Copra is the dried, white flesh of the coconut from which coconut oil is extracted. Traditionally, the coconuts are sun-dried, especially for export, before the oil, also known as copra oil, is pressed out. The oil extracted from copra is rich in lauric acid, making it an important commodity in the preparation of lauryl alcohol, soaps, fatty acids, cosmetics, etc. and thus a lucrative product for many coconut-producing countries. The palatable oil cake, known as copra cake, obtained as a residue in the production of copra oil is used in animal feeds. The ground cake is known as coconut or copra meal.

In passive solar building design, windows, walls, and floors are made to collect, store, reflect, and distribute solar energy, in the form of heat in the winter and reject solar heat in the summer. This is called passive solar design because, unlike active solar heating systems, it does not involve the use of mechanical and electrical devices.

Spray drying is a method of forming a dry powder from a liquid or slurry by rapidly drying with a hot gas. This is the preferred method of drying of many thermally-sensitive materials such as foods and pharmaceuticals, or materials which may require extremely consistent, fine particle size. Air is most commonly used as the heated drying medium; however, nitrogen may be used if the liquid is flammable or if the product is oxygen-sensitive.

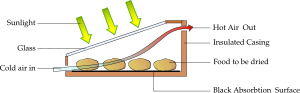

Food drying is a method of food preservation in which food is dried. Drying inhibits the growth of bacteria, yeasts, and mold through the removal of water. Dehydration has been used widely for this purpose since ancient times; the earliest known practice is 12,000 B.C. by inhabitants of the modern Asian and Middle Eastern regions. Water is traditionally removed through evaporation by using methods such as air drying, sun drying, smoking or wind drying, although today electric food dehydrators or freeze-drying can be used to speed the drying process and ensure more consistent results.

Jerky or "charqui" is lean trimmed meat cut into strips and dehydrated to prevent spoilage. Normally, this drying includes the addition of salt to prevent bacteria growth. The word "jerky" derives from the Quechua word ch'arki which means "dried, salted meat".

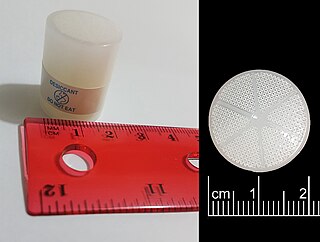

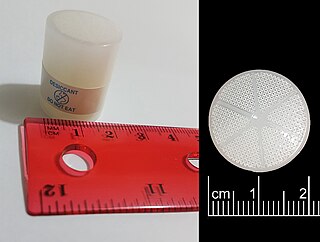

Silica gel is an amorphous and porous form of silicon dioxide (silica), consisting of an irregular tridimensional framework of alternating silicon and oxygen atoms with nanometer-scale voids and pores. The voids may contain water or some other liquids, or may be filled by gas or vacuum. In the last case, the material is properly called silica xerogel.

A desiccant is a hygroscopic substance that is used to induce or sustain a state of dryness (desiccation) in its vicinity; it is the opposite of a humectant. Commonly encountered pre-packaged desiccants are solids that absorb water. Desiccants for specialized purposes may be in forms other than solid, and may work through other principles, such as chemical bonding of water molecules. They are commonly encountered in foods to retain crispness. Industrially, desiccants are widely used to control the level of water in gas streams.

A clothes dryer is a powered household appliance that is used to remove moisture from a load of clothing, bedding and other textiles, usually after they are washed in the washing machine.

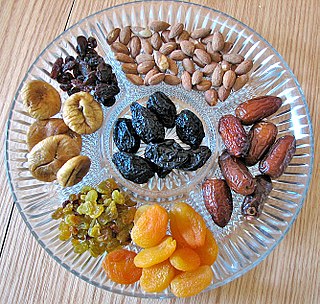

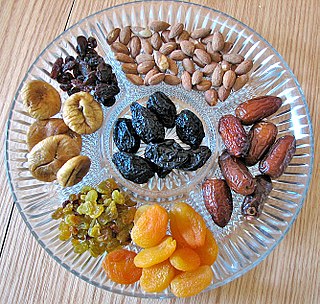

Dried fruit is fruit from which the majority of the original water content has been removed prior to cooking or being eaten on its own. Drying may occur either naturally, by sun, through the use of industrial dehydrators, or by freeze drying. Dried fruit has a long tradition of use dating to the fourth millennium BC in Mesopotamia, and is valued for its sweet taste, nutritional content, and long shelf life.

