The American National Standards Institute is a private nonprofit organization that oversees the development of voluntary consensus standards for products, services, processes, systems, and personnel in the United States. The organization also coordinates U.S. standards with international standards so that American products can be used worldwide.

Professional certification, trade certification, or professional designation, often called simply certification or qualification, is a designation earned by a person to assure qualification to perform a job or task. Not all certifications that use post-nominal letters are an acknowledgement of educational achievement, or an agency appointed to safeguard the public interest.

Safety is the state of being protected from harm or other danger. Safety can also refer to the control of recognized hazards in order to achieve an acceptable level of risk.

The UL enterprise is a global private safety company headquartered in Northbrook, Illinois, composed of three organizations, UL Research Institutes, UL Standards & Engagement and UL Solutions.

A standards organization, standards body, standards developing organization (SDO), or standards setting organization (SSO) is an organization whose primary function is developing, coordinating, promulgating, revising, amending, reissuing, interpreting, or otherwise contributing to the usefulness of technical standards to those who employ them. Such an organization works to create uniformity across producers, consumers, government agencies, and other relevant parties regarding terminology, product specifications, protocols, and more. Its goals could include ensuring that Company A's external hard drive works on Company B's computer, an individual's blood pressure measures the same with Company C's sphygmomanometer as it does with Company D's, or that all shirts that should not be ironed have the same icon on the label.

Occupational noise is the amount of acoustic energy received by an employee's auditory system when they are working in the industry. Occupational noise, or industrial noise, is often a term used in occupational safety and health, as sustained exposure can cause permanent hearing damage. Occupational noise is considered an occupational hazard traditionally linked to loud industries such as ship-building, mining, railroad work, welding, and construction, but can be present in any workplace where hazardous noise is present.

The Project Management Institute is a U.S.-based not-for-profit professional organization for project management.

The Sporting Arms and Ammunition Manufacturers' Institute is an association of American manufacturers of firearms, ammunition, and components. SAAMI is an accredited standards developer that publishes several American National Standards that provide safety, reliability, and interchangeability standards for commercial manufacturers of firearms, ammunition, and components. In addition, SAAMI publishes information on the safe and responsible transportation, storage, and use of those products.

Laser radiation safety is the safe design, use and implementation of lasers to minimize the risk of laser accidents, especially those involving eye injuries. Since even relatively small amounts of laser light can lead to permanent eye injuries, the sale and usage of lasers is typically subject to government regulations.

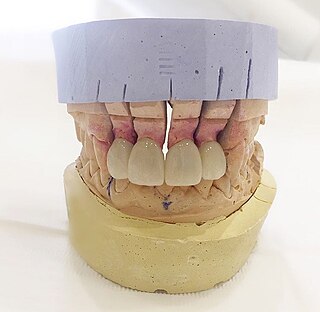

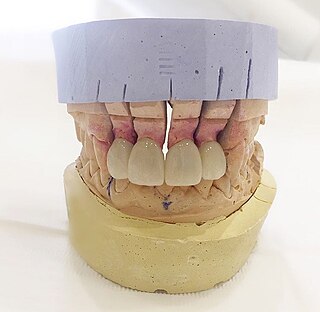

Dental laboratories manufacture or customize a variety of products to assist in the provision of oral health care by a licensed dentist. These products include crowns, bridges, dentures and other dental products. Dental lab technicians follow a prescription from a licensed dentist when manufacturing these items, which include prosthetic devices and therapeutic devices. The FDA regulates these products as medical devices and they are therefore subject to FDA's good manufacturing practice ("GMP") and quality system ("QS") requirements. In most cases, however, they are exempt from manufacturer registration requirements. Some of the most common restorations manufactured include crowns, bridges, dentures, and dental implants. Dental implants is one of the most advanced dental technologies in the field of dentistry.

