Ubiquitous computing is a concept in software engineering, hardware engineering and computer science where computing is made to appear anytime and everywhere. In contrast to desktop computing, ubiquitous computing can occur using any device, in any location, and in any format. A user interacts with the computer, which can exist in many different forms, including laptop computers, tablets, smart phones and terminals in everyday objects such as a refrigerator or a pair of glasses. The underlying technologies to support ubiquitous computing include Internet, advanced middleware, operating system, mobile code, sensors, microprocessors, new I/O and user interfaces, computer networks, mobile protocols, location and positioning, and new materials.

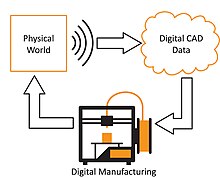

Computer-Aided Design (CAD) is the use of computers to aid in the creation, modification, analysis, or optimization of a design. This software is used to increase the productivity of the designer, improve the quality of design, improve communications through documentation, and to create a database for manufacturing. Designs made through CAD software are helpful in protecting products and inventions when used in patent applications. CAD output is often in the form of electronic files for print, machining, or other manufacturing operations. The terms computer-aided drafting (CAD) and computer-aided design and drafting (CADD) are also used.

An application-specific integrated circuit is an integrated circuit (IC) chip customized for a particular use, rather than intended for general-purpose use, such as a chip designed to run in a digital voice recorder or a high-efficiency video codec. Application-specific standard product chips are intermediate between ASICs and industry standard integrated circuits like the 7400 series or the 4000 series. ASIC chips are typically fabricated using metal–oxide–semiconductor (MOS) technology, as MOS integrated circuit chips.

In marketing, manufacturing, call centre operations, and management, mass customization makes use of flexible computer-aided systems to produce custom output. Such systems combine the low unit costs of mass production processes with the flexibility of individual customization.

Mass customization is the new frontier in business for both manufacturing and service industries. At its core, is a tremendous increase in variety and customization without a corresponding increase in costs. At its limit, it is the mass production of individually customized goods and services. At its best, it provides strategic advantage and economic value.

Solid modeling is a consistent set of principles for mathematical and computer modeling of three-dimensional shapes (solids). Solid modeling is distinguished within the broader related areas of geometric modeling and computer graphics, such as 3D modeling, by its emphasis on physical fidelity. Together, the principles of geometric and solid modeling form the foundation of 3D-computer-aided design and in general support the creation, exchange, visualization, animation, interrogation, and annotation of digital models of physical objects.

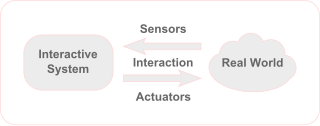

Interaction design, often abbreviated as IxD, is "the practice of designing interactive digital products, environments, systems, and services." While interaction design has an interest in form, its main area of focus rests on behavior. Rather than analyzing how things are, interaction design synthesizes and imagines things as they could be. This element of interaction design is what characterizes IxD as a design field, as opposed to a science or engineering field.

A smart device is an electronic device, generally connected to other devices or networks via different wireless protocols that can operate to some extent interactively and autonomously. Several notable types of smart devices are smartphones, smart speakers, smart cars, smart thermostats, smart doorbells, smart locks, smart refrigerators, phablets and tablets, smartwatches, smart bands, smart keychains, smart glasses, and many others. The term can also refer to a device that exhibits some properties of ubiquitous computing, including—although not necessarily—machine learning.

A mobile device is a computer, small enough to hold and operate in the hand. Mobile devices typically have a flat LCD or OLED screen, a touchscreen interface, and digital or physical buttons. They may also have a physical keyboard. Many such devices can connect to the Internet and connect with other devices such as car entertainment systems or headsets via Wi-Fi, Bluetooth, cellular networks or near field communication. Integrated cameras, the ability to place and receive voice and video telephone calls, video games, and Global Positioning System (GPS) capabilities are common. Power is typically provided by a lithium-ion battery. Mobile devices may run mobile operating systems that allow third-party applications to be installed and run.

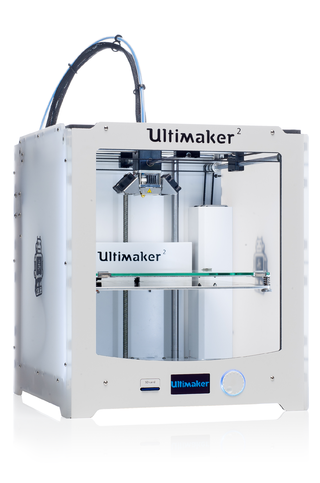

3D printing or additive manufacturing is the construction of a three-dimensional object from a CAD model or a digital 3D model. It can be done in a variety of processes in which material is deposited, joined or solidified under computer control, with material being added together, typically layer by layer.

