| Part of a series of articles on |

| Nanomaterials |

|---|

|

| Carbon nanotubes |

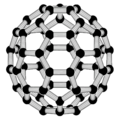

| Fullerenes |

| Other nanoparticles |

| Nanostructured materials |

Nanoporous materials consist of a regular organic or inorganic bulk phase in which a porous structure is present. Nanoporous materials exhibit pore diameters that are most appropriately quantified using units of nanometers. The diameter of pores in nanoporous materials is thus typically 100 nanometers or smaller. Nanoporous materials include subsets of mesoporous (with typical pores having sizes between 2 and 50 nanometers) and microporous materials (typical pores with diameters <2nm). [1] Pores may be open or closed, and pore connectivity and void fraction vary considerably, as with other porous materials. Open pores are pores that connect to the surface of the material whereas closed pores are pockets of void space within a bulk material. Open pores are useful for molecular separation techniques, adsorption, and catalysis studies. Closed pores are mainly used in thermal insulators and for structural applications. [2]

Contents

- Classifications

- Classification By Size

- Classification By Network Materials

- Applications

- Gas Storage/Sensing

- Biological applications

- References

Most nanoporous materials can be classified as bulk materials or membranes. Activated carbon and zeolites are two examples of bulk nanoporous materials, while cell membranes can be thought of as nanoporous membranes. [3] A porous medium or a porous material is a material containing pores (voids). The skeletal portion of the material is often called the "matrix" or "frame". The pores are typically filled with a fluid (liquid or gas).

- There are many natural nanoporous materials, but artificial materials can also be manufactured. One method of doing so is to combine polymers with different melting points, so that upon heating one polymer degrades. A nanoporous material with consistently sized pores has the property of letting only certain substances pass through, while blocking others. [3]