Locomotive wheelslip is an event that affects railway motive power usually when starting from stationary, but can also affect an engine in motion.

Locomotive wheelslip is an event that affects railway motive power usually when starting from stationary, but can also affect an engine in motion.

The greatest effort is required from a locomotive when starting. At this time, if the engineer applies too much power to the wheels (i.e., for a steam locomotive, the engineer opens the regulator too far) the turning force applied to the wheel will greatly exceed the opposing friction force affected by the surface of the rail, and the wheel will turn without being able to move the train forward. If the engineer does not take quick corrective action (i.e. by closing the regulator) the locomotive can end up stationary with its wheels spinning: this can damage both the locomotive drive mechanism, through running too fast; and the rail surface, which, in extreme cases, can be left with a dip where the spin took place. Such a dip can be dangerous if not repaired.

Some locomotive types were more prone to this phenomenon than others. Also, the effect is much more likely to occur with a heavier train or where the rail surface is compromised, for example, during wet or icy weather, or when there is oil or leaves on the track.

The causes of locomotive wheelslip vary, but the predominant factor lies in the power-to-weight ratios. Ideally, locomotive designs will have roughly equal power-to-weight ratios that enable smooth acceleration from a 'cold start', or stopping position. However, if the power of a locomotive vastly exceeds its weight, then an imbalance ensues which causes the violent spinning of the wheels through loss of traction.

Other causes include the contact of oil with the flanges and rims of wheels, which reduces adhesion with the surface of the rails, and a general loss of traction on steep gradients when pulling heavy loads.

Most locomotives are fitted with sandboxes, so that sand or Sandite can be dropped on the rails to improve adhesion. Modern diesel locomotives and electric locomotives are fitted with electronic wheelspin detectors which automatically reduce the power supplied to the wheels if wheelspin is detected.

A bogie is a chassis or framework that carries a wheelset, attached to a vehicle—a modular subassembly of wheels and axles. Bogies take various forms in various modes of transport. A bogie may remain normally attached or be quickly detachable. It may include a suspension component within it, or be solid and in turn be suspended ; it may be mounted on a swivel, as traditionally on a railway carriage or locomotive, additionally jointed and sprung, or held in place by other means.

A rack railway is a steep grade railway with a toothed rack rail, usually between the running rails. The trains are fitted with one or more cog wheels or pinions that mesh with this rack rail. This allows the trains to operate on steep gradients of 100% or more, well above the 10% maximum for friction-based rail. The rack and pinion mechanism also provides more controlled braking and reduces the effects of snow or ice on the rails. Most rack railways are mountain railways, although a few are transit railways or tramways built to overcome a steep gradient in an urban environment. The first cog railway was the Middleton Railway between Middleton and Leeds in West Yorkshire, England, United Kingdom, where the first commercially successful steam locomotive, Salamanca, ran in 1812. This used a rack and pinion system designed and patented in 1811 by John Blenkinsop.

A steam locomotive is a locomotive that provides the force to move itself and other vehicles by means of the expansion of steam. It is fuelled by burning combustible material to heat water in the locomotive's boiler to the point where it becomes gaseous and its volume increases 1,700 times. Functionally, it is a steam engine on wheels.

In railway engineering, the term tractive effort describes the pulling or pushing capability of a locomotive. The published tractive force value for any vehicle may be theoretical—that is, calculated from known or implied mechanical properties—or obtained via testing under controlled conditions. The discussion herein covers the term's usage in mechanical applications in which the final stage of the power transmission system is one or more wheels in frictional contact with a railroad track.

Puffing Billy is the world's oldest surviving steam locomotive, constructed in 1813–1814 by colliery viewer William Hedley, enginewright Jonathan Forster and blacksmith Timothy Hackworth for Christopher Blackett, the owner of Wylam Colliery near Newcastle upon Tyne, in the United Kingdom. It was employed to haul coal chaldron wagons from the mine at Wylam to the docks at Lemington in Northumberland.

Understeer and oversteer are vehicle dynamics terms used to describe the sensitivity of the vehicle to changes in steering angle associated with changes in lateral acceleration. This sensitivity is defined for a level road for a given steady state operating condition by the Society of Automotive Engineers (SAE) in document J670 and by the International Organization for Standardization (ISO) in document 8855. Whether the vehicle is understeer or oversteer depends on the rate of change of the understeer angle. The Understeer Angle is the amount of additional steering that must be added in any given steady-state maneuver beyond the Ackermann steer angle. The Ackermann Steer Angle is the steer angle at which the vehicle would travel about a curve when there is no lateral acceleration required.

