This article needs additional citations for verification .(August 2015) |

A scratch drive actuator (SDA) is a microelectromechanical system device that converts electrical energy into one-dimensional motion. [1] [2]

This article needs additional citations for verification .(August 2015) |

A scratch drive actuator (SDA) is a microelectromechanical system device that converts electrical energy into one-dimensional motion. [1] [2]

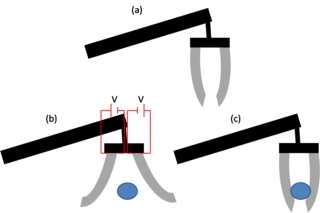

The actuator component can come in many shapes and sizes, depending on the fabrication method used. It can be visualised as an 'L'. The smaller end is called the 'bushing'.

The actuator sits on top of a substrate that has a thin insulating dielectric layer on top. A voltage is applied between the actuator and the substrate, and the resulting potential pulls the body of the actuator downwards. When this occurs, the brush is pushed forwards by a small amount, and energy is stored in the strained actuator. When the voltage is removed, the actuator springs back into shape while the bushing remains in its new position. By applying a pulsed voltage, the SDA can be made to move forward.

The voltage is usually applied to the actuator by means of a 'tether'. This can consist of a rigid connector or a rail which the SDA follows. [3]

The size of an SDA is typically measured on the μm scale.

An actuator is a component of a machine that produces force, torque, or displacement, usually in a controlled way, when an electrical, pneumatic or hydraulic input is supplied to it in a system. An actuator converts such an input signal into the required form of mechanical energy. It is a type of transducer. In simple terms, it is a "mover".

A surface acoustic wave (SAW) is an acoustic wave traveling along the surface of a material exhibiting elasticity, with an amplitude that typically decays exponentially with depth into the material, such that they are confined to a depth of about one wavelength.

A synchronous electric motor is an AC electric motor in which, at steady state, the rotation of the shaft is synchronized with the frequency of the supply current; the rotation period is exactly equal to an integer number of AC cycles. Synchronous motors use electromagnets as the stator of the motor which create a magnetic field that rotates in time with the oscillations of the current. The rotor with permanent magnets or electromagnets turns in step with the stator field at the same rate and as a result, provides the second synchronized rotating magnet field. A synchronous motor is termed doubly fed if it is supplied with independently excited multiphase AC electromagnets on both the rotor and stator.

Energy harvesting (EH) – also known as power harvesting,energy scavenging, or ambient power – is the process by which energy is derived from external sources, then stored for use by small, wireless autonomous devices, like those used in wearable electronics, condition monitoring, and wireless sensor networks.

An electroactive polymer (EAP) is a polymer that exhibits a change in size or shape when stimulated by an electric field. The most common applications of this type of material are in actuators and sensors. A typical characteristic property of an EAP is that they will undergo a large amount of deformation while sustaining large forces.

A piezoelectric motor or piezo motor is a type of electric motor based on the change in shape of a piezoelectric material when an electric field is applied, as a consequence of the converse piezoelectric effect. An electrical circuit makes acoustic or ultrasonic vibrations in the piezoelectric material, most often lead zirconate titanate and occasionally lithium niobate or other single-crystal materials, which can produce linear or rotary motion depending on their mechanism. Examples of types of piezoelectric motors include inchworm motors, stepper and slip-stick motors as well as ultrasonic motors which can be further categorized into standing wave and travelling wave motors. Piezoelectric motors typically use a cyclic stepping motion, which allows the oscillation of the crystals to produce an arbitrarily large motion, as opposed to most other piezoelectric actuators where the range of motion is limited by the static strain that may be induced in the piezoelectric element.

Comb-drives are microelectromechanical actuators, often used as linear actuators, which utilize electrostatic forces that act between two electrically conductive combs. Comb drive actuators typically operate at the micro- or nanometer scale and are generally manufactured by bulk micromachining or surface micromachining a silicon wafer substrate.

A MEMS thermal actuator is a microelectromechanical device that typically generates motion by thermal expansion amplification. A small amount of thermal expansion of one part of the device translates to a large amount of deflection of the overall device. Usually fabricated out of doped single crystal silicon or polysilicon as a complex compliant member, the increase in temperature can be achieved internally by electrical resistive heating or by a heat source capable of locally introducing heat. Microfabricated thermal actuators can be integrated into micromotors.

Dielectric elastomers (DEs) are smart material systems that produce large strains and are promising for Soft robotics, Artificial muscle, etc. They belong to the group of electroactive polymers (EAP). DE actuators (DEA) transform electric energy into mechanical work and vice versa. Thus, they can be used as both actuators, sensors, and energy-harvesting devices. They have high elastic energy density and fast response due to being lightweight, highly stretchable, and operating under the electrostatic principle. They have been investigated since the late 1990s. Many prototype applications exist. Every year, conferences are held in the US and Europe.

