Rheology is the study of the flow of matter, primarily in a fluid state but also as "soft solids" or solids under conditions in which they respond with plastic flow rather than deforming elastically in response to an applied force. Rheology is the branch of physics that deals with the deformation and flow of materials, both solids and liquids.

A viscometer is an instrument used to measure the viscosity of a fluid. For liquids with viscosities which vary with flow conditions, an instrument called a rheometer is used. Thus, a rheometer can be considered as a special type of viscometer. Viscometers can measure only constant viscosity, that is, viscosity that does not change with flow conditions.

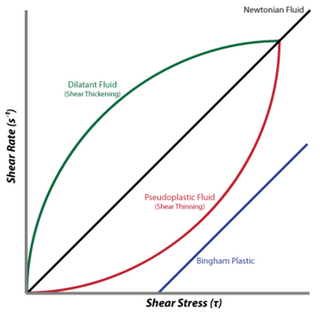

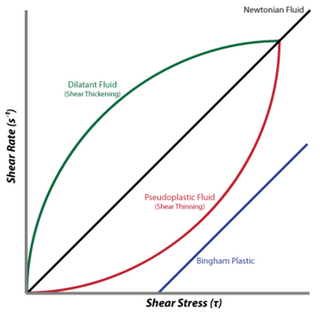

A non-Newtonian fluid is a fluid that does not follow Newton's law of viscosity, that is, it has variable viscosity dependent on stress. In particular, the viscosity of non-Newtonian fluids can change when subjected to force. Ketchup, for example, becomes runnier when shaken and is thus a non-Newtonian fluid. Many salt solutions and molten polymers are non-Newtonian fluids, as are many commonly found substances such as custard, toothpaste, starch suspensions, corn starch, paint, blood, melted butter, and shampoo.

A Newtonian fluid is a fluid in which the viscous stresses arising from its flow are at every point linearly correlated to the local strain rate — the rate of change of its deformation over time. Stresses are proportional to the rate of change of the fluid's velocity vector.

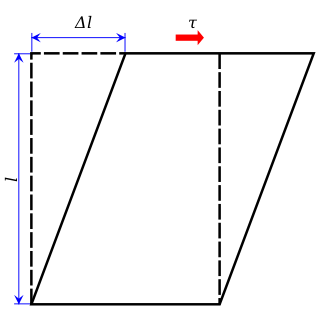

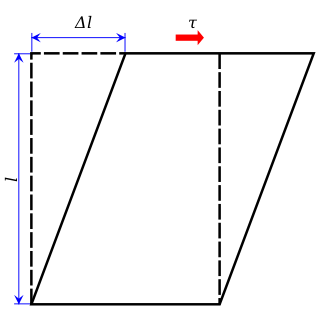

Shear stress is the component of stress coplanar with a material cross section. It arises from the shear force, the component of force vector parallel to the material cross section. Normal stress, on the other hand, arises from the force vector component perpendicular to the material cross section on which it acts.

In continuum mechanics, a power-law fluid, or the Ostwald–de Waele relationship, is a type of generalized Newtonian fluid for which the shear stress, τ, is given by

Hemorheology, also spelled haemorheology, or blood rheology, is the study of flow properties of blood and its elements of plasma and cells. Proper tissue perfusion can occur only when blood's rheological properties are within certain levels. Alterations of these properties play significant roles in disease processes. Blood viscosity is determined by plasma viscosity, hematocrit and mechanical properties of red blood cells. Red blood cells have unique mechanical behavior, which can be discussed under the terms erythrocyte deformability and erythrocyte aggregation. Because of that, blood behaves as a non-Newtonian fluid. As such, the viscosity of blood varies with shear rate. Blood becomes less viscous at high shear rates like those experienced with increased flow such as during exercise or in peak-systole. Therefore, blood is a shear-thinning fluid. Contrarily, blood viscosity increases when shear rate goes down with increased vessel diameters or with low flow, such as downstream from an obstruction or in diastole. Blood viscosity also increases with increases in red cell aggregability.

In materials science and continuum mechanics, viscoelasticity is the property of materials that exhibit both viscous and elastic characteristics when undergoing deformation. Viscous materials, like water, resist both shear flow and strain linearly with time when a stress is applied. Elastic materials strain when stretched and immediately return to their original state once the stress is removed.