The American Society of Safety Professionals (ASSP), formerly known as American Society of Safety Engineers (ASSE), is a global organization of occupational safety and health (OSH) professional members who manage, supervise, research and consult on work-related OSH concerns across all industries. Society members use risk-based approaches to prevent workplace fatalities, injuries and illnesses.

Association of Public-Safety Communications Officials (APCO) International was founded in 1935.

The American Trucking Associations (ATA), founded in 1933, is the largest national trade association for the trucking industry. ATA represents more than 37,000 members covering every type of motor carrier in the United States through a federation of other trucking groups, industry-related conferences, and its 50 affiliated state trucking associations. Former Governor of Kansas Bill Graves was replaced by Chris Spear as the ATA's president and CEO in July 2016.

An occupational safety management system (OSMS) is a management system designed to manage occupational safety and health risks in the workplace. If the system contains elements of management of longer-term health impacts and occupational disease, it may be referred to as a occupational safety and health management system (OSHMS) or occupational health and safety management system (OHSMS).

ANSI Z535 are American-developed standards designed to improve the identification of potential hazards to workers and/or property. The identifications are called Hazardous Communication (HazCom). ANSI Z535 sets the design and application standards for all HazCom used across North America and globally, in most industrialized nations. ANSI Z535 standards integrate with international ISO 3864 standards, ensuring the widest compliance, globally, with export/import laws. ANSI Z535 standardized HazCom may appear on workplace walls, industrial machines, at industrial access points, on electrical controls, inside product user guides, and on export documentation.

Accredited Crane Operator Certification OSHA regulation 29 CFR 1926 Subpart CC, released August 9, 2010, requires crane operators involved in construction to be certified by an accredited certification provider by November 10, 2014. An operator is defined as any person operating the equipment. To be accredited, certification providers must be accredited by a nationally recognized accrediting agency, defined as "an organization that, due to its independence and expertise, is widely recognized as competent to accredit testing organizations. Examples of such accrediting agencies include, but are not limited to, the National Commission for Certifying Agencies and the American National Standards Institute." This is the first time certification by an accredited certification provider has been required on a national level, although individual states and cities have required crane operator certification as far back as 2000. The new OSHA standards make the completion of this requirement an important topic of knowledge for the crane and lifting industry.

A cobot, or collaborative robot, also known as a companion robot, is a robot intended for direct human-robot interaction within a shared space, or where humans and robots are in close proximity. Cobot applications contrast with traditional industrial robot applications in which robots are isolated from human contact or the humans are protected by robotic tech vests. Cobot safety may rely on lightweight construction materials, rounded edges, and inherent limitation of speed and force, or on sensors and software that ensure safe behavior.

The National Operating Committee on Standards for Athletic Equipment is a nonprofit standards organization which develops standards for the manufacture of certain protective athletic equipment in the sports of baseball, football, hockey, lacrosse, and polo. NOCSAE conducts and funds scientific research and collects and analyzes data relating to standards development.

Occupational hearing loss (OHL) is hearing loss that occurs as a result of occupational hazards, such as excessive noise and ototoxic chemicals. Noise is a common workplace hazard, and recognized as the risk factor for noise-induced hearing loss and tinnitus but it is not the only risk factor that can result in a work-related hearing loss. Also, noise-induced hearing loss can result from exposures that are not restricted to the occupational setting.

Ursula Keller is a Swiss physicist. She has been a tenured physics professor at the ETH Zurich, Switzerland since 1993. A pioneer in ultrafast science and technology, she is known for inventing the semiconductor saturable absorber mirror (SESAM), enabling passive mode-locking of lasers and revolutionizing ultrafast laser applications in science and industry. Keller led the Swiss NCCR MUST program in ultrafast science (2010–2022), co-founded several companies, including Time-Bandwidth Products and K2 Photonics, and published a graduate textbook "Ultrafast Laser Physics" with Springer Verlag. She is highly cited and received many prestigious awards. From 2012-2016 she was the founding president of the Women Professors Forum at ETH Zurich.