Related Research Articles

Powder metallurgy (PM) is a term covering a wide range of ways in which materials or components are made from metal powders. PM processes are sometimes used to reduce or eliminate the need for subtractive processes in manufacturing, lowering material losses and reducing the cost of the final product. This occurs especially often with small metal parts, like gears for small machines. Some porous products, allowing liquid or gas to permeate them, are produced in this way. They are also used when melting a material is impractical, due to it having a high melting point, or an alloy of two mutually insoluble materials, such as a mixture of copper and graphite.

A coating is a covering that is applied to the surface of an object, or substrate. The purpose of applying the coating may be decorative, functional, or both. Coatings may be applied as liquids, gases or solids e.g. powder coatings.

A superalloy, or high-performance alloy, is an alloy with the ability to operate at a high fraction of its melting point. Key characteristics of a superalloy include mechanical strength, thermal creep deformation resistance, surface stability, and corrosion and oxidation resistance.

Cathodic arc deposition or Arc-PVD is a physical vapor deposition technique in which an electric arc is used to vaporize material from a cathode target. The vaporized material then condenses on a substrate, forming a thin film. The technique can be used to deposit metallic, ceramic, and composite films.

Titanium powder metallurgy (P/M) offers the possibility of creating net shape or near net shape parts without the material loss and cost associated with having to machine intricate components from wrought billet. Powders can be produced by the blended elemental technique or by pre-alloying and then consolidated by metal injection moulding, hot isostatic pressing, direct powder rolling or laser engineered net shaping.

Spray forming, also known as spray casting, spray deposition and in-situ compaction, is a method of casting near net shape metal components with homogeneous microstructures via the deposition of semi-solid sprayed droplets onto a shaped substrate. In spray forming an alloy is melted, normally in an induction furnace, then the molten metal is slowly poured through a conical tundish into a small-bore ceramic nozzle. The molten metal exits the furnace as a thin free-falling stream and is broken up into droplets by an annular array of gas jets, and these droplets then proceed downwards, accelerated by the gas jets to impact onto a substrate. The process is arranged such that the droplets strike the substrate whilst in the semi-solid condition, this provides sufficient liquid fraction to 'stick' the solid fraction together. Deposition continues, gradually building up a spray formed billet of metal on the substrate.

Thermal spraying techniques are coating processes in which melted materials are sprayed onto a surface. The "feedstock" is heated by electrical or chemical means.

Thermal barrier coatings (TBCs) are advanced materials systems usually applied to metallic surfaces on parts operating at elevated temperatures, such as gas turbine combustors and turbines, and in automotive exhaust heat management. These 100 μm to 2 mm thick coatings of thermally insulating materials serve to insulate components from large and prolonged heat loads and can sustain an appreciable temperature difference between the load-bearing alloys and the coating surface. In doing so, these coatings can allow for higher operating temperatures while limiting the thermal exposure of structural components, extending part life by reducing oxidation and thermal fatigue. In conjunction with active film cooling, TBCs permit working fluid temperatures higher than the melting point of the metal airfoil in some turbine applications. Due to increasing demand for more efficient engines running at higher temperatures with better durability/lifetime and thinner coatings to reduce parasitic mass for rotating/moving components, there is significant motivation to develop new and advanced TBCs. The material requirements of TBCs are similar to those of heat shields, although in the latter application emissivity tends to be of greater importance.

Gas dynamic cold spraying or cold spraying (CS) is a coating deposition method. Solid powders are accelerated in a supersonic gas jet to velocities up to ca. 1200 m/s. During impact with the substrate, particles undergo plastic deformation and adhere to the surface. To achieve a uniform thickness the spraying nozzle is scanned along the substrate. Metals, polymers, ceramics, composite materials and nanocrystalline powders can be deposited using cold spraying. The kinetic energy of the particles, supplied by the expansion of the gas, is converted to plastic deformation energy during bonding. Unlike thermal spraying techniques, e.g., plasma spraying, arc spraying, flame spraying, or high velocity oxygen fuel (HVOF), the powders are not melted during the spraying process.

CFD-ACE+ is a commercial computational fluid dynamics solver developed by Applied Materials. It solves the conservation equations of mass, momentum, energy, chemical species and other scalar transport equations using the finite volume method. These equations enable coupled simulations of fluid, thermal, chemical, biological, electrical and mechanical phenomena.

Solution precursor plasma spray (SPPS) is a thermal spray process where a feedstock solution is heated and then deposited onto a substrate. Basic properties of the process are fundamentally similar to other plasma spraying processes. However, instead of injecting a powder into the plasma plume, a liquid precursor is used. The benefits of utilizing the SPPS process include the ability to create unique nanometer sized microstructures without the injection feed problems normally associated with powder systems and flexible, rapid exploration of novel precursor compositions.

Electrostatic spray-assisted vapour deposition (ESAVD) is a technique to deposit both thin and thick layers of a coating onto various substrates. In simple terms chemical precursors are sprayed across an electrostatic field towards a heated substrate, the chemicals undergo a controlled chemical reaction and are deposited on the substrate as the required coating. Electrostatic spraying techniques were developed in the 1950s for the spraying of ionised particles on to charged or heated substrates.

