A rotary dial is a component of a telephone or a telephone switchboard that implements a signaling technology in telecommunications known as pulse dialing. It is used when initiating a telephone call to transmit the destination telephone number to a telephone exchange.

A potentiometer is a three-terminal resistor with a sliding or rotating contact that forms an adjustable voltage divider. If only two terminals are used, one end and the wiper, it acts as a variable resistor or rheostat.

A Hall effect sensor is any sensor incorporating one or more Hall elements, each of which produces a voltage proportional to one axial component of the magnetic field vector B using the Hall effect.

An actuator is a component of a machine that produces force, torque, or displacement, when an electrical, pneumatic or hydraulic input is supplied to it in a system. The effect is usually produced in a controlled way. An actuator translates such an input signal into the required form of mechanical energy. It is a type of transducer. In simple terms, it is a "mover".

A contact breaker is a type of electrical switch, found in the ignition systems of spark-ignition internal combustion engines. The switch is automatically operated by a cam driven by the engine. The timing of operation of the switch is set so that a spark is produced at the right time to ignite the compressed air/fuel mixture in the cylinder of the engine. A mechanism may be provided to slightly adjust timing to allow for varying load on the engine. Since these contacts operate frequently, they are subject to wear, causing erratic ignition of the engine. More recent engines use electronic means to trigger the spark, which eliminated contact wear and allows computer control of ignition timing.

The linear variable differential transformer (LVDT) – also called linear variable displacement transformer, linear variable displacement transducer, or simply differential transformer – is a type of electrical transformer used for measuring linear displacement. A counterpart to this device that is used for measuring rotary displacement is called a rotary variable differential transformer (RVDT).

A resolver is a type of rotary electrical transformer used for measuring degrees of rotation. It is considered an analog device, and has digital counterparts such as the digital resolver, rotary encoder.

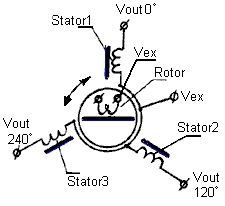

A synchro is, in effect, a transformer whose primary-to-secondary coupling may be varied by physically changing the relative orientation of the two windings. Synchros are often used for measuring the angle of a rotating machine such as an antenna platform or transmitting rotation. In its general physical construction, it is much like an electric motor. The primary winding of the transformer, fixed to the rotor, is excited by an alternating current, which by electromagnetic induction causes voltages to appear between the Y-connected secondary windings fixed at 120 degrees to each other on the stator. The voltages are measured and used to determine the angle of the rotor relative to the stator.

A slip ring is an electromechanical device that allows the transmission of power and electrical signals from a stationary to a rotating structure. A slip ring can be used in any electromechanical system that requires rotation while transmitting power or signals. It can improve mechanical performance, simplify system operation and eliminate damage-prone wires dangling from movable joints.

In electrical engineering, a stepping switch or stepping relay, also known as a uniselector, is an electromechanical device that switches an input signal path to one of several possible output paths, directed by a train of electrical pulses.

A paddle is a game controller with a round wheel and one or more fire buttons, where the wheel is typically used to control movement of the player object along one axis of the video screen. A paddle controller rotates through a fixed arc ; it has a stop at each end.

In various contexts of science, technology, and manufacturing, an indicator is any of various instruments used to accurately measure small distances and angles, and amplify them to make them more obvious. The name comes from the concept of indicating to the user that which their naked eye cannot discern; such as the presence, or exact quantity, of some small distance.

A wheel speed sensor (WSS) or vehicle speed sensor (VSS) is a type of tachometer. It is a sender device used for reading the speed of a vehicle's wheel rotation. It usually consists of a toothed ring and pickup.

A servomotor is a rotary or linear actuator that allows for precise control of angular or linear position, velocity, and acceleration in a mechanical system. It constitutes part of a servomechanism, and consists of a suitable motor coupled to a sensor for position feedback and a controller.

A linear encoder is a sensor, transducer or readhead paired with a scale that encodes position. The sensor reads the scale in order to convert the encoded position into an analog or digital signal, which can then be decoded into position by a digital readout (DRO) or motion controller.

An optical chopper is a device which periodically interrupts a light beam. Three types are available: variable frequency rotating disc choppers, fixed frequency tuning fork choppers, and optical shutters. A rotating disc chopper was famously used in 1849 by Hippolyte Fizeau in the first non-astronomical measurement of the speed of light.

A detent is a mechanical or magnetic means to resist or arrest the movement of a mechanical device. Such a device can be anything ranging from a simple metal pin to a machine. The term is also used for the method involved.

In computing, an input device is a piece of equipment used to provide data and control signals to an information processing system, such as a computer or information appliance. Examples of input devices include keyboards, computer mice, scanners, cameras, joysticks, and microphones.

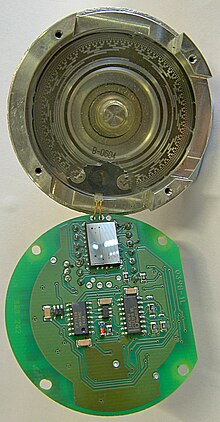

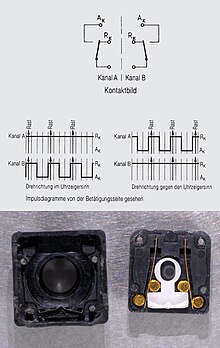

An incremental encoder is a linear or rotary electromechanical device that has two output signals, A and B, which issue pulses when the device is moved. Together, the A and B signals indicate both the occurrence of and direction of movement. Many incremental encoders have an additional output signal, typically designated index or Z, which indicates the encoder is located at a particular reference position. Also, some encoders provide a status output that indicates internal fault conditions such as a bearing failure or sensor malfunction.

FRABA is a worldwide company founded in Germany. The company manufactures products for fabrication and process automation and is specialized in sensor manufacturing, for example sensors which are used in windmills and heavy machinery. The company holds several patents of encoder innovation. Until the 1960s, FRABA's main product was mechanical relays. In 1963 the company started selling brush rotary encoders, leading to the development of the first optical rotary encoder in 1973 and the magneticmulti-turnn rotary encoder in 2007.