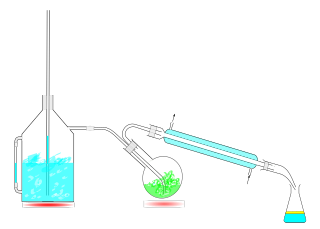

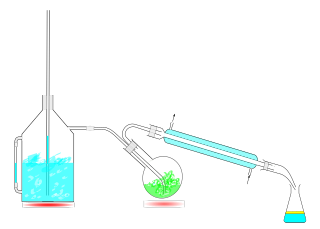

Distillation is the process of separating the components or substances from a liquid mixture by using selective boiling and condensation. Distillation may result in essentially complete separation, or it may be a partial separation that increases the concentration of selected components in the mixture. In either case, the process exploits differences in the relative volatility of the mixture's components. In industrial chemistry, distillation is a unit operation of practically universal importance, but it is a physical separation process, not a chemical reaction. Distillation can also be used to separate a solution made of two or more liquids or fractions, they are called miscible liquids and they must have different boiling points, for example, ethanol and water or fermented fruit juice. a condenser is used a mixture is heated to just over 80 degrees Celsius the ethanol will evaporate and is condensed. It can be collected in a beaker. The water remains in the flask

Coke is a grey, hard, and porous fuel with a high carbon content and few impurities, made by heating coal or oil in the absence of air—a destructive distillation process. It is an important industrial product, used mainly in iron ore smelting, but also as a fuel in stoves and forges when air pollution is a concern.

Water pollution is the contamination of water bodies, usually as a result of human activities. Water bodies include for example lakes, rivers, oceans, aquifers and groundwater. Water pollution results when contaminants are introduced into the natural environment. For example, releasing inadequately treated wastewater into natural water bodies can lead to degradation of aquatic ecosystems. In turn, this can lead to public health problems for people living downstream. They may use the same polluted river water for drinking or bathing or irrigation. Water pollution is the leading worldwide cause of death and disease, e.g. due to water-borne diseases.

Wastewater treatment is a process used to remove contaminants from wastewater or sewage and convert it into an effluent that can be returned to the water cycle with minimum impact on the environment, or directly reused. The latter is called water reclamation because treated wastewater can be used for other purposes. The treatment process takes place in a wastewater treatment plant (WWTP), often referred to as a Water Resource Recovery Facility (WRRF) or a Sewage Treatment Plant (STP). Pollutants in municipal wastewater are removed or broken down.

Vacuum distillation is distillation performed under reduced pressure, which allows the purification of compounds not readily distilled at ambient pressures or simply to save time or energy. This technique separates compounds based on differences in boiling points. This technique is used when the boiling point of the desired compound is difficult to achieve or will cause the compound to decompose. A reduced pressure decreases the boiling point of compounds. The reduction in boiling point can be calculated using a temperature-pressure nomograph using the Clausius–Clapeyron relation.

Biofiltration is a pollution control technique using a bioreactor containing living material to capture and biologically degrade pollutants. Common uses include processing waste water, capturing harmful chemicals or silt from surface runoff, and microbiotic oxidation of contaminants in air.

Steam distillation is a separation process which consists in distilling water together with other volatile and non-volatile components. The steam from the boiling water carries the vapor of the volatiles to a condenser, where both are cooled and return to the liquid or solid state; while the non-volatile residues remain behind in the boiling container.

Petroleum ether is the petroleum fraction consisting of aliphatic hydrocarbons and boiling in the range 35‒60 °C, and commonly used as a laboratory solvent. Despite the name, petroleum ether is not classified as an ether; the term is used only figuratively, signifying extreme lightness and volatility.

Industrial wastewater treatment describes the processes used for treating wastewater that is produced by industries as an undesirable by-product. After treatment, the treated industrial wastewater may be reused or released to a sanitary sewer or to a surface water in the environment.

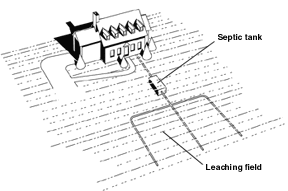

Septic drain fields, also called leach fields or leach drains, are subsurface wastewater disposal facilities used to remove contaminants and impurities from the liquid that emerges after anaerobic digestion in a septic tank. Organic materials in the liquid are catabolized by a microbial ecosystem.

New Source Performance Standards (NSPS) are pollution control standards issued by the United States Environmental Protection Agency (EPA). The term is used in the Clean Air Act Extension of 1970 (CAA) to refer to air pollution emission standards, and in the Clean Water Act (CWA) referring to standards for water pollution discharges of industrial wastewater to surface waters.