Main components found on a typical steam locomotive include:

In rail transport, a derailment is a type of train wreck that occurs when a rail vehicle such as a train comes off its rails. Although many derailments are minor, all result in temporary disruption of the proper operation of the railway system and they are a potentially serious hazard.

Under the Whyte notation for the classification of steam locomotives, 4-2-2 represents the wheel arrangement of four leading wheels on two axles, two powered driving wheels on one axle, and two trailing wheels on one axle.

Under the Whyte notation for the classification of steam locomotives, 4-2-4 represents the wheel arrangement of four leading wheels on two axles, two powered driving wheels on one axle, and four trailing wheels on two axles.

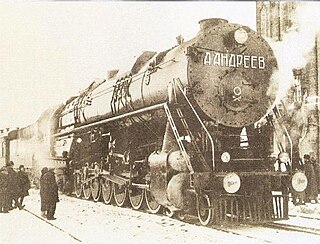

The AA20 was a one-off steam locomotive constructed by the Soviet Union.

An adhesion railway relies on adhesion traction to move the train, and is the most widespread and common type of railway in the world. Adhesion traction is the friction between the drive wheels and the steel rail. Since the vast majority of railways are adhesion railways, the term adhesion railway is used only when it is necessary to distinguish adhesion railways from railways moved by other means, such as by a stationary engine pulling on a cable attached to the cars or by a pinion meshing with a rack.

B-B and Bo-Bo are the Association of American Railroads (AAR) and British classifications of wheel arrangement for railway locomotives with four axles in two individual bogies. They are equivalent to the B′B′ and Bo′Bo′ classifications in the UIC system. The arrangement of two, two-axled, bogies is a common wheel arrangement for modern electric and diesel locomotives.

The history of rail transport in Great Britain to 1830 covers the period up to the opening of the Liverpool and Manchester Railway, the world's first intercity passenger railway operated solely by steam locomotives. The earliest form of railways, horse-drawn wagonways, originated in Germany in the 16th century. Soon wagonways were also built in Britain. However, the first use of steam locomotives was in Wales. The invention of wrought iron rails, together with Richard Trevithick's pioneering steam locomotive meant that Britain had the first modern railways in the world.

Slippery rail, or low railhead adhesion, is a condition of railways (railroads) where contamination of the railhead reduces the traction between the wheel and the rail. This can lead to wheelslip when the train is taking power, and wheelslide when the train is braking. One common cause of contamination is fallen leaves that adhere to the railhead of railway tracks. The condition results in significant reduction in friction between train wheels and rails, and in extreme cases can render the track temporarily unusable. In Britain, the situation is colloquially referred to as "leaves on the line".

A wheelspin occurs when the force delivered to the tire tread exceeds that of available tread-to-surface friction and one or more tires lose traction. This leads the wheels to "spin" and causes the driver to lose control over the tires that no longer have grip on the road surface. Wheelspin can also be done intentionally such as in drifting or doing a burnout.

Wheel slide protection and wheel slip protection are railway terms used to describe automatic systems used to detect and prevent wheel-slide during braking or wheel-slip during acceleration. This is analogous to ABS and traction control systems used on motor vehicles. It is particularly important in slippery rail conditions.

A dreadnaught wheel is a wheel with articulated rails attached at the rim to provide a firm footing for the wheel to roll over. These wheels have also been known as "endless railway wheels" when fitted to road locomotives, and were commonly fitted to steam traction engines. They are very similar to pedrail wheels, differing primarily in that their rails are not connected to the wheel directly, but articulated to each other.

A train wheel or rail wheel is a type of wheel specially designed for use on railway tracks. The wheel acts as a rolling component, typically press fitted onto an axle and mounted directly on a railway carriage or locomotive, or indirectly on a bogie, also called a truck. The powered wheels under the locomotive are called driving wheels. Wheels are initially cast or forged and then heat-treated to have a specific hardness. New wheels are machined using a lathe to a standardized shape, called a profile, before being installed onto an axle. All wheel profiles are regularly checked to ensure proper interaction between the wheel and the rail. Incorrectly profiled wheels and worn wheels can increase rolling resistance, reduce energy efficiency and may even cause a derailment. The International Union of Railways has defined a standard wheel diameter of 920 mm (36 in), although smaller sizes are used in some rapid transit railway systems and on ro-ro carriages.

Steam springs or steam suspension are a form of suspension used for some early steam locomotives designed and built by George Stephenson. They were only briefly used and may have been used for fewer than ten locomotives.