The VR is a series of twin-turbo DOHC V6 automobile engines from Nissan with displacements of 3.0 and 3.8 L. An evolution of the widely successful VQ series, it also draws on developments from the VRH, JGTC, and Nissan R390 GT1 Le Mans racing engines.

Ultrasonic nozzles are a type of spray nozzle that use high frequency vibrations produced by piezoelectric transducers acting upon the nozzle tip that create capillary waves in a liquid film. Once the amplitude of the capillary waves reaches a critical height, they become too tall to support themselves and tiny droplets fall off the tip of each wave resulting in atomization.

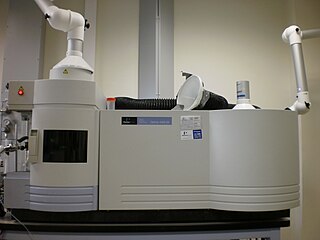

Atomic emission spectroscopy (AES) is a method of chemical analysis that uses the intensity of light emitted from a flame, plasma, arc, or spark at a particular wavelength to determine the quantity of an element in a sample. The wavelength of the atomic spectral line in the emission spectrum gives the identity of the element while the intensity of the emitted light is proportional to the number of atoms of the element. The sample may be excited by various methods.

Flame-Spray Industries, Inc. is a thermal spray company, that invented the plasma transferred wire arc thermal spraying process. They received the 2009 IPO National Inventor of the Year award for this process. Flame-spray Industries is located in Port Washington, New York and its primary industry is thermal spray technologies for engine coating.

Gas metal arc welding (GMAW), sometimes referred to by its subtypes metal inert gas (MIG) and metal active gas (MAG) is a welding process in which an electric arc forms between a consumable MIG wire electrode and the workpiece metal(s), which heats the workpiece metal(s), causing them to fuse. Along with the wire electrode, a shielding gas feeds through the welding gun, which shields the process from atmospheric contamination.

Detonation spraying is one of the many forms of thermal spraying techniques that are used to apply a protective coating at supersonic velocities to a material in order to change its surface characteristics. This is primarily to improve the durability of a component. It was first invented in 1955 by H.B. Sargent, R.M. Poorman and H. Lamprey and is applied to a component using a specifically designed detonation gun (D-gun). The component being sprayed must be prepared correctly by removing all surface oils, greases, debris and roughing up the surface in order to achieve a strongly bonded detonation spray coating. This process involves the highest velocities and temperatures (≈4000 °C) of coating materials compared to all other forms of thermal spraying techniques. Which means detonation spraying is able to apply low porous and low oxygen content protective coatings that protect against corrosion, abrasion and adhesion under low load.

Cold spray additive manufacturing (CSAM) is a particular application of cold spraying, able to fabricate freestanding parts or to build features on existing components. During the process, fine powder particles are accelerated in a high-velocity compressed gas stream, and upon the impact on a substrate or backing plate, deform and bond together creating a layer. Moving the nozzle over a substrate repeatedly, a deposit is building up layer-by-layer, to form a part or component. If an industrial robot or computer controlled manipulator controls the spray gun movements, complex shapes can be created. To achieve a 3D shape, there are two different approaches. First, to fix the substrate and move the cold spray gun/nozzle using a robotic arm; the second one is to move the substrate with a robotic arm, and keep the spray-gun nozzle fixed. There is also a possibility to combine these two approaches either using two robotic arms or other manipulators. The process always requires a substrate and uses only powder as raw material.

Laser metal deposition (LMD) is an additive manufacturing process in which a feedstock material is melted with a laser and then deposited onto a substrate. A variety of pure metals and alloys can be used as the feedstock, as well as composite materials such as metal matrix composites. Laser sources with a wide variety of intensities, wavelengths, and optical configurations can be used. While LMD is typically a melt-based process, this is not a requirement, as discussed below. Melt-based processes typically have a strength advantage, due to achieving a full metallurgical fusion.

References

- ↑ IPO Education Foundation Honors Top Inventors of 2009

- ↑ Skarvelis, P; Papadimitriou, G.D (2009). "Plasma transferred arc composite coatings with self lubricating properties, based on Fe and Ti sulfides: Microstructure and tribological behavior". Surface and Coatings Technology. 203 (10–11): 1384–1394. doi:10.1016/j.surfcoat.2008.11.010.

- ↑ Wojdyla, Ben (2010-02-10). "The Ford Engine Technology Good Enough For The Nissan GT-R". Jalopnik. Retrieved 2022-11-04.

- ↑ Ford launches plasma-sprayed cylinder bores on 2011 Shelby V8, February 17, 2010

- ↑ Webster, Larry (2010-04-16). "Long Live the Mustangs' V8s". Popular Mechanics. Retrieved 2022-11-04.

- ↑ Turpen, Aaron (2015-12-03). "Ford using plasma to refurbish dead engines". New Atlas. Retrieved 2022-11-04.