Related Research Articles

A pump is a device that moves fluids, or sometimes slurries, by mechanical action, typically converted from electrical energy into Hydraulic energy. Pumps can be classified into three major groups according to the method they use to move the fluid: direct lift, displacement, and gravity pumps.

A turbocharger, colloquially known as a turbo, is a turbine-driven, forced induction device that increases an internal combustion engine's efficiency and power output by forcing extra compressed air into the combustion chamber. This improvement over a naturally aspirated engine's power output is because the compressor can force more air—and proportionately more fuel—into the combustion chamber than atmospheric pressure alone.

A burette is a graduated glass tube with a tap at one end, for delivering known volumes of a liquid, especially in titrations. It is a long, graduated glass tube, with a stopcock at its lower end and a tapered capillary tube at the stopcock's outlet. The flow of liquid from the tube to the burette tip is controlled by the stopcock valve. There are two main types of burette; the volumetric burette and the Piston burette or Digital burette.

A pipette is a laboratory tool commonly used in chemistry, biology and medicine to transport a measured volume of liquid, often as a media dispenser. Pipettes come in several designs for various purposes with differing levels of accuracy and precision, from single piece glass pipettes to more complex adjustable or electronic pipettes. Many pipette types work by creating a partial vacuum above the liquid-holding chamber and selectively releasing this vacuum to draw up and dispense liquid. Measurement accuracy varies greatly depending on the instrument.

A syringe is a simple reciprocating pump consisting of a plunger that fits tightly within a cylindrical tube called a barrel. The plunger can be linearly pulled and pushed along the inside of the tube, allowing the syringe to take in and expel liquid or gas through a discharge orifice at the front (open) end of the tube. The open end of the syringe may be fitted with a hypodermic needle, a nozzle or tubing to direct the flow into and out of the barrel. Syringes are frequently used in clinical medicine to administer injections, infuse intravenous therapy into the bloodstream, apply compounds such as glue or lubricant, and draw/measure liquids.

A fuel pump is a component in motor vehicles that transfers liquid from the fuel tank to the carburetor of the internal combustion engine.

A naturally-aspirated engine, also known as a normally-aspirated engine, is an internal combustion engine in which air intake depends solely on atmospheric pressure and does not have forced induction through a turbocharger or a supercharger. Many sports cars specifically use naturally aspirated engines to avoid turbo lag.

Forced induction is the process of delivering compressed air to the intake of an internal combustion engine. A forced induction engine uses a gas compressor to increase the pressure, temperature and density of the air. An engine without forced induction is considered a naturally aspirated engine.

An ampoule is a small sealed vial which is used to contain and preserve a sample, usually a solid or liquid. Ampoules are made of glass.

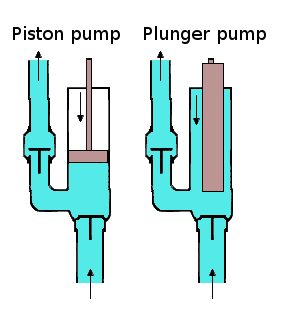

A piston pump is a type of positive displacement pump where the high-pressure seal reciprocates with the piston. Piston pumps can be used to move liquids or compress gases. They can operate over a wide range of pressures. High pressure operation can be achieved without a strong effect on flow rate. Piston pumps can also deal with viscous media and media containing solid particles. This pump type functions through a piston cup, oscillation mechanism where down-strokes cause pressure differentials, filling of pump chambers, where up-stroke forces the pump fluid out for use. Piston pumps are often used in scenarios requiring high, consistent pressure and in water irrigation or delivery systems.

An eye dropper, also known as a Pasteur pipette, or dropper, is a device used to transfer small quantities of liquids. They are used in the laboratory and also to dispense small amounts of liquid medicines. A very common use was to dispense eye drops into the eye. The commonly recognized form is a glass tube tapered to a narrow point and fitted with a rubber bulb at the top, although many styles of both plastic and glass droppers exist. The combination of the pipette and rubber bulb has also been referred to as a teat pipette. The Pasteur pipette name is from the French scientist Louis Pasteur, who used a variant of them extensively during his research. In the past, there was no equipment to transfer a chemical solution without exposing it to the external environment. The hygiene and purity of chemical compounds is necessary for the expected result of each experiment. The eye dropper, both glass and plastic types, can be sterilized and plugged with a rubber bulb at the open end of the pipette preventing any contamination from the atmosphere. Generally, they are considered cheap enough to be disposable, however, so long as the glass point is not chipped, the eye dropper may be washed and reused indefinitely.

