Thomas Newcomen was an English inventor who created the atmospheric engine, the first practical fuel-burning engine in 1712. He was an ironmonger by trade and a Baptist lay preacher by calling.

Thomas Savery was an English inventor and engineer, born at Shilstone, a manor house near Modbury, Devon, England. He invented the first commercially used steam-powered device, a steam pump which is often referred to as an "engine", although it is not technically an engine. Savery's steam pump was a revolutionary method of pumping water, which solved the problem of mine drainage and made widespread public water supply practicable.

The atmospheric engine was invented by Thomas Newcomen in 1712, and is often referred to simply as a Newcomen engine. The engine was operated by condensing steam drawn into the cylinder, thereby creating a partial vacuum which allowed the atmospheric pressure to push the piston into the cylinder. It was the first practical device to harness steam to produce mechanical work. Newcomen engines were used throughout Britain and Europe, principally to pump water out of mines. Hundreds were constructed throughout the 18th century.

Open-pit mining, also known as open-cast or open-cut mining and in larger contexts mega-mining, is a surface mining technique of extracting rock or minerals from the earth from an open-air pit, sometimes known as a borrow.

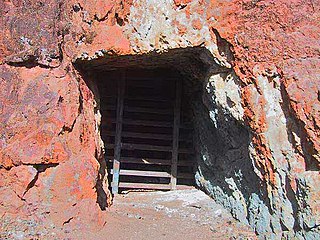

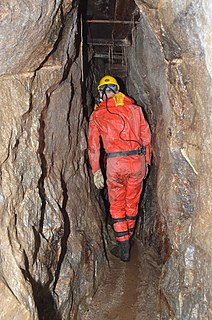

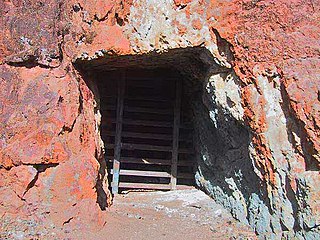

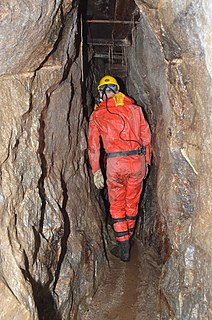

An adit is an entrance to an underground mine which is horizontal or nearly horizontal, by which the mine can be entered, drained of water, ventilated, and minerals extracted at the lowest convenient level. Adits are also used to explore for mineral veins.

In mining, tailings are the materials left over after the process of separating the valuable fraction from the uneconomic fraction (gangue) of an ore. Tailings are distinct from overburden, which is the waste rock or other material that overlies an ore or mineral body and is displaced during mining without being processed.

Surface mining, including strip mining, open-pit mining and mountaintop removal mining, is a broad category of mining in which soil and rock overlying the mineral deposit are removed, in contrast to underground mining, in which the overlying rock is left in place, and the mineral is removed through shafts or tunnels.

A sough is an underground channel for draining water out of a mine. Ideally the bottom of the mine would be higher than the outlet, but where the mine sump is lower, water must be pumped up to the sough.

The Minera Lead Mines were a mining operation and are now a country park and tourist centre in the village of Minera near Wrexham, in Wrexham County Borough, Wales.

Prestongrange Museum is an industrial heritage museum at Prestongrange between Musselburgh and Prestonpans on the B1348 on the East Lothian coast, Scotland. Founded as the original site of the National Mining Museum, its operation reverted to East Lothian Council Museum Service in 1992.

The following outline is provided as an overview of and topical guide to mining:

Chatterley Whitfield Colliery is a disused coal mine on the outskirts of Chell, Staffordshire in Stoke on Trent, England. It was the largest mine working the North Staffordshire Coalfield and was the first colliery in the UK to produce one million tons of saleable coal in a year.

The Hoffman tunnel, or Hoffman drainage tunnel, was constructed to drain water from coal mines northwest of Clarysville in Allegany County, Maryland. The two-mile-long tunnel drains into the Braddock Run tributary of Wills Creek.

Dewatering is the removal of water from solid material or soil by wet classification, centrifugation, filtration, or similar solid-liquid separation processes, such as removal of residual liquid from a filter cake by a filter press as part of various industrial processes.

Environmental effects of mining can occur at local, regional, and global scales through direct and indirect mining practices. The effects can result in erosion, sinkholes, loss of biodiversity, or the contamination of soil, groundwater, and surface water by the chemicals emitted from mining processes. These processes also affect the atmosphere from the emissions of carbon which have an effect on the quality of human health and biodiversity. Some mining methods may have such significant environmental and public health effects that mining companies in some countries are required to follow strict environmental and rehabilitation codes to ensure that the mined area returns to its original state.

The Ingleton Coalfield is in North Yorkshire, close to its border with Lancashire in north-west England. Isolated from other coal-producing areas, it is one of the smallest coalfields in Great Britain.

Pit water, mine water or mining water is water that collects in a mine and which has to be brought to the surface by water management methods in order to enable the mine to continue working.

A flooded mine is one of the direct results of a mine's closure procedure. When a mine stops to operate, its maintenance systems also stop, in which the dewatering systems are included. Without these systems the mine will get flooded by water that naturally sits in rock formations and in the ground.

Hapton Valley Colliery was a coal mine on the edge of Hapton near Burnley in Lancashire, England. Its first shafts were sunk in the early 1850s and it had a life of almost 130 years, surviving to be the last deep mine operating on the Burnley Coalfield.

The Wanlockhead beam engine is located close to the Wanlock Water below Church Street on the B797 in the village of Wanlockhead, Parish of Sanquhar, Dumfries and Galloway, Scotland. The site is in the Lowther Hills above the Mennock Pass, a mile south of Leadhills in the Southern Uplands. This is the only remaining original water powered beam engine in the United Kingdom and still stands at its original location. It ceased working circa 1910 after installation circa 1870.