Human-centered computing (HCC) studies the design, development, and deployment of mixed-initiative human-computer systems. It is emerged from the convergence of multiple disciplines that are concerned both with understanding human beings and with the design of computational artifacts. Human-centered computing is closely related to human-computer interaction and information science. Human-centered computing is usually concerned with systems and practices of technology use while human-computer interaction is more focused on ergonomics and the usability of computing artifacts and information science is focused on practices surrounding the collection, manipulation, and use of information.

In computing, ambient intelligence (AmI) refers to electronic environments that are sensitive and responsive to the presence of people. Ambient intelligence is a projection of the future of consumer electronics, telecommunications, and computing, originally developed in the late 1990s by Eli Zelkha and his team at Palo Alto Ventures for the time frame 2010–2020. This concept is intended to enable devices to work in concert with people in carrying out their everyday life activities, tasks, and rituals in an intuitive way by using information and intelligence hidden in the network connecting these devices. It is theorized that as these devices grow smaller, more connected, and more integrated into our environment, the technological framework behind them will disappear into our surroundings until only the user interface remains perceivable by users.

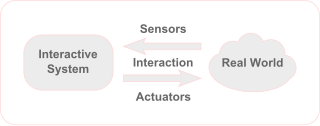

Physical computing involves interactive systems that can sense and respond to the world around them. While this definition is broad enough to encompass systems such as smart automotive traffic control systems or factory automation processes, it is not commonly used to describe them. In a broader sense, physical computing is a creative framework for understanding human beings' relationship to the digital world. In practical use, the term most often describes handmade art, design or DIY hobby projects that use sensors and microcontrollers to translate analog input to a software system, and/or control electro-mechanical devices such as motors, servos, lighting or other hardware.

Smart environments link computers and other smart devices to everyday settings and tasks. Smart environments include smart homes, smart cities and smart manufacturing.

Rapid prototyping is a group of techniques used to quickly fabricate a scale model of a physical part or assembly using three-dimensional computer aided design (CAD) data. Construction of the part or assembly is usually done using 3D printing or "additive layer manufacturing" technology.

Digital modeling and fabrication is a design and production process that combines 3D modeling or computing-aided design (CAD) with additive and subtractive manufacturing. Additive manufacturing is also known as 3D printing, while subtractive manufacturing may also be referred to as machining, and many other technologies can be exploited to physically produce the designed objects.

A smart object is an object that enhances the interaction with not only people but also with other smart objects. Also known as smart connected products or smart connected things (SCoT), they are products, assets and other things embedded with processors, sensors, software and connectivity that allow data to be exchanged between the product and its environment, manufacturer, operator/user, and other products and systems. Connectivity also enables some capabilities of the product to exist outside the physical device, in what is known as the product cloud. The data collected from these products can be then analyzed to inform decision-making, enable operational efficiencies and continuously improve the performance of the product.

Custom-fit means personalized with regard to shape and size. A customized product would imply the modification of some of its characteristics according to the customers requirements such as with a custom car. However, when fit is added to the term, customization could give the idea of both the geometric characteristics of the body and the individual customer requirements, e.g., the steering wheel of the Formula 1 driver Fernando Alonso.

Digital Geometric Kernel, is a software development framework and a set of components for enabling 3D/CAD functionality in Windows applications, developed by DInsight.

Cloud-based design and manufacturing (CBDM) refers to a service-oriented networked product development model in which service consumers are able to configure products or services and reconfigure manufacturing systems through Infrastructure-as-a-Service (IaaS), Platform-as-a-Service (PaaS), Hardware-as-a-Service (HaaS), and Software-as-a-Service (SaaS). Adapted from the original cloud computing paradigm and introduced into the realm of computer-aided product development, Cloud-Based Design and Manufacturing is gaining significant momentum and attention from both academia and industry.

A four-dimensional product considers a physical product as a life-like entity capable of changing form and physical properties autonomously over time. It is an evolving field of product design practice and research linked to similar concepts at the material scale, however, typically utilizes sensors and actuators in order to respond to environmental and human conditions, modifying the shape, color, character and other physical properties of the product. In this way 4D products share similarities with responsive architecture, at the more human scale associated with products.