Related Research Articles

A forge is a type of hearth used for heating metals, or the workplace (smithy) where such a hearth is located. The forge is used by the smith to heat a piece of metal to a temperature at which it becomes easier to shape by forging, or to the point at which work hardening no longer occurs. The metal is transported to and from the forge using tongs, which are also used to hold the workpiece on the smithy's anvil while the smith works it with a hammer. Sometimes, such as when hardening steel or cooling the work so that it may be handled with bare hands, the workpiece is transported to the slack tub, which rapidly cools the workpiece in a large body of water. However, depending on the metal type, it may require an oil quench or a salt brine instead; many metals require more than plain water hardening. The slack tub also provides water to control the fire in the forge.

A hammer is a tool, most often a hand tool, consisting of a weighted "head" fixed to a long handle that is swung to deliver an impact to a small area of an object. This can be, for example, to drive nails into wood, to shape metal, or to crush rock. Hammers are used for a wide range of driving, shaping, breaking and non-destructive striking applications. Traditional disciplines include carpentry, blacksmithing, warfare, and percussive musicianship.

A chisel is a tool with a characteristically shaped cutting edge of blade on its end, for carving or cutting a hard material such as wood, stone, or metal by hand, struck with a mallet, or mechanical power. The handle and blade of some types of chisel are made of metal or of wood with a sharp edge in it.

A blacksmith is a metalsmith who creates objects primarily from wrought iron or steel, but sometimes from other metals, by forging the metal, using tools to hammer, bend, and cut. Blacksmiths produce objects such as gates, grilles, railings, light fixtures, furniture, sculpture, tools, agricultural implements, decorative and religious items, cooking utensils, and weapons. There was an historical distinction between the heavy work of the blacksmith and the more delicate operation of a whitesmith, who usually worked in gold, silver, pewter, or the finishing steps of fine steel. The place where a blacksmith works is called variously a smithy, a forge or a blacksmith's shop.

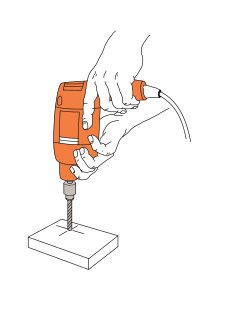

A drill is a tool used for making round holes or driving fasteners. It is fitted with a bit, either a drill or driverchuck. with hand-operated types dramatically decreasing in popularity and cordless battery-powered ones proliferating.

An anvil is a metalworking tool consisting of a large block of metal, with a flattened top surface, upon which another object is struck.

A splitting maul also known as a block buster, block splitter, chop and maul, sledge axe, go-devil or hamaxe is a heavy, long-handled axe used for splitting a piece of wood along its grain. One side of its head is like a sledgehammer, and the other side is like an axe.

A mallet is a tool used for imparting force on another object, often made of rubber or sometimes wood, that is smaller than a maul or beetle, and usually has a relatively large head. The term is descriptive of the overall size and proportions of the tool, and not the materials it may be made of, though most mallets have striking faces that are softer than steel.

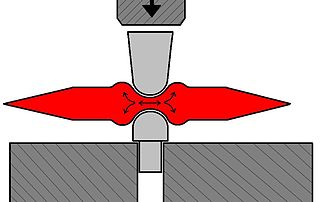

A fuller is a rounded or beveled longitudinal groove or slot along the flat side of a blade that is made using a blacksmithing tool called a spring swage or, like the groove, a fuller. A fuller is often used to widen a blade. When combined with proper distal tapers, heat treatment and blade tempering, a fullered blade can be 20% to 35% lighter than a non-fullered blade with minimal sacrifice of strength or blade integrity. This effect lessens as the blade is reduced in length. A blade is said to be "fullered" after introduction of the groove.

A sledgehammer is a tool with a large, flat, often metal head, attached to a long handle. The long handle combined with a heavy head allows the sledgehammer to gather momentum during a swing and apply a large force compared to hammers designed to drive nails. Along with the mallet, it shares the ability to distribute force over a wide area. This is in contrast to other types of hammers, which concentrate force in a relatively small area.

A ball-peen or ball peinhammer, also known as a machinist's hammer, is a type of peening hammer used in metalworking. It has two heads, one flat and the other, called the peen, rounded. It is distinguished from a cross-peen hammer, diagonal-peen hammer, point-peen hammer, or chisel-peen hammer by having a hemispherical peen.

Hardy tools, also known as anvil tools or bottom tools, are metalworking tools used in anvils. A hardy has a square shank, which prevents it from rotating when placed in the anvil's hardy hole. The term "hardy", used alone, refers to a hot cutting chisel used in the square hole of the anvil. Other bottom tools are identified by function. Typical hardy tools include chisels and bending drifts. They are generally used with a matching top tool.

A saw set is a tool or part of the tool kit for tuning saw blades. It adjusts the set, or distance the saw tooth is bent away from the saw blade. The magnitude of set determines the cut width and prevents the blade of the saw from binding in the wood.

In metalworking, a fuller is a tool used to form metal when hot. The fuller has a rounded, either cylindrical or parabolic, nose, and may either have a handle or a shank. The shank of the lower fuller allows the fuller to be inserted into the hardy hole of the anvil. Upper fullers furthermore come in "straight" or "cross" varieties, depending on the orientation of the handle relative to the face.

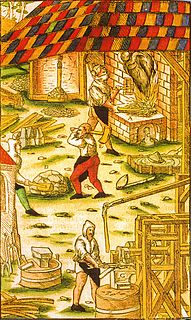

A hammer mill, hammer forge or hammer works was a workshop in the pre-industrial era that was typically used to manufacture semi-finished, wrought iron products or, sometimes, finished agricultural or mining tools, or military weapons. The feature that gave its name to these workshops was the water-driven trip hammer, or set of hammers, used in the process. The shaft, or 'helve', of the hammer was pivoted in the middle and the hammer head was lifted by the action of cams set on a rotating camshaft that periodically depressed the end of the shaft. As it rose and fell, the head of the hammer described an arc. The face of the hammer was made of iron for durability.

An impact wrench is a socket wrench power tool designed to deliver high torque output with minimal exertion by the user, by storing energy in a rotating mass, then delivering it suddenly to the output shaft. It was invented by Robert H. Pott of Evansville, Indiana.

A meat tenderizer, or meat pounder is a hand-powered tool used to tenderize slabs of meat in the preparation for cooking. Although a meat tenderizer can be made out of virtually any object, there are three types manufactured specifically for tenderizing meat.

A cat's paw or cat's claw is a standard carpenter's tool, consisting of a round, hexagonal, or flat bar that curves at one end to form a pointed, cup-shaped tip with a V-shaped cleft for gripping nailheads. Popular retail outlets currently call these a claw bar if it has a claw on each end, or a moulding bar if it has a claw on one end and a flat pry bar on the other. It essentially works as a small crowbar. To use the tool the user holds the tool's shank with one hand and drives the claw around a nailhead with a hammer. When the V is firmly seated around the nail's shank, the users pull the bar back to raise the head, then finishes pulling the nail with the hammer's claw. The cat's paw is well designed for demolition work, but because it tears up the wood around the nailhead, it should not be used for finish work.

An axe is an implement that has been used for millennia to shape, split and cut wood, to harvest timber, as a weapon, and as a ceremonial or heraldic symbol. The axe has many forms and specialised uses but generally consists of an axe head with a handle, or helve.

Vaughan & Bushnell Manufacturing, also known as Vaughan Manufacturing and branded as simply Vaughan, is an American manufacturing company that specializes in the production of hammers, axes, prybars, and hand saws. The company produces more than 250 different kinds of hammers.

References

- ↑ McRaven, Charles (2005), The blacksmith's craft (2nd ed.), Storey Publishinglifr, p. 31, ISBN 978-1-58017-593-7.