Continuous distillation, a form of distillation, is an ongoing separation in which a mixture is continuously fed into the process and separated fractions are removed continuously as output streams. Distillation is the separation or partial separation of a liquid feed mixture into components or fractions by selective boiling and condensation. The process produces at least two output fractions. These fractions include at least one volatile distillate fraction, which has boiled and been separately captured as a vapor condensed to a liquid, and practically always a bottoms fraction, which is the least volatile residue that has not been separately captured as a condensed vapor.

Aqueous Wastes from Petroleum and Petrochemical Plants is a book about the composition and treatment of the various wastewater streams produced in the hydrocarbon processing industries. When it was published in 1967, it was the first book devoted to that subject.

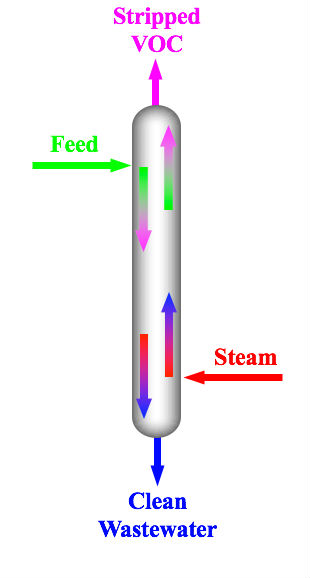

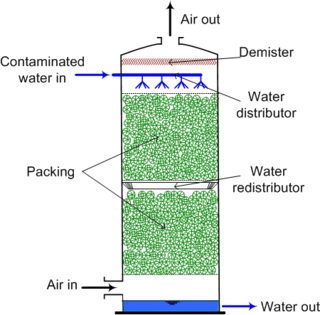

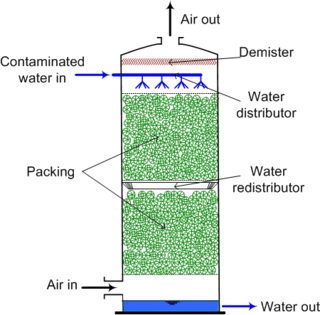

Air stripping is the transferring of volatile components of a liquid into an air stream. It is an environmental engineering technology used for the purification of groundwaters and wastewaters containing volatile compounds.

An API oil–water separator is a device designed to separate gross amounts of oil and suspended solids from the wastewater effluents of oil refineries, petrochemical plants, chemical plants, natural gas processing plants and other industrial oily water sources. The name is derived from the fact that such separators are designed according to standards published by the American Petroleum Institute (API).

A trickling filter is a type of wastewater treatment system. It consists of a fixed bed of rocks, coke, gravel, slag, polyurethane foam, sphagnum peat moss, ceramic, or plastic media over which sewage or other wastewater flows downward and causes a layer of microbial slime (biofilm) to grow, covering the bed of media. Aerobic conditions are maintained by splashing, diffusion, and either by forced-air flowing through the bed or natural convection of air if the filter medium is porous.

Advanced oxidation processes (abbreviation: AOPs), in a broad sense, are a set of chemical treatment procedures designed to remove organic (and sometimes inorganic) materials in water and wastewater by oxidation through reactions with hydroxyl radicals (·OH). In real-world applications of wastewater treatment, however, this term usually refers more specifically to a subset of such chemical processes that employ ozone (O3), hydrogen peroxide (H2O2) and/or UV light. One such type of process is called in situ chemical oxidation.

Stripping is a physical separation process where one or more components are removed from a liquid stream by a vapor stream. In industrial applications the liquid and vapor streams can have co-current or countercurrent flows. Stripping is usually carried out in either a packed or trayed column.

Electrical resistance heating (ERH) is an intensive in situ environmental remediation method that uses the flow of alternating current electricity to heat soil and groundwater and evaporate contaminants. Electric current is passed through a targeted soil volume between subsurface electrode elements. The resistance to electrical flow that exists in the soil causes the formation of heat; resulting in an increase in temperature until the boiling point of water at depth is reached. After reaching this temperature, further energy input causes a phase change, forming steam and removing volatile contaminants. ERH is typically more cost effective when used for treating contaminant source areas.

Environmental impacts of cleaning products entail the consequences that come as a result of chemical compounds in cleaning products. Cleaning agents can be bioactive with consequences ranging from mild to severe. These cleaning products can contain harmful chemicals that have detrimental impacts on the environment. Developmental and endocrine disruptors have been linked to cleaning agents. In addition, the packaging of these products can also post vast environmental consequences. Green cleaning is an approach to redress or address the problems associated with traditional cleaning agents.