Reverse transfection is a technique for the transfer of genetic material into cells. As DNA is printed on a glass slide for the transfection process to occur before the addition of adherent cells, the order of addition of DNA and adherent cells is reverse that of conventional transfection. Hence, the word “reverse” is used.

Drum pump, barrel pump, and transfer pump refer to pumps that are used to empty barrels, tanks, IBCs and drums. Many liquids used on manufacturing and processing plants are delivered in 100 or 200 litre barrels and are too heavy to tip to empty the liquids inside. Drum pumps range from simple siphon based devices to sophisticated highly-engineered machinery.

Piston-driven air displacement pipettes are a type of micropipette, which are tools to handle volumes of liquid in the microliter scale. They are more commonly used in biology and biochemistry, and less commonly in chemistry; the equipment is susceptible to damage from many organic solvents.

An automated pipetting system is generally a device which performs programmed transfers of liquid between preselected groups of containers.

Boom method is a solid phase extraction method for isolating nucleic acid from a biological sample. This method is characterized by "absorbing the nucleic acids (NA) to the silica beads".

Forward pipetting is a technique to dispense a measured quantity of liquid by means of air displacement pipette. The technique is mainly recommended for aqueous solutions, such as buffers, or diluted acids or alkalis. In case of solutions with a high viscosity or a tendency to foam, reverse pipetting is more suitable.

Reverse pipetting is a technique to dispense a measured quantity of liquid by means of air displacement pipette. The technique is mainly recommended for solutions with a high viscosity or a tendency to foam: as it reduces the risk of splashing, foam or bubble formation. Reverse pipetting is more precise in dispensing small volumes of liquids containing proteins and biological solutions compared to forward pipetting, which is mostly used for aqueous solutions, such as buffers, diluted acids or alkalis.

A media dispenser or a culture media dispenser is a device for repeatedly delivering small fixed volumes of liquid such as a laboratory growth medium like molten agar or caustic or volatile solvents like toluene into a series of receptacles. It is often important that such dispensers operate without biological or chemical contamination, and so must be internally sealed from the environment and designed for easy cleaning and sterilization before use. At a minimum, a media dispenser consists of some kind of pump connected to a length of discharge tubing or a spout. Dispensers used in laboratories are also frequently connected to microcontrollers to regulate the speed and volume of the medium as it leaves the pump.

Heinrich Schnitger was a German physician. He is considered the inventor of the piston stroke Micropipette, a laboratory device for dispensing small amounts of liquid.

References

- 1 2 3 "Positive Displacement Pipette" . Retrieved 19 December 2017.

- ↑ "Selecting the Right Pipette" (PDF). Retrieved 19 December 2017.

- 1 2 3 "The working principle of positive displacement pipettes" (PDF). Retrieved 19 December 2017.

- 1 2 "Positive-displacement Pipettes for Accurate Transfer of "Problem Liquids"" (PDF). Retrieved 19 December 2017.

- ↑ "BRAND Positive Displacement Pipettes" . Retrieved 19 December 2017.

- ↑ "Precise and Repeatable Pipetting of Problem Liquids" . Retrieved 19 December 2017.

- ↑ "Specialty Pipettes" . Retrieved 19 December 2017.

- ↑ Segur, J. B.; Oberstar, H. E. (1951). "Viscosity of Glycerol and Its Aqueous Solutions". Industrial & Engineering Chemistry. 43 (9): 2117–2120. doi:10.1021/ie50501a040.

- 1 2 3 "Effect of Liquid Properties in Pipetting Liquid Handling Note – No. 1" (PDF). Retrieved 19 December 2017.

- 1 2 3 4 "ACHIEVE PIPETTING PRECISION OF PROBLEM LIQUIDS WITH MICROMAN® E" (PDF). Retrieved 16 January 2018.

- 1 2 3 "How Positive Displacement Pipettes Work" . Retrieved 19 December 2017.

- ↑ "Preventing Contamination in Pipetting" . Retrieved 19 December 2017.

- 1 2 3 4 "Extreme Pipetting II: Thermal Exploration" . Retrieved 19 December 2017.

- 1 2 "Securing accuracy and precision when pipetting hot and cold liquids with Microman®" . Retrieved 19 December 2017.

- ↑ "Pipetting Techniques" (PDF). Retrieved 19 December 2017.