Patterned media is a potential future hard disk drive technology to record data in magnetic islands, as opposed to current hard disk drive technology where each bit is stored in 20–30 magnetic grains within a continuous magnetic film. The islands would be patterned from a precursor magnetic film using nanolithography. It is one of the proposed technologies to succeed perpendicular recording due to the greater storage densities it would enable. BPM was introduced by Toshiba in 2010.

Micropumps are devices that can control and manipulate small fluid volumes. Although any kind of small pump is often referred to as a micropump, a more accurate definition restricts this term to pumps with functional dimensions in the micrometer range. Such pumps are of special interest in microfluidic research, and have become available for industrial product integration in recent years. Their miniaturized overall size, potential cost and improved dosing accuracy compared to existing miniature pumps fuel the growing interest for this innovative kind of pump.

A device generating linear or rotational motion using carbon nanotube(s) as the primary component, is termed a nanotube nanomotor. Nature already has some of the most efficient and powerful kinds of nanomotors. Some of these natural biological nanomotors have been re-engineered to serve desired purposes. However, such biological nanomotors are designed to work in specific environmental conditions. Laboratory-made nanotube nanomotors on the other hand are significantly more robust and can operate in diverse environments including varied frequency, temperature, mediums and chemical environments. The vast differences in the dominant forces and criteria between macroscale and micro/nanoscale offer new avenues to construct tailor-made nanomotors. The various beneficial properties of carbon nanotubes makes them the most attractive material to base such nanomotors on.

A plasmonic-enhanced solar cell, commonly referred to simply as plasmonic solar cell, is a type of solar cell that converts light into electricity with the assistance of plasmons, but where the photovoltaic effect occurs in another material.

Co-fired ceramic devices are monolithic, ceramic microelectronic devices where the entire ceramic support structure and any conductive, resistive, and dielectric materials are fired in a kiln at the same time. Typical devices include capacitors, inductors, resistors, transformers, and hybrid circuits. The technology is also used for robust assembly and packaging of electronic components multi-layer packaging in the electronics industry, such as military electronics, MEMS, microprocessor and RF applications.

Optoelectrowetting (OEW) is a method of liquid droplet manipulation used in microfluidics applications. This technique builds on the principle of electrowetting, which has proven useful in liquid actuation due to fast switching response times and low power consumption. Where traditional electrowetting runs into challenges, however, such as in the simultaneous manipulation of multiple droplets, OEW presents a lucrative alternative that is both simpler and cheaper to produce. OEW surfaces are easy to fabricate, since they require no lithography, and have real-time, reconfigurable, large-scale manipulation control, due to its reaction to light intensity.

Inkjet technology originally was invented for depositing aqueous inks on paper in 'selective' positions based on the ink properties only. Inkjet nozzles and inks were designed together and the inkjet performance was based on a design. It was used as a data recorder in the early 1950s, later in the 1950s co-solvent-based inks in the publishing industry were seen for text and images, then solvent-based inks appeared in industrial marking on specialized surfaces and in the1990's phase change or hot-melt ink has become a popular with images and digital fabrication of electronic and mechanical devices, especially jewelry. Although the terms "jetting", "inkjet technology" and "inkjet printing", are commonly used interchangeably, inkjet printing usually refers to the publishing industry, used for printing graphical content, while industrial jetting usually refers to general purpose fabrication via material particle deposition.

Soft robotics is a subfield of robotics that concerns the design, control, and fabrication of robots composed of compliant materials, instead of rigid links. In contrast to rigid-bodied robots built from metals, ceramics and hard plastics, the compliance of soft robots can improve their safety when working in close contact with humans.

Liquid crystal elastomers (LCEs) are slightly crosslinked liquid crystalline polymer networks. These materials combine the entropy elasticity of an elastomer with the self-organization of the liquid crystalline phase. In liquid crystalline elastomers, the mesogens can either be part of the polymer chain or are attached via an alkyl spacer.

A microvalve is a microscale valve, i.e. a microfluidic two-port component that regulates the flow between two fluidic ports. Microvalves are basic components in microfluidic devices, such as labs-on-a-chip, where they are used to control the fluidic transport. During the period from 1995 to 2005, many microelectromechanical systems-based microvalves were developed.

Vapor etching refers to a process used in the fabrication of Microelectromechanical systems (MEMS) and Nanoelectromechanical systems (NEMS). Sacrificial layers are isotropically etched using gaseous acids such as Hydrogen fluoride and Xenon difluoride to release the free standing components of the device.