Zeolites are microporous, crystalline aluminosilicate materials commonly used as commercial adsorbents and catalysts. They mainly consist of silicon, aluminium, oxygen, and have the general formula Mn+

1/n(AlO

2)−

(SiO

2)

x・yH

2O where Mn+

1/n is either a metal ion or H+. These positive ions can be exchanged for others in a contacting electrolyte solution. H+

exchanged zeolites are particularly useful as solid acid catalysts.

Heterogeneous catalysis is catalysis where the phase of catalysts differs from that of the reactants or products. The process contrasts with homogeneous catalysis where the reactants, products and catalyst exist in the same phase. Phase distinguishes between not only solid, liquid, and gas components, but also immiscible mixtures, or anywhere an interface is present.

A molecular sieve is a material with pores of uniform size. These pore diameters are similar in size to small molecules, and thus large molecules cannot enter or be adsorbed, while smaller molecules can. As a mixture of molecules migrates through the stationary bed of porous, semi-solid substance referred to as a sieve, the components of the highest molecular weight leave the bed first, followed by successively smaller molecules. Some molecular sieves are used in size-exclusion chromatography, a separation technique that sorts molecules based on their size. Other molecular sieves are used as desiccants.

A mesoporous material is a nanoporous material containing pores with diameters between 2 and 50 nm, according to IUPAC nomenclature. For comparison, IUPAC defines microporous material as a material having pores smaller than 2 nm in diameter and macroporous material as a material having pores larger than 50 nm in diameter.

Cetrimonium bromide ([(C16H33)N(CH3)3]Br; cetyltrimethylammonium bromide; hexadecyltrimethylammonium bromide; CTAB) is a quaternary ammonium surfactant.

Nanoporous materials consist of a regular organic or inorganic bulk phase in which a porous structure is present. Nanoporous materials exhibit pore diameters that are most appropriately quantified using units of nanometers. The diameter of pores in nanoporous materials is thus typically 100 nanometers or smaller. Pores may be open or closed, and pore connectivity and void fraction vary considerably, as with other porous materials. Open pores are pores that connect to the surface of the material whereas closed pores are pockets of void space within a bulk material. Open pores are useful for molecular separation techniques, adsorption, and catalysis studies. Closed pores are mainly used in thermal insulators and for structural applications.

Mesoporous silicates are silicates with a special morphology.

Metal–organic frameworks (MOFs) are a class of compounds consisting of metal clusters coordinated to organic ligands to form one-, two-, or three-dimensional structures. The organic ligands included are sometimes referred to as "struts" or "linkers", one example being 1,4-benzenedicarboxylic acid (BDC).

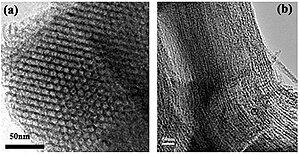

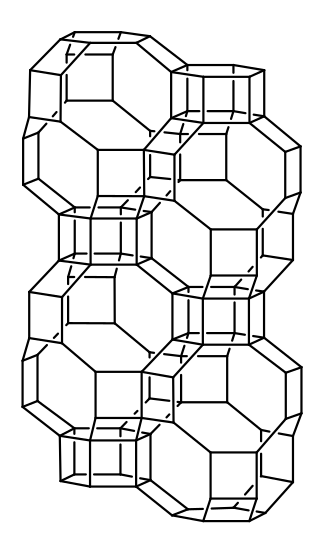

Mesoporous silica is a form of silica that is characterised by its mesoporous structure, that is, having pores that range from 2 nm to 50 nm in diameter. According to IUPAC's terminology, mesoporosity sits between microporous (<2 nm) and macroporous (>50 nm). Mesoporous silica is a relatively recent development in nanotechnology. The most common types of mesoporous nanoparticles are MCM-41 and SBA-15. Research continues on the particles, which have applications in catalysis, drug delivery and imaging. Mesoporous ordered silica films have been also obtained with different pore topologies.

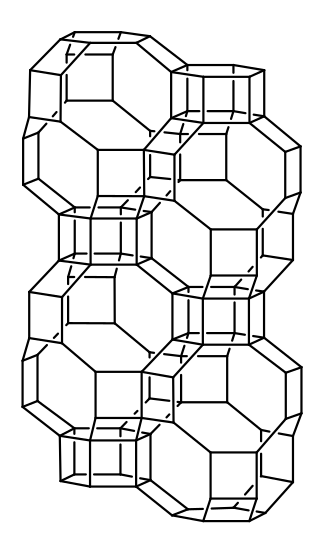

Mobil Composition of Matter (MCM) is the initial name given for a series of mesoporous materials that were first synthesized by Mobil's researchers in 1992. MCM-41 and MCM-48 are two of the most popular mesoporous molecular sieves that are keenly studied by researchers.

