A thermoplastic, or thermosoftening plastic, is any plastic polymer material that becomes pliable or moldable at a certain elevated temperature and solidifies upon cooling.

Polypropylene (PP), also known as polypropene, is a thermoplastic polymer used in a wide variety of applications. It is produced via chain-growth polymerization from the monomer propylene.

A bottle is a narrow-necked container made of an impermeable material in various shapes and sizes that stores and transports liquids. Its mouth, at the bottling line, can be sealed with an internal stopper, an external bottle cap, a closure, or induction sealing.

Polyethylene terephthalate (or poly(ethylene terephthalate), PET, PETE, or the obsolete PETP or PET-P), is the most common thermoplastic polymer resin of the polyester family and is used in fibres for clothing, containers for liquids and foods, and thermoforming for manufacturing, and in combination with glass fibre for engineering resins.

Bottled water is drinking water packaged in plastic or glass water bottles. Bottled water may be carbonated or not, with packaging sizes ranging from small single serving bottles to large carboys for water coolers. The consumption of bottled water is influenced by factors such as convenience, taste, perceived safety, and concerns over the quality of municipal tap water. Concerns about the environmental impact of bottled water, including the production and disposal of plastic bottles, have led to calls for more sustainable practices in the industry.

A bottle cap or bottle top is a closure for the top opening of a bottle. A cap is sometimes colorfully decorated with the logo of the brand of contents. Plastic caps are used for plastic bottles, while metal with plastic backing is used for glass; plastic caps are commonly made from polyethylene or polypropylene, while metal caps are usually either steel or aluminum. Plastic caps may have a pour spout. Flip-Top caps like Flapper closures provide controlled dispensing of dry products. Caps for plastic bottles are often made of a different type of plastic from the bottle.

A drum is a cylindrical shipping container used for shipping bulk cargo. Drums can be made of steel, dense paperboard, or plastic, and are generally used for the transportation and storage of liquids and powders. Drums are often stackable, and have dimensions designed for efficient warehouse and logistics use. This type of packaging is frequently certified for transporting dangerous goods. Proper shipment requires the drum to comply with all applicable regulations.

A keg is a small cask.

High-density polyethylene (HDPE) or polyethylene high-density (PEHD) is a thermoplastic polymer produced from the monomer ethylene. It is sometimes called "alkathene" or "polythene" when used for HDPE pipes. With a high strength-to-density ratio, HDPE is used in the production of plastic bottles, corrosion-resistant piping, geomembranes and plastic lumber. HDPE is commonly recycled, and has the number "2" as its resin identification code.

A water bottle is a container that is used to hold liquids, mainly water, for the purpose of transporting a drink while travelling or while otherwise away from a supply of potable water.

Low-density polyethylene (LDPE) is a thermoplastic made from the monomer ethylene. It was the first grade of polyethylene, produced in 1933 by Dr John C. Swallow and M.W Perrin who were working for Imperial Chemical Industries (ICI) using a high pressure process via free radical polymerization. Its manufacture employs the same method today. The EPA estimates 5.7% of LDPE is recycled in the United States. Despite competition from more modern polymers, LDPE continues to be an important plastic grade. In 2013 the worldwide LDPE market reached a volume of about US$33 billion.

Intermediate bulk containers are industrial-grade containers engineered for the mass handling, transport, and storage of liquids, semi-solids, pastes, or solids. The two main categories of IBC tanks are flexible IBCs and rigid IBCs. Many IBCs are reused or repurposed.

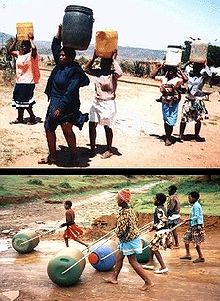

The Hippo water roller, or Hippo roller, is a device used to carry drinking water more easily and efficiently than traditional methods, particularly in the developing world and rural areas. It consists of a barrel-shaped container that holds the water and can roll along the ground, and a handle attached to the axis of the barrel. Currently deployed in rural Africa, its simple and purpose-built nature makes it an example of appropriate technology. The device cost around $125 each and they are mainly distributed by NGOs.

Plastic milk containers are plastic containers for storing, shipping and dispensing milk. Plastic bottles, sometimes called jugs, have largely replaced glass bottles for home consumption. Glass milk bottles have traditionally been reusable while light-weight plastic bottles are designed for single trips and plastic recycling.

Coated paper is paper that has been coated by a mixture of materials or a polymer to impart certain qualities to the paper, including weight, surface gloss, smoothness, or reduced ink absorbency. Various materials, including kaolinite, calcium carbonate, bentonite, and talc, can be used to coat paper for high-quality printing used in the packaging industry and in magazines.

The two-liter bottle is a common container for soft drinks, beer, and wine. These bottles are produced from polyethylene terephthalate, also known as PET plastic, or glass using the blow molding process. Bottle labels consist of a printed, tight-fitted plastic sleeve. A resealable screw-top allows the contents to be used at various times while retaining carbonation.

A plastic bottle is a bottle constructed from high-density or low density plastic. Plastic bottles are typically used to store liquids such as water, soft drinks, motor oil, cooking oil, medicine, shampoo, milk, ink, etc. They come in a range of sizes, from very small bottles to large carboys. Consumer blow molded containers often have integral handles or are shaped to facilitate grasping.

Caged IBC totes are one of, if not the most commonly used, of all current intermediate bulk container design types. Caged IBC totes are handling and shipping containers for the storing, transit, and operation integration of various commodities, with the most common being water. Caged IBCs are often utilized as one-use containers, especially when it comes to hazardous materials, but are also suitable for reuse under many conditions. This IBC type often features an interior liner, blow-mold manufactured from polyethylene, that is structurally supported by a protective cage frame, often of galvanized steel composition. Caged IBCs are engineered for the bulk handling of liquids, semi-solids, as well as solid materials. All materials can present certain safety and compatibility concerns, especially hazardous liquids, and proper guidance is always recommended whenever using caged IBC totes for harsh chemicals.

A fuel container is a container such as a steel can, bottle, drum, etc. for transporting, storing, and dispensing various fuels.