Related Research Articles

Liquid hydrogen (H2(l)) is the liquid state of the element hydrogen. Hydrogen is found naturally in the molecular H2 form.

The flash point of a material is the "lowest liquid temperature at which, under certain standardized conditions, a liquid gives off vapours in a quantity such as to be capable of forming an ignitable vapour/air mixture".

A lighter is a portable device which uses mechanical or electrical means to create a controlled flame, and can be used to ignite a variety of flammable items, such as cigarettes, butane gas, fireworks, candles, or campfires. A lighter typically consists of a metal or plastic container filled with a flammable liquid, a compressed flammable gas, or in rarer cases a flammable solid ; a means of ignition to produce the flame; and some provision for extinguishing the flame or else controlling it to such a degree that the user may extinguish it with their breath. Alternatively, a lighter can be one which uses electricity to create an electric arc utilizing the created plasma as the source of ignition or a heating element can be used in a similar vein to heat the target to its ignition temperatures, as first formally utilized by Friedrich Wilhelm Schindler to light cigars and now more commonly seen incorporated into the automobile auxiliary power outlet to ignite the target material. Different lighter fuels have different characteristics which is the main influence behind the creation and purchasing of a variety of lighter types.

An inerting system decreases the probability of combustion of flammable materials stored in a confined space. The most common such system is a fuel tank containing a combustible liquid, such as gasoline, diesel fuel, aviation fuel, jet fuel, or rocket propellant. After being fully filled, and during use, there is a space above the fuel, called the ullage, that contains evaporated fuel mixed with air, which contains the oxygen necessary for combustion. Under the right conditions this mixture can ignite. An inerting system replaces the air with a gas that cannot support combustion, such as nitrogen.

Firedamp is any flammable gas found in coal mines, typically coalbed methane. It is particularly found in areas where the coal is bituminous. The gas accumulates in pockets in the coal and adjacent strata and when they are penetrated the release can trigger explosions. Historically, if such a pocket was highly pressurized, it was termed a "bag of foulness".

In electrical and safety engineering, hazardous locations are places where fire or explosion hazards may exist. Sources of such hazards include gases, vapors, dust, fibers, and flyings, which are combustible or flammable. Electrical equipment installed in such locations can provide an ignition source, due to electrical arcing, or high temperatures. Standards and regulations exist to identify such locations, classify the hazards, and design equipment for safe use in such locations.

Mixtures of dispersed combustible materials and oxygen in the air will burn only if the fuel concentration lies within well-defined lower and upper bounds determined experimentally, referred to as flammability limits or explosive limits. Combustion can range in violence from deflagration through detonation.

The ATEX directives are two of the EU directives describing the minimum safety requirements for workplaces and equipment used in explosive atmospheres. The name is an initialization of the term ATmosphères EXplosibles.

Intrinsic safety (IS) is a protection technique for safe operation of electrical equipment in hazardous areas by limiting the energy, electrical and thermal, available for ignition. In signal and control circuits that can operate with low currents and voltages, the intrinsic safety approach simplifies circuits and reduces installation cost over other protection methods. Areas with dangerous concentrations of flammable gases or dust are found in applications such as petrochemical refineries and mines. As a discipline, it is an application of inherent safety in instrumentation. High-power circuits such as electric motors or lighting cannot use intrinsic safety methods for protection.

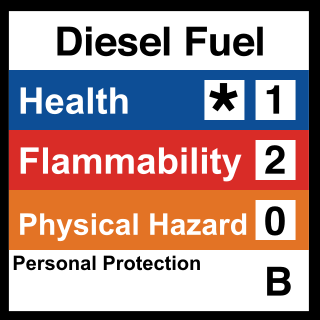

The Hazardous Materials Identification System (HMIS) is a proprietary numerical hazard rating that incorporates the use of labels with color bars developed by the American Coatings Association as a compliance aid for the OSHA Hazard Communication (HazCom) Standard. The name and abbreviation is a trademark of the American Coatings Association.

