A cement is a binder, a chemical substance used for construction that sets, hardens, and adheres to other materials to bind them together. Cement is seldom used on its own, but rather to bind sand and gravel (aggregate) together. Cement mixed with fine aggregate produces mortar for masonry, or with sand and gravel, produces concrete. Concrete is the most widely used material in existence and is behind only water as the planet's most-consumed resource.

Lignite, often referred to as brown coal, is a soft, brown, combustible sedimentary rock formed from naturally compressed peat. It has a carbon content around 25–35% and is considered the lowest rank of coal due to its relatively low heat content. When removed from the ground, it contains a very high amount of moisture, which partially explains its low carbon content. Lignite is mined all around the world and is used almost exclusively as a fuel for steam-electric power generation.

Anthracite, also known as hard coal and black coal, is a hard, compact variety of coal that has a submetallic lustre. It has the highest carbon content, the fewest impurities, and the highest energy density of all types of coal and is the highest ranking of coals.

Incineration is a waste treatment process that involves the combustion of substances contained in waste materials. Industrial plants for waste incineration are commonly referred to as waste-to-energy facilities. Incineration and other high-temperature waste treatment systems are described as "thermal treatment". Incineration of waste materials converts the waste into ash, flue gas and heat. The ash is mostly formed by the inorganic constituents of the waste and may take the form of solid lumps or particulates carried by the flue gas. The flue gases must be cleaned of gaseous and particulate pollutants before they are dispersed into the atmosphere. In some cases, the heat that is generated by incineration can be used to generate electric power.

Solid fuel refers to various forms of solid material that can be burnt to release energy, providing heat and light through the process of combustion. Solid fuels can be contrasted with liquid fuels and gaseous fuels. Common examples of solid fuels include wood, charcoal, peat, coal, hexamine fuel tablets, dry dung, wood pellets, corn, wheat, rice, rye, and other grains. Solid fuels are extensively used in rocketry as solid propellants. Solid fuels have been used throughout human history to create fire and solid fuel is still in widespread use throughout the world in the present day.

A briquette is a compressed block of coal dust or other combustible biomass material used for fuel and kindling to start a fire. The term derives from the French word brique, meaning brick.

A waste-to-energy plant is a waste management facility that combusts wastes to produce electricity. This type of power plant is sometimes called a trash-to-energy, municipal waste incineration, energy recovery, or resource recovery plant.

Pellet fuels are a type of solid fuel made from compressed organic material. Pellets can be made from any one of five general categories of biomass: industrial waste and co-products, food waste, agricultural residues, energy crops, and untreated lumber. Wood pellets are the most common type of pellet fuel and are generally made from compacted sawdust and related industrial wastes from the milling of lumber, manufacture of wood products and furniture, and construction. Other industrial waste sources include empty fruit bunches, palm kernel shells, coconut shells, and tree tops and branches discarded during logging operations. So-called "black pellets" are made of biomass, refined to resemble hard coal and were developed to be used in existing coal-fired power plants. Pellets are categorized by their heating value, moisture and ash content, and dimensions. They can be used as fuels for power generation, commercial or residential heating, and cooking.

Refuse-derived fuel (RDF) is a fuel produced from various types of waste such as municipal solid waste (MSW), industrial waste or commercial waste.

Waste-to-energy (WtE) or energy-from-waste (EfW) is the process of generating energy in the form of electricity and/or heat from the primary treatment of waste, or the processing of waste into a fuel source. WtE is a form of energy recovery. Most WtE processes generate electricity and/or heat directly through combustion, or produce a combustible fuel commodity, such as methane, methanol, ethanol or synthetic fuels, often derived from the product syngas.

A mechanical biological treatment (MBT) system is a type of waste processing facility that combines a sorting facility with a form of biological treatment such as composting or anaerobic digestion. MBT plants are designed to process mixed household waste as well as commercial and industrial wastes.

Pelletizing is the process of compressing or molding a material into the shape of a pellet. A wide range of different materials are pelletized including chemicals, iron ore, animal compound feed, plastics, waste materials, and more. The process is considered an excellent option for the storage and transport of said materials. The technology is widely used in the powder metallurgy engineering and medicine industries.

