Sintering or frittage is the process of compacting and forming a solid mass of material by pressure or heat without melting it to the point of liquefaction.

Flow cytometry (FC) is a technique used to detect and measure physical and chemical characteristics of a population of cells or particles.

The angle of repose, or critical angle of repose, of a granular material is the steepest angle of descent or dip relative to the horizontal plane to which the material can be piled without slumping. At this angle, the material on the slope face is on the verge of sliding. The angle of repose can range from 0° to 90°. The morphology of the material affects the angle of repose; smooth, rounded sand grains cannot be piled as steeply as can rough, interlocking sands. The angle of repose can also be affected by additions of solvents. If a small amount of water is able to bridge the gaps between particles, electrostatic attraction of the water to mineral surfaces will increase the angle of repose, and related quantities such as the soil strength.

Granularity, the condition of existing in granules or grains, refers to the extent to which a material or system is composed of distinguishable pieces. It can either refer to the extent to which a larger entity is subdivided, or the extent to which groups of smaller indistinguishable entities have joined together to become larger distinguishable entities.

Particle image velocimetry (PIV) is an optical method of flow visualization used in education and research. It is used to obtain instantaneous velocity measurements and related properties in fluids. The fluid is seeded with tracer particles which, for sufficiently small particles, are assumed to faithfully follow the flow dynamics. The fluid with entrained particles is illuminated so that particles are visible. The motion of the seeding particles is used to calculate speed and direction of the flow being studied.

A mill is a device, often a structure, machine or kitchen appliance, that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many processes. There are many different types of mills and many types of materials processed in them. Historically mills were powered by hand or by animals, working animal, wind (windmill) or water (watermill). In modern era, they are usually powered by electricity.

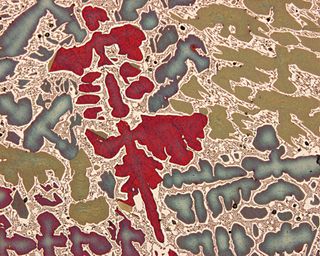

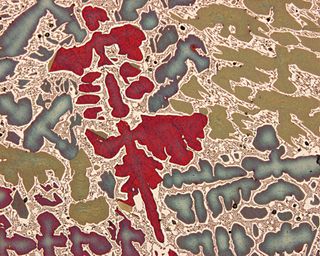

Microstructure is the very small scale structure of a material, defined as the structure of a prepared surface of material as revealed by an optical microscope above 25× magnification. The microstructure of a material can strongly influence physical properties such as strength, toughness, ductility, hardness, corrosion resistance, high/low temperature behaviour or wear resistance. These properties in turn govern the application of these materials in industrial practice.

Metallography is the study of the physical structure and components of metals, by using microscopy.

A granule is a large particle or grain. It can refer to:

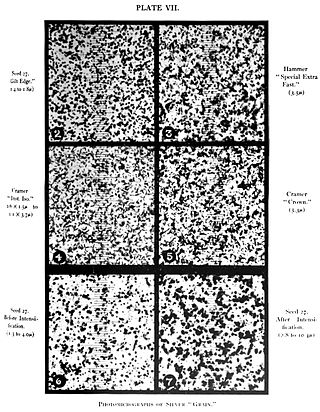

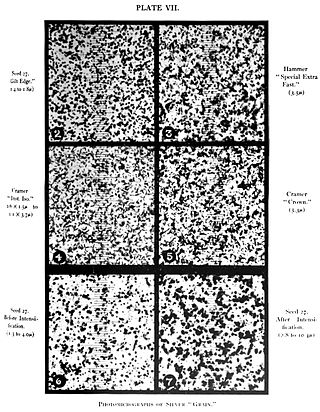

Film grain or granularity is the random optical texture of processed photographic film due to the presence of small particles of a metallic silver, or dye clouds, developed from silver halide that have received enough photons. While film grain is a function of such particles it is not the same thing as such. It is an optical effect, the magnitude of which depends on both the film stock and the definition at which it is observed. It can be objectionably noticeable in an over-enlarged film photograph.

A sieve analysis is a practice or procedure used in civil engineering and chemical engineering to assess the particle size distribution of a granular material by allowing the material to pass through a series of sieves of progressively smaller mesh size and weighing the amount of material that is stopped by each sieve as a fraction of the whole mass.

In granulometry, the particle-size distribution (PSD) of a powder, or granular material, or particles dispersed in fluid, is a list of values or a mathematical function that defines the relative amount, typically by mass, of particles present according to size. Significant energy is usually required to disintegrate soil, etc. particles into the PSD that is then called a grain size distribution.

Particle size is a notion introduced for comparing dimensions of solid particles, liquid particles (droplets), or gaseous particles (bubbles). The notion of particle size applies to particles in colloids, in ecology, in granular material, and to particles that form a granular material.

Particle size analysis, particle size measurement, or simply particle sizing, is the collective name of the technical procedures, or laboratory techniques which determines the size range, and/or the average, or mean size of the particles in a powder or liquid sample.

Photoanalysis refers to the study of pictures to compile various types of data, for example, to measure the size distribution of virtually anything that can be captured by photo. Photoanalysis technology has changed the way mines and mills quantify fragmented material.

In mathematical morphology, granulometry is an approach to compute a size distribution of grains in binary images, using a series of morphological opening operations. It was introduced by Georges Matheron in the 1960s, and is the basis for the characterization of the concept of size in mathematical morphology.

Grain size is the diameter of individual grains of sediment, or the lithified particles in clastic rocks. The term may also be applied to other granular materials. This is different from the crystallite size, which refers to the size of a single crystal inside a particle or grain. A single grain can be composed of several crystals. Granular material can range from very small colloidal particles, through clay, silt, sand, gravel, and cobbles, to boulders.

Sensor-based sorting, is an umbrella term for all applications in which particles are detected using a sensor technique and rejected by an amplified mechanical, hydraulic or pneumatic process.

A powder is a dry, bulk solid composed of many very fine particles that may flow freely when shaken or tilted. Powders are a special sub-class of granular materials, although the terms powder and granular are sometimes used to distinguish separate classes of material. In particular, powders refer to those granular materials that have the finer grain sizes, and that therefore have a greater tendency to form clumps when flowing. Granulars refers to the coarser granular materials that do not tend to form clumps except when wet.

The Aphelion Imaging Software Suite is a software suite that includes three base products - Aphelion Lab, Aphelion Dev, and Aphelion SDK for addressing image processing and image analysis applications. The suite also includes a set of extension programs to implement specific vertical applications that benefit from imaging techniques.