History

MPDS’ history [2] is tied in with the Computer-Aided Design Centre (or CAD Centre) which was created in Cambridge in 1967 by the UK Government to carry out CAD research.

Famous British computer scientist Dr. Dick Newell worked there on a file-based macro language-driven 3D plant design system called PDMS (Plant Design Management System). With colleague Tom Sancha, he left the CAD Centre in 1977 to form a company called Cambridge Interactive Systems or CIS, and primarily concentrated on 2D CAD. CIS had developed an electrical cabling solution initially called CABLOS, which Dowty Engineering first purchased in about 1979. Another early adopter was BMW, which used the system for car wiring diagrams. CABLOS soon became known and sold as the MEDUSA drafting system under CIS. The proprietary programming language with which MEDUSA version 1 was developed was known as baCIS 1. Around this time, the company also began developing its own 3D modeling kernel for MEDUSA.

Around 1980, CIS partnered with Prime Computer, a U.S.-based computer hardware provider. Prime had an option on the MEDUSA source code should CIS ever fail. In 1983 the U.S. CAD company ComputerVision purchased CIS.

ComputerVision/CIS started developing the MEDUSA Plant Design System (MPDS), the first plant design software based on a relational database. Developers knew from their prior experience with a file-based macro-language driven system that the next generation plant design system had to be built on a relational database and with a much more powerful programming language to handle large data volumes, complexity and relationships. Whereas mechanical CAD engineers were developing machinery with a few hundred or maybe a thousand components, plant design engineers typically needed to deal with hundreds of thousands of components. To facilitate this work, the baCIS 2 interpretive language and the MDB relational database were developed for MPDS. Existing MEDUSA technology was used to create the 2D and 3D geometric data required for plant layouts. The creation of this data-centric concept separated the 3D visualization of a plant from the underlying database and allowed engineers to plan and design installations with very large volumes of data, and produce all the required 2D drawings from 3D plant designs. [3]

The first MPDS sales date to around 1988 to NEI Parsons (Northern Engineering Industries later became part of the Rolls-Royce Industrial Power Group). Courtaulds Engineering, which had been using MEDUSA since 1983, was also an early MPDS adopter.

In the same year Prime Computer merged with ComputerVision and adopted the name ComputerVision to concentrate on software, due to declining hardware sales. MEDUSA continued to be developed throughout the 1990s in Cambridge, UK at ComputerVision's R&D Centre at Harston Mill.

In 1993, the next generation of MEDUSA and MPDS was released. What would have been version 13 was released as MEDUSA NG and MPDS NG. They signified the shift from tablet-driven menus to a graphical user interface, although tablets could still be used on that release.

In 1994 ComputerVision closed its R&D facility in Cambridge, moving to Boston, Massachusetts. As a result, five former ComputerVision staff members and MEDUSA experts formed the company Quintic Ltd in Cambridge, which continued to provide MEDUSA and MPDS development and consultancy services to ComputerVision and the MEDUSA customer base. Work included the porting of MEDUSA NG to Microsoft Windows.

Note: The above doesn't quite work. According to Companies House, Quintic Ltd was not actually formed until 27th February 2013, 19 years after the Cambridge R&D facility closed.

In 1998 the American CAD company Parametric Technology Corporation (PTC) acquired ComputerVision. The development partnership between Quintic and ComputerVision transferred to PTC.

The largest MEDUSA user base was in the heavily, manufacturing-driven, economy of Germany. CAD Schroer, a company founded in 1986 by Michael Schroer as a provider of CAD-based engineering services, became a MEDUSA vendor in 1988, having used the software extensively on client projects. The company, which also provided add-on modules and customizations, had established a development relationship first with ComputerVision, then with PTC.

In 2001, CAD Schroer acquired all rights to MEDUSA and MPDS from PTC. The development partnership between Quintic and CAD Schroer strengthened, as the two companies worked to create a Fourth Generation release of MEDUSA and MPDS. This included a complete overhaul of the functionality; the development of a graphical user interface (GUI) based on the Qt (framework) technology, the development of data exchange mechanisms and interfaces with third party systems, and the porting to the Linux open-source operating system.

In 2005, CAD Schroer acquired its development partner Quintic Ltd, gaining CAD development expertise that dates back to the days of CIS and Prime. CAD Schroer UK remains a software development center in Cambridge, whose staff continue to develop and support MEDUSA4 and MPDS4 in partnership with CAD development experts at CAD Schroer GmbH in Moers, Germany.

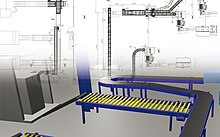

In 2006, CAD Schroer released the Fourth Generation of the MPDS plant design system, MPDS4. Since then the company has continued to develop and extend the functionality of the product suite, including the development of a factory layout module for designing 3D factories based on 2D drawings.