Cement kilns are used for the pyroprocessing stage of manufacture of portland and other types of hydraulic cement, in which calcium carbonate reacts with silica-bearing minerals to form a mixture of calcium silicates. Over a billion tonnes of cement are made per year, and cement kilns are the heart of this production process: their capacity usually defines the capacity of the cement plant. As the main energy-consuming and greenhouse-gas–emitting stage of cement manufacture, improvement of kiln efficiency has been the central concern of cement manufacturing technology. Emissions from cement kilns are a major source of greenhouse gas emissions, accounting for around 2.5% of non-natural carbon emissions worldwide.

Tire-derived fuel (TDF) is composed of shredded scrap tires. Tires may be mixed with coal or other fuels, such as wood or chemical wastes, to be burned in concrete kilns, power plants, or paper mills. An EPA test program concluded that, with the exception of zinc emissions, potential emissions from TDF are not expected to be very much different from other conventional fossil fuels, as long as combustion occurs in a well-designed, well-operated and well-maintained combustion device.

Refined coal is the product of the coal-upgrading technology that removes moisture and certain pollutants from lower-rank coals such as sub-bituminous and lignite (brown) coals, raising their calorific values. Coal refining or upgrading technologies are typically pre-combustion treatments and processes that alter the characteristics of coal before it is burned. Pre-combustion coal-upgrading technologies aim to increase efficiency and reduce emissions when coal is burned. Depending on the situation, pre-combustion technology can be used in place of or as a supplement to post-combustion technologies to control emissions from coal-fueled boilers.

Torrefaction of biomass, e.g., wood or grain, is a mild form of pyrolysis at temperatures typically between 200 and 320 °C. Torrefaction changes biomass properties to provide a better fuel quality for combustion and gasification applications. Torrefaction produces a relatively dry product, which reduces or eliminates its potential for organic decomposition. Torrefaction combined with densification creates an energy-dense fuel carrier of 20 to 21 GJ/ton lower heating value (LHV). Torrefaction makes the material undergo Maillard reactions. Torrefied biomass can be used as an energy carrier or as a feedstock used in the production of bio-based fuels and chemicals.

Densified coal is the product of the Coldry Process coal upgrading technology that removes moisture from low-rank coals such as sub-bituminous and lignite/brown coal. The densification process raises the calorific value of low-rank coal to equal or exceed that of many export-grade black coals. Densified coal resulting from the Coldry Process is regarded as a black coal equivalent or replacement for black coal.

Black coal equivalent (BCE) is an export coal product derived from the Coldry Process, a patented coal upgrading technology operated by Environmental Clean Technologies Limited, in Victoria, Australia. The Coldry Process is applied to brown coal (lignite) with a typical moisture content of 60 per cent by weight and transforms the coal into a densified coal product of equal or better calorific value to typical export quality black coal, with less ash and sulfur content. Black coal equivalent derived from brown coal is ostensibly a 'cleaner' burning coal fuel than most black coals.

A coal burner is a mechanical device that burns pulverized coal into a flame in a controlled manner. Coal burners are mainly composed of the pulverized coal machine, the host of combustion machine control system, ignition system, the crater and others.

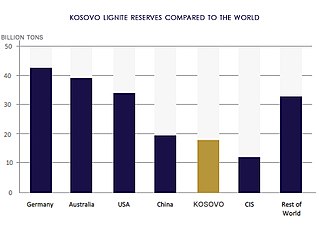

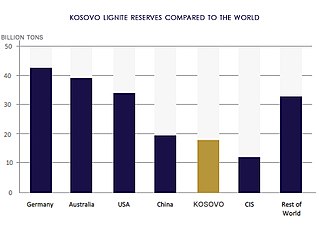

Lignite coal in Kosovo is and will continue to be an important local energy source due to its high reserves. Kosovo is very rich in lignite and accounts around 90% of Kosovo's electricity production. The nation has the 5th largest lignite reserves in the world and the 3rd in Europe. The lignite is distributed across the Kosovo, Dukagjin and Drenica Basins, although mining has so far been restricted to the Kosovo Basin. The lignite is of high quality for the generation of electricity and compares well with the lignite resources of neighbouring countries on a range of parameters. Kosovo's lignite varies in net calorific value from 6.28-9.21 MJ/kg, averaging 7.8 MJ/kg. The deposits can be up to 100 m thick, but average 40 m, and possess an average strip ratio of 1.7:1.