A combustible material is a material that can burn in air under certain conditions. A material is flammable if it ignites easily at ambient temperatures. In other words, a combustible material ignites with some effort and a flammable material catches fire immediately on exposure to flame.

A dust explosion is the rapid combustion of fine particles suspended in the air within an enclosed location. Dust explosions can occur where any dispersed powdered combustible material is present in high-enough concentrations in the atmosphere or other oxidizing gaseous medium, such as pure oxygen. In cases when fuel plays the role of a combustible material, the explosion is known as a fuel-air explosion.

A shutdown valve is an actuated valve designed to stop the flow of a hazardous fluid upon the detection of a dangerous event. This provides protection against possible harm to people, equipment or the environment. Shutdown valves form part of a safety instrumented system. The process of providing automated safety protection upon the detection of a hazardous event is called functional safety.

A gas detector is a device that detects the presence of gases in an area, often as part of a safety system. A gas detector can sound an alarm to operators in the area where the leak is occurring, giving them the opportunity to leave. This type of device is important because there are many gases that can be harmful to organic life, such as humans or animals.

The Hornsby-Akroyd oil engine, named after its inventor Herbert Akroyd Stuart and the manufacturer Richard Hornsby & Sons, was the first successful design of an internal combustion engine using heavy oil as a fuel. It was the first to use a separate vapourising combustion chamber and is the forerunner of all hot-bulb engines, which are considered predecessors of the similar Diesel engine, developed a few years later.

A flame arrester, deflagration arrester, or flame trap is a device or form of construction that will allow free passage of a gas or gaseous mixture but will interrupt or prevent the passage of flame. It prevents the transmission of flame through a flammable gas/air mixture by quenching the flame on the high surface area provided by an array of small passages through which the flame must pass. The emerging gases are cooled enough to prevent ignition on the protected side.

DSEAR, the Dangerous Substances and Explosive Atmospheres Regulations 2002, is the United Kingdom's implementation of the European Union-wide ATEX directive.

Hydrogen safety covers the safe production, handling and use of hydrogen, particularly hydrogen gas fuel and liquid hydrogen. Hydrogen possesses the NFPA 704's highest rating of four on the flammability scale because it is flammable when mixed even in small amounts with ordinary air. Ignition can occur at a volumetric ratio of hydrogen to air as low as 4% due to the oxygen in the air and the simplicity and chemical properties of the reaction. However, hydrogen has no rating for innate hazard for reactivity or toxicity. The storage and use of hydrogen poses unique challenges due to its ease of leaking as a gaseous fuel, low-energy ignition, wide range of combustible fuel-air mixtures, buoyancy, and its ability to embrittle metals that must be accounted for to ensure safe operation.

A positive pressure enclosure, also known as a welding habitat or hot work habitat, is a chamber used to provide a safe working environment for performing hot work in the presence of explosive gases or vapors. They are commonly used in welding environments and are associated with the offshore oil industry.

An internal combustion engine is a heat engine in which the combustion of a fuel occurs with an oxidizer in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal combustion engine, the expansion of the high-temperature and high-pressure gases produced by combustion applies direct force to some component of the engine. The force is typically applied to pistons, turbine blades, a rotor, or a nozzle. This force moves the component over a distance. This process transforms chemical energy into kinetic energy which is used to propel, move or power whatever the engine is attached to.

References

- ↑ "Caterpillar Acquires Pyroban Statement" . Retrieved 17 March 2014.

- ↑ "New ownership for Pyroban | Pyroban Group Ltd | Explosion Protection & Environmental Solutions" . Retrieved 17 March 2014.

- ↑ "Longacre Group Announces the Acquisition of Both Pyroban and Pyropress". 21 November 2017.

- ↑ "Pyroban stops 8-hour maintenance regimes on explosion proof engines". 15 April 2020.

- ↑ "Ever Clear reduces maintenance costs on ATEX generator sets in Malaysia". 2 March 2022.

- ↑ "About - Pioneer Safety Group". 12 January 2024.