The X-engine is a type of pistonless rotary engine manufactured by LiquidPiston of Bloomfield, Connecticut.

Contents

The X engine is a hybrid cycle rotary engine.

The X-engine is a type of pistonless rotary engine manufactured by LiquidPiston of Bloomfield, Connecticut.

The X engine is a hybrid cycle rotary engine.

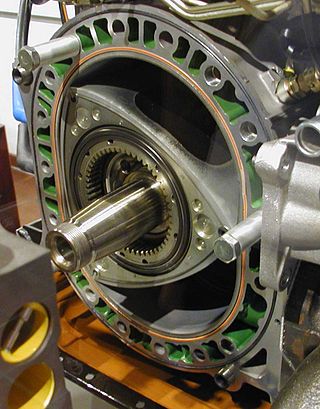

This is geometrically an inverted Wankel engine that operates on the high-efficiency hybrid cycle. [1] [2] In the Wankel, the only successful pistonless rotary engine to date, a figure-eight-like epitrochoid housing surrounds a curved sided triangular rotor. The rotor revolves around a fixed gear in a hula-hoop motion. The output shaft revolves at three times the speed of the rotor. One power pulse is delivered in one revolution of the output shaft. For comparison a single cylinder four-stroke piston engine delivers one power pulse for two rotations of the output shaft. The three operating chambers of the Wankel formed by the triangular rotor are separated by seals installed on the three apexes of the rotor. They require elaborate lubrication, and in older designs have been a weak point for the engine's durability. The LiquidPiston design reverses the shapes: a figure-eight-shaped rotor moves within a triangular housing. The required seals (both face and apex) are mounted on the stationary housing, which makes lubrication much easier. Common to both concepts is the use of ports to supply air and remove exhaust gas, thereby eliminating the need for valves.

This cycle consists of compressing air (with no fuel) to a very high ratio, as is typical in the Diesel cycle. The air is then isolated in a constant volume chamber. Fuel is directly injected being allowed to combust fully under constant volume conditions, which is how Otto cycle combustion is modelled. Finally, the combustion products are expanded to atmospheric pressure, utilizing the Atkinson cycle.

In order to use the Diesel cycle efficiently, high compression ratios are required: Typical engines use between 15:1 and 24:1. The LiquidPiston engine was demonstrated on the Diesel cycle with a compression ratio as high as 26:1. [3] This would generally rule out the use of low-octane fuels like gasoline. Therefore a spark-ignited variant with lower compression was developed. This so-called "X-Mini" is a 70 cc air-cooled naturally aspirated four-stroke X-Engine, and has been demonstrated on gasoline, kerosene, Jet A fuel, propane and hydrogen. [4]

A reciprocating engine, also often known as a piston engine, is typically a heat engine that uses one or more reciprocating pistons to convert high temperature and high pressure into a rotating motion. This article describes the common features of all types. The main types are: the internal combustion engine, used extensively in motor vehicles; the steam engine, the mainstay of the Industrial Revolution; and the Stirling engine for niche applications. Internal combustion engines are further classified in two ways: either a spark-ignition (SI) engine, where the spark plug initiates the combustion; or a compression-ignition (CI) engine, where the air within the cylinder is compressed, thus heating it, so that the heated air ignites fuel that is injected then or earlier.

The Wankel engine is a type of internal combustion engine using an eccentric rotary design to convert pressure into rotating motion. The concept was proven by German engineer Felix Wankel, followed by a commercially feasible engine designed by German engineer Hanns-Dieter Paschke. The Wankel engine's rotor, which creates the turning motion, is similar in shape to a Reuleaux triangle, with the sides having less curvature. The rotor spins inside a figure-eight-like epitrochoidal housing around a fixed-toothed gearing. The midpoint of the rotor moves in a circle around the output shaft, rotating the shaft via a cam.

A two-strokeengine is a type of internal combustion engine that completes a power cycle with two strokes of the piston in one revolution of the crankshaft. A four-stroke engine requires four strokes of the piston to complete a power cycle in two crankshaft revolutions. In a two-stroke engine, the end of the combustion stroke and the beginning of the compression stroke happen simultaneously, with the intake and exhaust functions occurring at the same time.

