In meteorology, an anemometer is a device that measures wind speed and direction. It is a common instrument used in weather stations. The earliest known description of an anemometer was by Italian architect and author Leon Battista Alberti (1404–1472) in 1450.

In physics, the Coriolis force is an inertial force that acts on objects in motion within a frame of reference that rotates with respect to an inertial frame. In a reference frame with clockwise rotation, the force acts to the left of the motion of the object. In one with anticlockwise rotation, the force acts to the right. Deflection of an object due to the Coriolis force is called the Coriolis effect. Though recognized previously by others, the mathematical expression for the Coriolis force appeared in an 1835 paper by French scientist Gaspard-Gustave de Coriolis, in connection with the theory of water wheels. Early in the 20th century, the term Coriolis force began to be used in connection with meteorology.

Pressure measurement is the measurement of an applied force by a fluid on a surface. Pressure is typically measured in units of force per unit of surface area. Many techniques have been developed for the measurement of pressure and vacuum. Instruments used to measure and display pressure mechanically are called pressure gauges,vacuum gauges or compound gauges. The widely used Bourdon gauge is a mechanical device, which both measures and indicates and is probably the best known type of gauge.

A viscometer is an instrument used to measure the viscosity of a fluid. For liquids with viscosities which vary with flow conditions, an instrument called a rheometer is used. Thus, a rheometer can be considered as a special type of viscometer. Viscometers can measure only constant viscosity, that is, viscosity that does not change with flow conditions.

In fluid dynamics, a vortex is a region in a fluid in which the flow revolves around an axis line, which may be straight or curved. Vortices form in stirred fluids, and may be observed in smoke rings, whirlpools in the wake of a boat, and the winds surrounding a tropical cyclone, tornado or dust devil.

Flow measurement is the quantification of bulk fluid movement. Flow can be measured using devices called flowmeters in various ways. The common types of flowmeters with industrial applications are listed below:

Time of flight (ToF) is the measurement of the time taken by an object, particle or wave to travel a distance through a medium. This information can then be used to measure velocity or path length, or as a way to learn about the particle or medium's properties. The traveling object may be detected directly or indirectly. Time of flight technology has found valuable applications in the monitoring and characterization of material and biomaterials, hydrogels included.

Rotational spectroscopy is concerned with the measurement of the energies of transitions between quantized rotational states of molecules in the gas phase. The rotational spectrum of polar molecules can be measured in absorption or emission by microwave spectroscopy or by far infrared spectroscopy. The rotational spectra of non-polar molecules cannot be observed by those methods, but can be observed and measured by Raman spectroscopy. Rotational spectroscopy is sometimes referred to as pure rotational spectroscopy to distinguish it from rotational-vibrational spectroscopy where changes in rotational energy occur together with changes in vibrational energy, and also from ro-vibronic spectroscopy where rotational, vibrational and electronic energy changes occur simultaneously.

A torsion spring is a spring that works by twisting its end along its axis; that is, a flexible elastic object that stores mechanical energy when it is twisted. When it is twisted, it exerts a torque in the opposite direction, proportional to the amount (angle) it is twisted. There are various types:

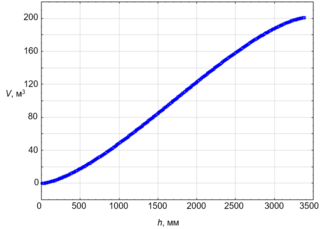

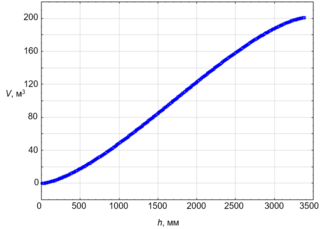

A gas meter is a specialized flow meter, used to measure the volume of fuel gases such as natural gas and liquefied petroleum gas. Gas meters are used at residential, commercial, and industrial buildings that consume fuel gas supplied by a gas utility. Gases are more difficult to measure than liquids, because measured volumes are highly affected by temperature and pressure. Gas meters measure a defined volume, regardless of the pressurized quantity or quality of the gas flowing through the meter. Temperature, pressure, and heating value compensation must be made to measure actual amount and value of gas moving through a meter.

