A hybrid-propellant rocket is a rocket with a rocket motor that uses rocket propellants in two different phases: one solid and the other either gas or liquid. The hybrid rocket concept can be traced back to the early 1930s.

A hypergolic propellant is a rocket propellant combination used in a rocket engine, whose components spontaneously ignite when they come into contact with each other.

A rocket engine uses stored rocket propellants as the reaction mass for forming a high-speed propulsive jet of fluid, usually high-temperature gas. Rocket engines are reaction engines, producing thrust by ejecting mass rearward, in accordance with Newton's third law. Most rocket engines use the combustion of reactive chemicals to supply the necessary energy, but non-combusting forms such as cold gas thrusters and nuclear thermal rockets also exist. Vehicles propelled by rocket engines are commonly called rockets. Rocket vehicles carry their own oxidiser, unlike most combustion engines, so rocket engines can be used in a vacuum to propel spacecraft and ballistic missiles.

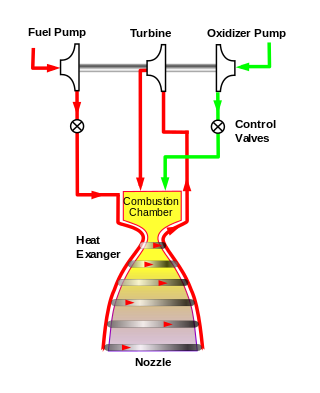

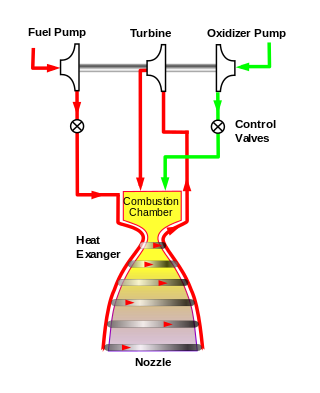

The expander cycle is a power cycle of a bipropellant rocket engine. In this cycle, the fuel is used to cool the engine's combustion chamber, picking up heat and changing phase. The now heated and gaseous fuel then powers the turbine that drives the engine's fuel and oxidizer pumps before being injected into the combustion chamber and burned.

A liquid-propellant rocket or liquid rocket utilizes a rocket engine that uses liquid propellants. Gaseous propellants may also be used but are not common because of their low density and difficulty with common pumping methods. Liquids are desirable because they have a reasonably high density and high specific impulse (Isp). This allows the volume of the propellant tanks to be relatively low. The rocket propellants are usually pumped into the combustion chamber with a lightweight centrifugal turbopump, although some aerospace companies have found ways to use electric pumps with batteries, allowing the propellants to be kept under low pressure. This permits the use of low-mass propellant tanks that do not need to resist the high pressures needed to store significant amounts of gasses, resulting in a low mass ratio for the rocket.

The Aerojet Rocketdyne RS-25, also known as the Space Shuttle Main Engine (SSME), is a liquid-fuel cryogenic rocket engine that was used on NASA's Space Shuttle and is currently used on the Space Launch System (SLS).

The J-2 is a liquid-fuel cryogenic rocket engine used on NASA's Saturn IB and Saturn V launch vehicles. Built in the U.S. by Rocketdyne, the J-2 burned cryogenic liquid hydrogen (LH2) and liquid oxygen (LOX) propellants, with each engine producing 1,033.1 kN (232,250 lbf) of thrust in vacuum. The engine's preliminary design dates back to recommendations of the 1959 Silverstein Committee. Rocketdyne won approval to develop the J-2 in June 1960 and the first flight, AS-201, occurred on 26 February 1966. The J-2 underwent several minor upgrades over its operational history to improve the engine's performance, with two major upgrade programs, the de Laval nozzle-type J-2S and aerospike-type J-2T, which were cancelled after the conclusion of the Apollo program.

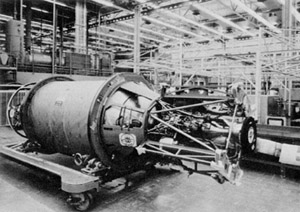

The Rocketdyne H-1 was a 205,000 lbf (910 kN) thrust liquid-propellant rocket engine burning LOX and RP-1. The H-1 was developed for use in the S-I and S-IB first stages of the Saturn I and Saturn IB rockets, respectively, where it was used in clusters of eight engines. After the Apollo program, surplus H-1 engines were rebranded and reworked as the Rocketdyne RS-27 engine with first usage on the Delta 2000 series in 1974. The RS-27 variant is also used on the Delta II and Delta III.