Thixotropy is a time-dependent shear thinning property. Certain gels or fluids that are thick or viscous under static conditions will flow over time when shaken, agitated, shear-stressed, or otherwise stressed. They then take a fixed time to return to a more viscous state. Some non-Newtonian pseudoplastic fluids show a time-dependent change in viscosity; the longer the fluid undergoes shear stress, the lower its viscosity. A thixotropic fluid is a fluid which takes a finite time to attain equilibrium viscosity when introduced to a steep change in shear rate. Some thixotropic fluids return to a gel state almost instantly, such as ketchup, and are called pseudoplastic fluids. Others such as yogurt take much longer and can become nearly solid. Many gels and colloids are thixotropic materials, exhibiting a stable form at rest but becoming fluid when agitated. Thixotropy arises because particles or structured solutes require time to organize.

A dilatant material is one in which viscosity increases with the rate of shear strain. Such a shear thickening fluid, also known by the initialism STF, is an example of a non-Newtonian fluid. This behaviour is usually not observed in pure materials, but can occur in suspensions.

A generalized Newtonian fluid is an idealized fluid for which the shear stress is a function of shear rate at the particular time, but not dependent upon the history of deformation. Although this type of fluid is non-Newtonian in nature, its constitutive equation is a generalised form of the Newtonian fluid. Generalised Newtonian fluids satisfy the following rheological equation:

Rheometry generically refers to the experimental techniques used to determine the rheological properties of materials, that is the qualitative and quantitative relationships between stresses and strains and their derivatives. The techniques used are experimental. Rheometry investigates materials in relatively simple flows like steady shear flow, small amplitude oscillatory shear, and extensional flow.

The upper-convected Maxwell (UCM) model is a generalisation of the Maxwell material for the case of large deformations using the upper-convected time derivative. The model was proposed by James G. Oldroyd. The concept is named after James Clerk Maxwell.

In fluid mechanics, apparent viscosity is the shear stress applied to a fluid divided by the shear rate:

The Herschel–Bulkley fluid is a generalized model of a non-Newtonian fluid, in which the strain experienced by the fluid is related to the stress in a complicated, non-linear way. Three parameters characterize this relationship: the consistency k, the flow index n, and the yield shear stress . The consistency is a simple constant of proportionality, while the flow index measures the degree to which the fluid is shear-thinning or shear-thickening. Ordinary paint is one example of a shear-thinning fluid, while oobleck provides one realization of a shear-thickening fluid. Finally, the yield stress quantifies the amount of stress that the fluid may experience before it yields and begins to flow.

Rheological weldability (RW) of thermoplastics considers the materials flow characteristics in determining the weldability of the given material. The process of welding thermal plastics requires three general steps, first is surface preparation. The second step is the application of heat and pressure to create intimate contact between the components being joined and initiate inter-molecular diffusion across the joint and the third step is cooling. RW can be used to determine the effectiveness of the second step of the process for given materials.

In continuum mechanics, time-dependent viscosity is a property of fluids whose viscosity changes as a function of time. The most common type of this is thixotropy, in which the viscosity of fluids under continuous shear decreases with time; the opposite is rheopecty, in which viscosity increases with time.

An important class of non-Newtonian fluids presents a yield stress limit which must be exceeded before significant deformation can occur – the so-called viscoplastic fluids or Bingham plastics. In order to model the stress-strain relation in these fluids, some fitting have been proposed such as the linear Bingham equation and the non-linear Herschel-Bulkley and Casson models.

Capillary breakup rheometry is an experimental technique used to assess the extensional rheological response of low viscous fluids. Unlike most shear and extensional rheometers, this technique does not involve active stretch or measurement of stress or strain but exploits only surface tension to create a uniaxial extensional flow. Hence, although it is common practice to use the name rheometer, capillary breakup techniques should be better addressed to as indexers.

Squeeze flow is a type of flow in which a material is pressed out or deformed between two parallel plates or objects. First explored in 1874 by Josef Stefan, squeeze flow describes the outward movement of a droplet of material, its area of contact with the plate surfaces, and the effects of internal and external factors such as temperature, viscoelasticity, and heterogeneity of the material. Several squeeze flow models exist to describe Newtonian and non-Newtonian fluids undergoing squeeze flow under various geometries and conditions. Numerous applications across scientific and engineering disciplines including rheometry, welding engineering, and materials science provide examples of squeeze flow in practical use.

![Shear thinning in a polymeric system: dependence of apparent viscosity on shear rate. e0 is the zero shear rate viscosity and e[?] is the infinite shear viscosity plateau. Shear thinning 2.png](http://upload.wikimedia.org/wikipedia/commons/thumb/f/f4/Shear_thinning_2.png/272px-Shear_thinning_2.png)