Rotation around a fixed axis or axial rotation is a special case of rotational motion around an axis of rotation fixed, stationary, or static in three-dimensional space. This type of motion excludes the possibility of the instantaneous axis of rotation changing its orientation and cannot describe such phenomena as wobbling or precession. According to Euler's rotation theorem, simultaneous rotation along a number of stationary axes at the same time is impossible; if two rotations are forced at the same time, a new axis of rotation will result.

In physics, rotational–vibrational coupling occurs when the rotation frequency of a system is close to or identical to a natural frequency of internal vibration. The animation on the right shows ideal motion, with the force exerted by the spring and the distance from the center of rotation increasing together linearly with no friction.

Inertial waves, also known as inertial oscillations, are a type of mechanical wave possible in rotating fluids. Unlike surface gravity waves commonly seen at the beach or in the bathtub, inertial waves flow through the interior of the fluid, not at the surface. Like any other kind of wave, an inertial wave is caused by a restoring force and characterized by its wavelength and frequency. Because the restoring force for inertial waves is the Coriolis force, their wavelengths and frequencies are related in a peculiar way. Inertial waves are transverse. Most commonly they are observed in atmospheres, oceans, lakes, and laboratory experiments. Rossby waves, geostrophic currents, and geostrophic winds are examples of inertial waves. Inertial waves are also likely to exist in the molten core of the rotating Earth.

The magnetorotational instability (MRI) is a fluid instability that causes an accretion disk orbiting a massive central object to become turbulent. It arises when the angular velocity of a conducting fluid in a magnetic field decreases as the distance from the rotation center increases. It is also known as the Velikhov–Chandrasekhar instability or Balbus–Hawley instability in the literature, not to be confused with the electrothermal Velikhov instability. The MRI is of particular relevance in astrophysics where it is an important part of the dynamics in accretion disks.

Custody Transfer in the oil and gas industry refers to the transactions involving transporting physical substance from one operator to another. This includes the transferring of raw and refined petroleum between tanks and railway tank cars; onto ships, and other transactions. Custody transfer in fluid measurement is defined as a metering point (location) where the fluid is being measured for sale from one party to another. During custody transfer, accuracy is of great importance to both the company delivering the material and the eventual recipient, when transferring a material.

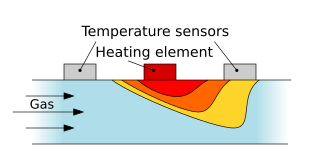

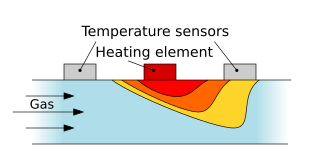

Thermal mass flow meters, also known as thermal dispersion or immersible mass flow meters, comprise a family of instruments for the measurement of the total mass flow rate of a fluid, primarily gases, flowing through closed conduits. A second type is the capillary-tube type of thermal mass flow meter. Many mass flow controllers (MFC) which combine a mass flow meter, electronics and a valve are based on this design. Furthermore, a thermal mass flow meter can be built by measuring temperature differential across a silicon-based MEMS chip.

Flow conditioning ensures that the "real world" environment closely resembles the "laboratory" environment for proper performance of inferential flowmeters like orifice, turbine, coriolis, ultrasonic etc.

This glossary of physics is a list of definitions of terms and concepts relevant to physics, its sub-disciplines, and related fields, including mechanics, materials science, nuclear physics, particle physics, and thermodynamics. For more inclusive glossaries concerning related fields of science and technology, see Glossary of chemistry terms, Glossary of astronomy, Glossary of areas of mathematics, and Glossary of engineering.

A density meter (densimeter) is a device which measures the density of an object or material. Density is usually abbreviated as either or . Typically, density either has the units of or . The most basic principle of how density is calculated is by the formula: