Related Research Articles

Engineering is the use of scientific principles to design and build machines, structures, and other items, including bridges, tunnels, roads, vehicles, and buildings. The discipline of engineering encompasses a broad range of more specialized fields of engineering, each with a more specific emphasis on particular areas of applied mathematics, applied science, and types of application. See glossary of engineering.

The Industrial Revolution was the transition to new manufacturing processes in Great Britain, continental Europe, and the United States, that occurred during the period from around 1760 to about 1820–1840. This transition included going from hand production methods to machines; new chemical manufacturing and iron production processes; the increasing use of water power and steam power; the development of machine tools; and the rise of the mechanized factory system. Output greatly increased, and a result was an unprecedented rise in population and in the rate of population growth. The textile industry was the first to use modern production methods, and textiles became the dominant industry in terms of employment, value of output, and capital invested.

A steam engine is a heat engine that performs mechanical work using steam as its working fluid. The steam engine uses the force produced by steam pressure to push a piston back and forth inside a cylinder. This pushing force can be transformed, by a connecting rod and crank, into rotational force for work. The term "steam engine" is generally applied only to reciprocating engines as just described, not to the steam turbine. Steam engines are external combustion engines, where the working fluid is separated from the combustion products. The ideal thermodynamic cycle used to analyze this process is called the Rankine cycle. In general usage, the term steam engine can refer to either complete steam plants, such as railway steam locomotives and portable engines, or may refer to the piston or turbine machinery alone, as in the beam engine and stationary steam engine.

Manufacturing is the creation or production of goods with the help of equipment, labor, machines, tools, and chemical or biological processing or formulation. It is the essence of the secondary sector of the economy. The term may refer to a range of human activity, from handicraft to high-tech, but it is most commonly applied to industrial design, in which raw materials from the primary sector are transformed into finished goods on a large scale. Such goods may be sold to other manufacturers for the production of other more complex products, or distributed via the tertiary industry to end users and consumers.

George Westinghouse Jr. was an American entrepreneur and engineer based in Pennsylvania who created the railway air brake and was a pioneer of the electrical industry, receiving his first patent at the age of 19. Westinghouse saw the potential of using alternating current for electric power distribution in the early 1880s and put all his resources into developing and marketing it. This put Westinghouse's business in direct competition with Thomas Edison, who marketed direct current for electric power distribution. In 1911 Westinghouse received the American Institute of Electrical Engineers's (AIEE) Edison Medal "For meritorious achievement in connection with the development of the alternating current system." He founded the Westinghouse Electric Corporation in 1886.

Wrought iron is an iron alloy with a very low carbon content in contrast to that of cast iron. It is a semi-fused mass of iron with fibrous slag inclusions, which give it a wood-like "grain" that is visible when it is etched, rusted, or bent to failure. Wrought iron is tough, malleable, ductile, corrosion resistant, and easily forge welded, but is more difficult to weld electrically.

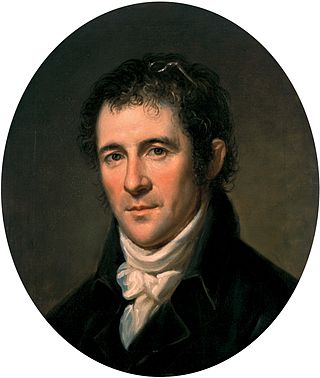

Benjamin Henry Boneval Latrobe was an Anglo-American neoclassical architect who emigrated to the United States. He was one of the first formally trained, professional architects in the new United States, drawing on influences from his travels in Italy, as well as British and French Neoclassical architects such as Claude Nicolas Ledoux. In his thirties, he emigrated to the new United States and designed the United States Capitol, on "Capitol Hill" in Washington, D.C., as well as the Old Baltimore Cathedral or The Baltimore Basilica,. It is the first Cathedral constructed in the United States for any Christian denomination. Latrobe also designed the largest structure in America at the time, the "Merchants' Exchange" in Baltimore. With extensive balconied atriums through the wings and a large central rotunda under a low dome which dominated the city, it was completed in 1820 after five years of work and endured into the early twentieth century.

A steamboat is a boat that is propelled primarily by steam power, typically driving propellers or paddlewheels. Steamboats sometimes use the prefix designation SS, S.S. or S/S or PS ; however, these designations are most often used for steamships.

The Second Industrial Revolution, also known as the Technological Revolution, was a phase of rapid scientific discovery, standardization, mass production and industrialization from the late 19th century into the early 20th century. The First Industrial Revolution, which ended in the middle of the 19th century, was punctuated by a slowdown in important inventions before the Second Industrial Revolution in 1870. Though a number of its events can be traced to earlier innovations in manufacturing, such as the establishment of a machine tool industry, the development of methods for manufacturing interchangeable parts, as well as the invention of the Bessemer process to produce steel, the Second Industrial Revolution is generally dated between 1870 and 1914.

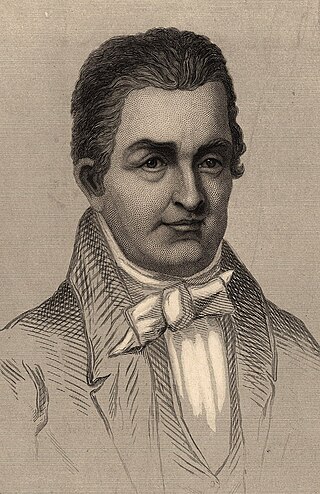

Oliver Evans was an American inventor, engineer and businessman born in rural Delaware and later rooted commercially in Philadelphia. He was one of the first Americans building steam engines and an advocate of high pressure steam. A pioneer in the fields of automation, materials handling and steam power, Evans was one of the most prolific and influential inventors in the early years of the United States. He left behind a long series of accomplishments, most notably designing and building the first fully automated industrial process, the first high-pressure steam engine, and the first amphibious vehicle and American automobile.

The technological and industrial history of the United States describes the United States' emergence as one of the most technologically advanced nations in the world. The availability of land and literate labor, the absence of a landed aristocracy, the prestige of entrepreneurship, the diversity of climate and large easily accessed upscale and literate markets all contributed to America's rapid industrialization. The availability of capital, development by the free market of navigable rivers and coastal waterways, as well as the abundance of natural resources facilitated the cheap extraction of energy all contributed to America's rapid industrialization. Fast transport by the very large railroad built in the mid-19th century, and the Interstate Highway System built in the late 20th century, enlarged the markets and reduced shipping and production costs. The legal system facilitated business operations and guaranteed contracts. Cut off from Europe by the embargo and the British blockade in the War of 1812 (1807–15), entrepreneurs opened factories in the Northeast that set the stage for rapid industrialization modeled on British innovations.

Steam power developed slowly over a period of several hundred years, progressing through expensive and fairly limited devices in the early 17th century, to useful pumps for mining in 1700, and then to Watt's improved steam engine designs in the late 18th century. It is these later designs, introduced just when the need for practical power was growing due to the Industrial Revolution, that truly made steam power commonplace.

Textile manufacture during the British Industrial Revolution was centred in south Lancashire and the towns on both sides of the Pennines in the United Kingdom. The main drivers of the Industrial Revolution were textile manufacturing, iron founding, steam power, oil drilling, the discovery of electricity and its many industrial applications, the telegraph and many others. Railroads, steam boats, the telegraph and other innovations massively increased worker productivity and raised standards of living by greatly reducing time spent during travel, transportation and communications.

Improvements to the steam engine were some of the most important technologies of the Industrial Revolution, although steam did not replace water power in importance in Britain until after the Industrial Revolution. From Englishman Thomas Newcomen's atmospheric engine, of 1712, through major developments by Scottish inventor and mechanical engineer James Watt, the steam engine began to be used in many industrial settings, not just in mining, where the first engines had been used to pump water from deep workings. Early mills had run successfully with water power, but by using a steam engine a factory could be located anywhere, not just close to a water source. Water power varied with the seasons and was not always available.

Robert Henry Thurston was an American engineer, and the first Professor of Mechanical Engineering at Stevens Institute of Technology.

B. Hick and Sons, subsequently Hick, Hargreaves & Co, was a British engineering company based at the Soho Ironworks in Bolton, England. Benjamin Hick, a partner in Rothwell, Hick and Rothwell, later Rothwell, Hick & Co., set up the company in partnership with two of his sons, John (1815–1894) and Benjamin (1818–1845) in 1833.

The Monongahela and Ohio Steam Boat Company was the second company to engage in steamboat commerce on the rivers west of the Allegheny Mountains. The company was founded in 1813 under the leadership of Elisha Hunt and headquartered in his store which was located close to the boat landing in Brownsville, Pennsylvania. Daniel French designed and built the engines and power trains for both the Despatch, or Dispatch, and the Enterprise. During the Battle of New Orleans in 1815, the shareholders of the Monongahela and Ohio Steam Boat Company sent the Enterprise to aid the American cause. In 1815, the Enterprise demonstrated for the first time by her epic 2,200-mile voyage from New Orleans to Brownsville that steamboat commerce was practical on America's western rivers.

The first recorded rudimentary steam engine was the aeolipile mentioned by Vitruvius between 30 and 15 BC and, described by Heron of Alexandria in 1st-century Roman Egypt. Several steam-powered devices were later experimented with or proposed, such as Taqi al-Din's steam jack, a steam turbine in 16th-century Ottoman Egypt, and Thomas Savery's steam pump in 17th-century England. In 1712, Thomas Newcomen's atmospheric engine became the first commercially successful engine using the principle of the piston and cylinder, which was the fundamental type of steam engine used until the early 20th century. The steam engine was used to pump water out of coal mines.

Steamboats played a major role in the 19th-century development of the Mississippi River and its tributaries, allowing practical large-scale transport of passengers and freight both up- and down-river. Using steam power, riverboats were developed during that time which could navigate in shallow waters as well as upriver against strong currents. After the development of railroads, passenger traffic gradually switched to this faster form of transportation, but steamboats continued to serve Mississippi River commerce into the early 20th century. A small number of steamboats are still used for tourist excursions in the 21st century.

The Worthington Corporation was a diversified American manufacturer that had its roots in Worthington and Baker, a steam pump manufacturer founded in 1845. In 1967 it merged with Studebaker and Wagner Electric to form Studebaker-Worthington. This company was in turn acquired by McGraw-Edison in 1979.

References

- ↑ Latrobe, Benjamin Henry; Van Horne, John C; Formwalt, Lee W (1984–1988). The correspondence and miscellaneous papers of Benjamin Henry Latrobe. Maryland Historical Society. New Haven: Yale University Press. p. 513.

- ↑ Meyer, David R (2006). Networked machinists : high-technology industries in Antebellum America. Johns Hopkins studies in the history of technology. Baltimore: Johns Hopkins University Press. p. 44. ISBN 978-0-8018-8471-9. OCLC 65340979.

- ↑ Armstrong, John (1816). The Pittsburgh town & country almanac, for rogues and honest folks(almanac). Pittsburgh, Pennsylvania: R. & J. Patterson. ISBN 9780801884719. OCLC 15448103.

{{cite book}}:|format=requires|url=(help)