an input material to create valuable products as new outputs. The aim is to reduce the amount of waste generated, thereby reducing the need for landfill space, and optimising the values created from waste. Resource recovery delays the need to use raw materials in the manufacturing process. Materials found in municipal solid waste, construction and demolition waste, commercial waste and industrial wastes can be used to recover resources for the manufacturing of new materials and products. Plastic, paper, aluminium, glass and metal are examples of where value can be found in waste.

VinyLoop is a proprietary physical plastic recycling process for polyvinyl chloride (PVC). It is based on dissolution in order to separate PVC from other materials or impurities.

Bellmer GmbH is a company founded in 1842 in Niefern-Öschelbronn, Germany by Carl Bellmer. It is still family-owned with over 600 employees globally. Bellmer operates 16 sites around the world but the products are manufactured in Germany and Finland.