A clothes line, also spelled clothesline, also known as a wash line, is a device for hanging clothes on for the purpose of drying or airing out the articles. It is made of any type of rope, cord, wire, or twine that has been stretched between two points, outdoors or indoors, above ground level. Clothing that has recently been washed is hung over the line to dry, held in place using clothes pegs or clothespins. Washing lines are attached either from a post or a wall, and are frequently located in back gardens, or on balconies. Longer washing lines often have props holding up the mid-section so the weight of the clothing does not pull the clothesline down to the ground.

Freeze drying, also known as lyophilization or cryodesiccation, is a low temperature dehydration process that involves freezing the product and lowering pressure, thereby removing the ice by sublimation. This is in contrast to dehydration by most conventional methods that evaporate water using heat.

Dielectric heating, also known as electronic heating, radio frequency heating, and high-frequency heating, is the process in which a radio frequency (RF) alternating electric field, or radio wave or microwave electromagnetic radiation heats a dielectric material. At higher frequencies, this heating is caused by molecular dipole rotation within the dielectric.

Scrubber systems are a diverse group of air pollution control devices that can be used to remove some particulates and/or gases from industrial exhaust streams. An early application of a carbon dioxide scrubber was in the submarine the Ictíneo I, in 1859; a role for which they continue to be used today. Traditionally, the term "scrubber" has referred to pollution control devices that use liquid to wash unwanted pollutants from a gas stream. Recently, the term has also been used to describe systems that inject a dry reagent or slurry into a dirty exhaust stream to "wash out" acid gases. Scrubbers are one of the primary devices that control gaseous emissions, especially acid gases. Scrubbers can also be used for heat recovery from hot gases by flue-gas condensation. They are also used for the high flows in solar, PV, or LED processes.

Drying is a mass transfer process consisting of the removal of water or another solvent by evaporation from a solid, semi-solid or liquid. This process is often used as a final production step before selling or packaging products. To be considered "dried", the final product must be solid, in the form of a continuous sheet, long pieces, particles or powder. A source of heat and an agent to remove the vapor produced by the process are often involved. In bioproducts like food, grains, and pharmaceuticals like vaccines, the solvent to be removed is almost invariably water. Desiccation may be synonymous with drying or considered an extreme form of drying.

A food dehydrator is a device that removes moisture from food to aid in its preservation. Food drying is a method of preserving fruit, vegetables and meats that has been practiced since antiquity.

Solar air heating is a solar thermal technology in which the energy from the sun, insolation, is captured by an absorbing medium and used to heat air. Solar air heating is a renewable energy heating technology used to heat or condition air for buildings or process heat applications. It is typically the most cost-effective out of all the solar technologies, especially in commercial and industrial applications, and it addresses the largest usage of building energy in heating climates, which is space heating and industrial process heating.

Vacuum drying is the mass transfer operation in which the moisture present in a substance, usually a wet solid, is removed by means of creating a vacuum.

Food powder is the most common format of dried solid food material that meets specific quality standards, such as moisture content, particle size, and particular morphology. Common powdery food products include milk powder, tea powder, cocoa powder, coffee powder, soybean flour, wheat flour, and chili powder. Powders are particulate discrete solid particles of size ranging from nanometres to millimetres that generally flow freely when shaken or tilted. The bulk powder properties are the combined effect of particle properties by the conversion of food products in solid state into powdery form for ease of use, processing and keeping quality. Various terms are used to indicate the particulate solids in bulk, such as powder, granules, flour and dust, though all these materials can be treated under powder category. These common terminologies are based on the size or the source of the materials.