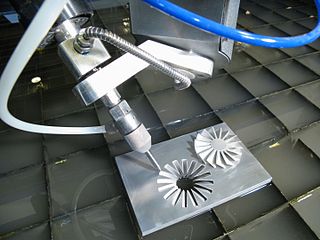

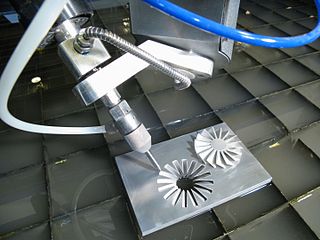

Computer-aided manufacturing (CAM) also known as computer-aided modeling or computer-aided machining is the use of software to control machine tools in the manufacturing of work pieces. This is not the only definition for CAM, but it is the most common. It may also refer to the use of a computer to assist in all operations of a manufacturing plant, including planning, management, transportation and storage. Its primary purpose is to create a faster production process and components and tooling with more precise dimensions and material consistency, which in some cases, uses only the required amount of raw material, while simultaneously reducing energy consumption. CAM is now a system used in schools and lower educational purposes. CAM is a subsequent computer-aided process after computer-aided design (CAD) and sometimes computer-aided engineering (CAE), as the model generated in CAD and verified in CAE can be input into CAM software, which then controls the machine tool. CAM is used in many schools alongside CAD to create objects.

Autodesk, Inc. is an American multinational software corporation that provides software products and services for the architecture, engineering, construction, manufacturing, media, education, and entertainment industries. Autodesk is headquartered in San Francisco, California, and has offices worldwide. Its U.S. offices are located in the states of California, Oregon, Colorado, Texas, Michigan, New Hampshire and Massachusetts. Its Canada offices are located in the provinces of Ontario, Quebec, and Alberta.

In industry, product lifecycle management (PLM) is the process of managing the entire lifecycle of a product from its inception through the engineering, design and manufacture, as well as the service and disposal of manufactured products. PLM integrates people, data, processes, and business systems and provides a product information backbone for companies and their extended enterprises.

PTC Inc. is a computer software and services company founded in 1985 and headquartered in Boston, Massachusetts. The company was a pioneer in parametric, associative feature-based, solid computer-aided design (CAD) modeling software in 1988, including an Internet-based product for Product Lifecycle Management (PLM) in 1998. PTC markets products and services and an Internet of Things (IoT) and augmented reality (AR) platform for partners and developers.

Tebis is a CAD/CAM software provided by Tebis AG, with headquarters in Martinsried near Munich/Germany. Development locations: Martinsried and Norderstedt, Germany International locations: China, Spain, France, Italy, Portugal, Sweden, United Kingdom, USA.

Manufacturing process management (MPM) is a collection of technologies and methods used to define how products are to be manufactured. MPM differs from ERP/MRP which is used to plan the ordering of materials and other resources, set manufacturing schedules, and compile cost data.

Nobel Biocare is a Swiss company originally founded in Sweden for manufacturing dental implants. It is now headquartered in Kloten, Switzerland near the Zürich Airport. Nobel Biocare in its current form was founded in 2002. It originates from a partnership formed in 1978 between Swedish medical researcher Professor Per-Ingvar Brånemark and Bofors, a Swedish company, to industrialize Brånemark's discovery of osseointegration. Beside dental implants, it also presently develops and commercializes CAD/CAM-based prosthetics equipments to scan teeth and to fabricate individualized dental prosthesis using digital technologies in place of silicone molding.

Delcam is a supplier of advanced CAD/CAM software for the manufacturing industry. The company has grown steadily since being founded formally in 1977, after initial development work at Cambridge University, UK. It is now a global developer of product design and manufacturing software, with subsidiaries and joint ventures in North America, South America, Europe and Asia with a total staff of over 800 people and local support provided from over 300 re-seller offices worldwide. It was listed on the London Stock Exchange until 6 February 2014, when it was acquired by Autodesk. It now operates as a wholly owned, independently operated subsidiary of Autodesk.

ISO 13399 is an international technical standard by ISO for the computer-interpretable representation and exchange of industrial product data about cutting tools and toolholders. The objective is to provide a mechanism capable of describing product data regarding cutting tools, independent from any particular system. The nature of this description makes it suitable not only for neutral file exchange, but also as a basis for implementing and sharing product databases and archiving, regarding chttps://en.wikipedia.org/w/index.php?title=ISO_13399&action=editutting tools.

Vero Software is a company based in Cheltenham, England, that specialises in CAD CAM.

Surfware, Inc. is a Camarillo, CA-based company involved in the development of CAD/CAM software.

STEP-NC is a machine tool control language that extends the ISO 10303 STEP standards with the machining model in ISO 14649, adding geometric dimension and tolerance data for inspection, and the STEP PDM model for integration into the wider enterprise. The combined result has been standardized as ISO 10303-238.

Cimatron is an Israeli software company that produces CAD/CAM software for manufacturing, toolmaking and CNC programming applications.

Multiaxis machining is a manufacturing process that involves tools that move in 4 or more directions and are used to manufacture parts out of metal or other materials by milling away excess material, by water jet cutting or by laser cutting. This type of machining was originally performed mechanically on large complex machines. These machines operated on 4, 5, 6, and even 12 axes which were controlled individually via levers that rested on cam plates. The cam plates offered the ability to control the tooling device, the table in which the part is secured, as well as rotating the tooling or part within the machine. Due to the machines size and complexity it took extensive amounts of time to set them up for production. Once computer numerically controlled machining was introduced it provided a faster, more efficient method for machining complex parts.

WorkPLAN is a range of Enterprise Resource Planning (ERP) software products developed by Sescoi for custom manufacturers or departments who work project-based and need specialized ERP software for project management.

WorkNC is a computer-aided manufacturing (CAM) software developed by Sescoi for multi-axis machining.

PartXplore is a computer-aided design (CAD) file viewer developed by Sescoi for reading, analysing, and sharing 3D and 2D CAD files. It was introduced in 2008 and is supported by local Vero offices. The software is available as a viewer and an evaluation version.

Siemens Digital Industries Software is an American computer software company specializing in 3D & 2D Product Lifecycle Management (PLM) software. The company is a business unit of Siemens, operates under the legal name of Siemens Industry Software Inc, and is headquartered in Plano, Texas.

Onshape is a computer-aided design (CAD) software system, delivered over the Internet via a software as a service (SaaS) model. It makes extensive use of cloud computing, with compute-intensive processing and rendering performed on Internet-based servers, and users are able to interact with the system via a web browser or the iOS and Android apps. As a SaaS system, Onshape upgrades are released directly to the web interface, and the software does not require maintenance by the user.