ZSM-5, Zeolite Socony Mobil–5 (framework type MFI from ZSM-5 (five)), is an aluminosilicate zeolite belonging to the pentasil family of zeolites. Its chemical formula is NanAlnSi96–nO192·16H2O (0<n<27). Patented by Mobil Oil Company in 1975, it is widely used in the petroleum industry as a heterogeneous catalyst for hydrocarbon isomerization reactions.

SSZ-13 (framework type code CHA) is a high-silica aluminosilicate zeolite possessing 0.38 × 0.38 nm micropores. It belongs to the ABC-6 family of zeolites as well as offretite, cancrinite, erionite and other related small-pore zeolites. The framework topology is the same as that of chabazite but SSZ-13 has a high silica composition with Si/Al > 5, which leads to low cation exchange capacity. The typical chemical formula of the unit cell can be described as QxNayAl2.4Si33.6O72•zH2O (1.4 < x <27)(0.7 < y < 4.3)(1 < z <7), where Q is N,N,N-1-trimethyladamantammonium. The material was patented by Chevron research Company in 1985, and could potentially be used as a solid catalyst for the methanol-to-olefins (MTO) process and the selective catalytic reduction (SCR) of NOx.

In chemistry, germanate is a compound containing an oxyanion of germanium. In the naming of inorganic compounds it is a suffix that indicates a polyatomic anion with a central germanium atom, for example potassium hexafluorogermanate, K2GeF6.

The Stöber process is a chemical process used to prepare silica particles of controllable and uniform size for applications in materials science. It was pioneering when it was reported by Werner Stöber and his team in 1968, and remains today the most widely used wet chemistry synthetic approach to silica nanoparticles. It is an example of a sol-gel process wherein a molecular precursor is first reacted with water in an alcoholic solution, the resulting molecules then joining together to build larger structures. The reaction produces silica particles with diameters ranging from 50 to 2000 nm, depending on conditions. The process has been actively researched since its discovery, including efforts to understand its kinetics and mechanism – a particle aggregation model was found to be a better fit for the experimental data than the initially hypothesized LaMer model. The newly acquired understanding has enabled researchers to exert a high degree of control over particle size and distribution and to fine-tune the physical properties of the resulting material in order to suit intended applications.

Mesoporous organosilica are a type of silica containing organic groups that give rise to mesoporosity. They exhibit pore size ranging from 2 nm - 50 nm, depending on the organic substituents. In contrast, zeolites exhibit pore sizes less than a nanometer. PMOs have potential applications as catalysts, adsorbents, trapping agents, drug delivery agents, stationary phases in chromatography and chemical sensors.

Ryoo Ryong FRSC is a distinguished professor of chemistry at KAIST in Daejeon, South Korea. He was the head of the Center for Nanomaterials and Chemical Reactions, an Extramural Research Center of the Institute for Basic Science. Ryoo has won a variety of awards, including the Top Scientist Award given by the South Korean government in 2005. He obtained the KOSEF Science and Technology Award in 2001 for his work on the synthesis and crystal structure of mesoporous silica.

Charles T. Kresge is a chemist and retired Chief Technology Officer (CTO) of Saudi Aramco. He was R&D Vice President at the Dow Chemical Company. His area of expertise is inorganic synthesis, and his primary field of research is in the area of crystalline aluminosilicate materials, particularly for the discovery of mesoporous molecular sieves.

Ionosilicas are defined as organosilicas containing chemically bound ionic groups. They represent a class of mesoporous organosilicas.

Michael Tsapatsis is an American chemical engineer and materials scientist. Tsapatsis is the 36th Bloomberg Distinguished Professor at Johns Hopkins University in the Department of Chemical and Biomolecular Engineering. Prior to this position he was the Amundson Chair (2008–present), professor (2003-present), and McKnight Presidential Endowed Chair (2017–present) in the department of chemical engineering and Materials Science at the University of Minnesota. Prior to his appointment at the University of Minnesota, Tsapatsis was an associate professor at the University of Massachusetts Amherst.

Steven L. Suib is an American inorganic chemist, academic and researcher. He is a Board of Trustees Distinguished Professor of Chemistry at University of Connecticut. He is a director of the Institute of Materials Science and of the Center for Advanced Microscopy and Materials Analysis.