The highest specific impulse chemical rockets use liquid propellants. They can consist of a single chemical or a mix of two chemicals, called bipropellants. Bipropellants can further be divided into two categories; hypergolic propellants, which ignite when the fuel and oxidizer make contact, and non-hypergolic propellants which require an ignition source.

The staged combustion cycle is a power cycle of a bipropellant rocket engine. In the staged combustion cycle, propellant flows through multiple combustion chambers, and is thus combusted in stages. The main advantage relative to other rocket engine power cycles is high fuel efficiency, measured through specific impulse, while its main disadvantage is engineering complexity.

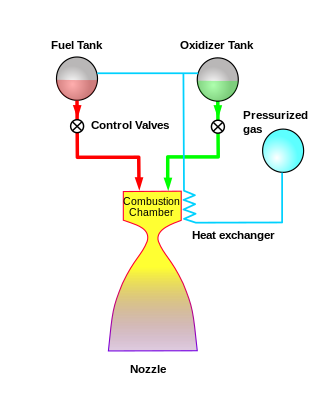

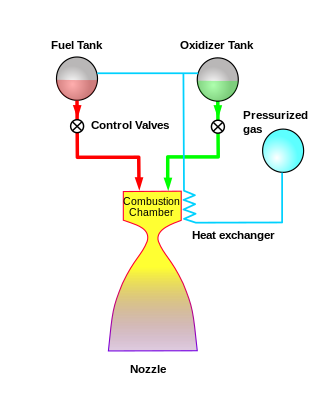

The pressure-fed engine is a class of rocket engine designs. A separate gas supply, usually helium, pressurizes the propellant tanks to force fuel and oxidizer to the combustion chamber. To maintain adequate flow, the tank pressures must exceed the combustion chamber pressure.

Vulcain is a family of European first stage rocket engines for Ariane 5 and the future Ariane 6. Its development began in 1988 and the first flight was completed in 1996. The updated version of the engine, Vulcain 2, was first successfully flown in 2005. Both members of the family use liquid oxygen/liquid hydrogen cryogenic fuel. The new version under development for Ariane 6 will be called Vulcain 2.1.

The Viking rocket engines were members of a series of bipropellant engines for the first and second stages of the Ariane 1 through Ariane 4 commercial launch vehicles, using storable, hypergolic propellants: dinitrogen tetroxide and UH 25, a mixture of 75% UDMH and 25% hydrazine.

A cryogenic rocket engine is a rocket engine that uses a cryogenic fuel and oxidizer; that is, both its fuel and oxidizer are gases which have been liquefied and are stored at very low temperatures. These highly efficient engines were first flown on the US Atlas-Centaur and were one of the main factors of NASA's success in reaching the Moon by the Saturn V rocket.

The LR87 was an American liquid-propellant rocket engine used on the first stages of Titan intercontinental ballistic missiles and launch vehicles. Composed of twin motors with separate combustion chambers and turbopump machinery, it is considered a single unit and was never flown as a single combustion chamber engine or designed for this. The LR87 first flew in 1959.

Rocket propellant is the reaction mass of a rocket. This reaction mass is ejected at the highest achievable velocity from a rocket engine to produce thrust. The energy required can either come from the propellants themselves, as with a chemical rocket, or from an external source, as with ion engines.

This page is an incomplete list of orbital rocket engine data and specifications.

The descent propulsion system or lunar module descent engine (LMDE), internal designation VTR-10, is a variable-throttle hypergolic rocket engine invented by Gerard W. Elverum Jr. and developed by Space Technology Laboratories (TRW) for use in the Apollo Lunar Module descent stage. It used Aerozine 50 fuel and dinitrogen tetroxide oxidizer. This engine used a pintle injector, which paved the way for other engines to use similar designs.

A liquid apogee engine (LAE), or apogee engine, refers to a type of chemical rocket engine typically used as the main engine in a spacecraft.

The Bell Aerosystems Company XLR81 was an American liquid-propellant rocket engine, which was used on the Agena upper stage. It burned UDMH and RFNA fed by a turbopump in a fuel rich gas generator cycle. The turbopump had a single turbine with a gearbox to transmit power to the oxidizer and fuel pumps. The thrust chamber was all-aluminum, and regeneratively cooled by oxidizer flowing through gun-drilled passages in the combustion chamber and throat walls. The nozzle was a titanium radiatively cooled extension. The engine was mounted on a hydraulic actuated gimbal which enabled thrust vectoring to control pitch and yaw. Engine thrust and mixture ratio were controlled by cavitating flow venturis on the gas generator flow circuit. Engine start was achieved by solid propellant start cartridge.