Related Research Articles

Spennymoor is a town and civil parish in County Durham, England. It stands above the Wear Valley approximately 7 mi (11 km) south of Durham. The town was founded over 160 years ago. The Town Council area, which includes the villages of Kirk Merrington, Middlestone Moor, Byers Green and Tudhoe, has a population of approximately 20,000.

Tudhoe is a village in County Durham, in England. It is situated approximately 8 km (5.0 mi) south of the city of Durham. It lies just outside Spennymoor, a short distance to the west of the Great North Road. The village is now a quiet backwater, its green a cul-de-sac that runs down from the main road towards the River Wear. In former times, however, Tudhoe lay at the centre of a network of roads: one ran to Durham by way of Sunderland Bridge and Croxdale, another to Kirk Merrington, a third to Bishop Auckland, a fourth to Whitworth and Byers Green, and a fifth across a ford to Brancepeth Castle and village on the far side of the river. All except the Brancepeth road are shown, somewhat schematically, on Thomas Jeffrey's map of County Durham of 1758.

Tow Law is a town and civil parish in County Durham, England. It is situated a few miles to the south of Consett.

Wolsingham is a small market town in Weardale, County Durham, England. It is situated by the River Wear, between Crook and Stanhope in North West Durham.

Weardale is a dale, or valley, of the east side of the Pennines in County Durham, England. Large parts of Weardale fall within the North Pennines Area of Outstanding Natural Beauty (AONB) – the second largest AONB in England and Wales. The upper valley is surrounded by high fells and heather grouse moors. The River Wear flows through Weardale before reaching Bishop Auckland and then Durham, meeting the sea at Sunderland.

The Dowlais Ironworks was a major ironworks and steelworks located at Dowlais near Merthyr Tydfil, in Wales. Founded in the 18th century, it operated until the end of the 20th, at one time in the 19th century being the largest steel producer in the UK. Dowlais Ironworks were the first business to license the Bessemer process, using it to produce steel in 1865. Dowlais Ironworks was one of the four principal ironworks in Merthyr. The other three were Cyfarthfa, Plymouth, and Penydarren Ironworks. In 1936 Dowlais played a part in the events leading to the abdication crisis of Edward VIII, when the King visited the steelworks and was reported as saying that "these works brought these men here. Something must be done to get them back to work", a statement which was seen as political interference. The steelworks finally closed in 1987.

Spennymoor United A.F.C. were an English association football club based in Spennymoor, County Durham.

The Lehigh Crane Iron Company was a major ironmaking firm in the Lehigh Valley from its founding in 1839 until its sale in 1899. It was founded under the patronage of Josiah White and Erskine Hazard, and financed by their Lehigh Coal & Navigation Company, which hoped to promote the then-novel technique of smelting iron ore with anthracite coal. This was an important cost and energy savings technique, since either an expensive charcoaling nor coke producing process and transport costs was totally eliminated so produced a great acceleration in the underpinnings of the American industrial revolution.

John Vaughan, known as Jacky, was born in Worcester on "St Thomas' Day" in 1799, the son of Welsh parents. He worked his way up the iron industry, becoming an ironmaster and co-founder of the largest of all the Victorian iron and steel companies, Bolckow Vaughan. Where Henry Bolckow provided the investment and business expertise, Vaughan contributed technical knowledge, in a long-lasting and successful partnership that transformed Middlesbrough from a small town to the centre of ironmaking in Britain.

The Consett Iron Company Ltd was an industrial business based in the Consett area of County Durham in the United Kingdom. The company owned coal mines and limestone quarries, and manufactured iron and steel. It was registered on 4 April 1864 as successor to the Derwent & Consett Iron Company Ltd. This in turn was the successor to the Derwent Iron Company, founded in 1840.

The British Iron Company was formed in 1824 to smelt and manufacture iron and to mine ironstone, coal, etc. It was re-formed as the New British Iron Company in 1843 and liquidated itself in 1892.

The Grubb Family Iron Dynasty was a succession of iron manufacturing enterprises owned and operated by Grubb family members for more than 165 years. Collectively, they were Pennsylvania's leading iron manufacturer between 1840 and 1870.

Ebbw Vale Steelworks was an integrated steel mill located in Ebbw Vale, South Wales. Developed from 1790, by the late 1930s it had become the largest steel mill in Europe. Nationalized after World War II, as the steel industry changed to bulk handling, iron and steel making was ceased in the 1970s, as the site was redeveloped as a specialised tinplate works. Closed by Corus in 2002, the site is being redeveloped in a joint-partnership between Blaenau Gwent Council and the Welsh Government.

Tredegar Iron and Coal Company was an important 19th century ironworks in Tredegar, Wales, which due to its need for coke became a major developer of coal mines and particularly the Sirhowy Valley of South Wales. It is most closely associated with the Industrial Revolution and coal mining in the South Wales Valleys.

Losh, Wilson and Bell, later Bells, Goodman, then Bells, Lightfoot and finally Bell Brothers, was a leading Northeast England manufacturing company, founded in 1809 by the partners William Losh, Thomas Wilson, and Thomas Bell.

Bolckow, Vaughan & Co., Ltd was an English ironmaking and mining company founded in 1864, based on the partnership since 1840 of its two founders, Henry Bolckow and John Vaughan. The firm drove the dramatic growth of Middlesbrough and the production of coal and iron in the north-east of England in the 19th century. The two founding partners had an exceptionally close working relationship which lasted until Vaughan's death.

Witton Park Colliery was a coal mine in Witton Park, Witton-le-Wear near Bishop Auckland, County Durham, Northern England.

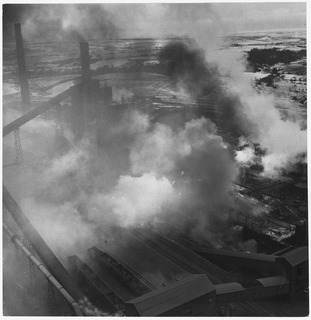

The Low Moor Ironworks was a wrought iron foundry established in 1791 in the village of Low Moor about 3 miles (4.8 km) south of Bradford in Yorkshire, England. The works were built to exploit the high-quality iron ore and low-sulphur coal found in the area. Low Moor made wrought iron products from 1801 until 1957 for export around the world. At one time it was the largest ironworks in Yorkshire, a major complex of mines, piles of coal and ore, kilns, blast furnaces, forges and slag heaps connected by railway lines. The surrounding countryside was littered with waste, and smoke from the furnaces and machinery blackened the sky. Today Low Moor is still industrial, but the pollution has been mostly eliminated.

The Lithgow Blast Furnace is a heritage-listed former blast furnace and now park and visitor attraction at Inch Street, Lithgow, City of Lithgow, New South Wales, Australia. It was built from 1906 to 1907 by William Sandford Limited. It is also known as Eskbank Ironworks Blast Furnace site; Industrial Archaeological Site. The property is owned by Lithgow City Council. It was added to the New South Wales State Heritage Register on 2 April 1999.

References

- 1 2 3 4 5 "Attwood, Charles". Oxford Dictionary of National Biography (online ed.). Oxford University Press. doi:10.1093/ref:odnb/52577.(Subscription or UK public library membership required.)

- 1 2 "Tow Law" Tow Law Community Association. Retrieved 25 February 2020.

- 1 2 3 "History of Spennymoor" Tudhoe and Spennymoor Local History Society. Retrieved 25 February 2020.