An aircraft engine, often referred to as an aero engine, is the power component of an aircraft propulsion system. Aircraft using power components are referred to as powered flight. Most aircraft engines are either piston engines or gas turbines, although a few have been rocket powered and in recent years many small UAVs have used electric motors.

A petrol engine is an internal combustion engine designed to run on petrol (gasoline). Petrol engines can often be adapted to also run on fuels such as liquefied petroleum gas and ethanol blends.

A four-strokeengine is an internal combustion (IC) engine in which the piston completes four separate strokes while turning the crankshaft. A stroke refers to the full travel of the piston along the cylinder, in either direction. The four separate strokes are termed:

The Brayton cycle, also known as the Joule cycle, is a thermodynamic cycle that describes the operation of certain heat engines that have air or some other gas as their working fluid. It is characterized by isentropic compression and expansion, and isobaric heat addition and rejection, though practical engines have adiabatic rather than isentropic steps.

A compressor is a mechanical device that increases the pressure of a gas by reducing its volume. An air compressor is a specific type of gas compressor.

The Atkinson-cycle engine is a type of internal combustion engine invented by James Atkinson in 1882. The Atkinson cycle is designed to provide efficiency at the expense of power density.

The Mazda Wankel engines are a family of Wankel rotary combustion car engines produced by Mazda.

A pistonless rotary engine is an internal combustion engine that does not use pistons in the way a reciprocating engine does. Designs vary widely but typically involve one or more rotors, sometimes called rotary pistons. Although many different designs have been constructed, only the Wankel engine has achieved widespread adoption.

Homogeneous Charge Compression Ignition (HCCI) is a form of internal combustion in which well-mixed fuel and oxidizer are compressed to the point of auto-ignition. As in other forms of combustion, this exothermic reaction produces heat that can be transformed into work in a heat engine.

A swing-piston engine is a type of internal combustion engine in which the pistons move in a circular motion inside a ring-shaped "cylinder", moving closer and further from each other to provide compression and expansion. Generally two sets of pistons are used, geared to move in a fixed relationship as they rotate around the cylinder. In some versions the pistons oscillate around a fixed center, as opposed to rotating around the entire engine. The design has also been referred to as a oscillating piston engine, vibratory engine when the pistons oscillate instead of rotate, or toroidal engine based on the shape of the "cylinder".

Engine efficiency of thermal engines is the relationship between the total energy contained in the fuel, and the amount of energy used to perform useful work. There are two classifications of thermal engines-

The Norton Classic is a rotary-engined motorcycle built in 1987 by Norton as a special edition of just 100 machines.

The high-efficiency hybrid cycle (HEHC) is a new 4-stroke thermodynamic cycle combining elements of the Otto cycle, Diesel cycle, Atkinson cycle and Rankine cycle.

Internal combustion engines come in a wide variety of types, but have certain family resemblances, and thus share many common types of components.

The MidWest AE series are lightweight, liquid-cooled, single- and twin-rotor Wankel engines, with dual ignition, designed for light aircraft. They were produced by Mid-West Engines Ltd. at Staverton Airport, Gloucestershire, UK.

An internal combustion engine is a heat engine in which the combustion of a fuel occurs with an oxidizer in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal combustion engine, the expansion of the high-temperature and high-pressure gases produced by combustion applies direct force to some component of the engine. The force is typically applied to pistons, turbine blades, a rotor, or a nozzle. This force moves the component over a distance, transforming chemical energy into kinetic energy which is used to propel, move or power whatever the engine is attached to.

Wankel Diesel engine describes the idea of using the Diesel principle in a Wankel rotary engine. Several attempts to build such an engine have been made by different engineers and manufacturers in the 1960s and 1970s. Due to technical problems and the general disadvantages of the Wankel design, the Wankel Diesel engine never left the prototype stage, and designing a Wankel Diesel engine capable of running under its own power is thus considered unfeasible.