A monopropellant rocket is a rocket that uses a single chemical as its propellant. Monopropellant rockets are commonly used as small attitude and trajectory control rockets in satellites, rocket upper stages, crewed spacecraft, and spaceplanes.

A hypergolic propellant is a rocket propellant combination used in a rocket engine, whose components spontaneously ignite when they come into contact with each other.

A rocket engine is a reaction engine, producing thrust in accordance with Newton's third law by ejecting reaction mass rearward, usually a high-speed jet of high-temperature gas produced by the combustion of rocket propellants stored inside the rocket. However, non-combusting forms such as cold gas thrusters and nuclear thermal rockets also exist. Rocket vehicles carry their own oxidiser, unlike most combustion engines, so rocket engines can be used in a vacuum, and they can achieve great speed, beyond escape velocity. Vehicles commonly propelled by rocket engines include missiles, artillery shells, ballistic missiles and rockets of any size, from tiny fireworks to man-sized weapons to huge spaceships.

AS-201, flown February 26, 1966, was the first uncrewed test flight of an entire production Block I Apollo command and service module and the Saturn IB launch vehicle. The spacecraft consisted of the second Block I command module and the first Block I service module. The suborbital flight was a partially successful demonstration of the service propulsion system and the reaction control systems of both modules, and successfully demonstrated the capability of the command module's heat shield to survive re-entry from low Earth orbit.

A liquid-propellant rocket or liquid rocket uses a rocket engine burning liquid propellants. (Alternate approaches use gaseous or solid propellants.) Liquids are desirable propellants because they have reasonably high density and their combustion products have high specific impulse (Isp). This allows the volume of the propellant tanks to be relatively low.

The J-2, commonly known as Rocketdyne J-2, was a liquid-fuel cryogenic rocket engine used on NASA's Saturn IB and Saturn V launch vehicles. Built in the United States by Rocketdyne, the J-2 burned cryogenic liquid hydrogen (LH2) and liquid oxygen (LOX) propellants, with each engine producing 1,033.1 kN (232,250 lbf) of thrust in vacuum. The engine's preliminary design dates back to recommendations of the 1959 Silverstein Committee. Rocketdyne won approval to develop the J-2 in June 1960 and the first flight, AS-201, occurred on 26 February 1966. The J-2 underwent several minor upgrades over its operational history to improve the engine's performance, with two major upgrade programs, the de Laval nozzle-type J-2S and aerospike-type J-2T, which were cancelled after the conclusion of the Apollo program.

The Apollo command and service module (CSM) was one of two principal components of the United States Apollo spacecraft, used for the Apollo program, which landed astronauts on the Moon between 1969 and 1972. The CSM functioned as a mother ship, which carried a crew of three astronauts and the second Apollo spacecraft, the Apollo Lunar Module, to lunar orbit, and brought the astronauts back to Earth. It consisted of two parts: the conical command module, a cabin that housed the crew and carried equipment needed for atmospheric reentry and splashdown; and the cylindrical service module which provided propulsion, electrical power and storage for various consumables required during a mission. An umbilical connection transferred power and consumables between the two modules. Just before reentry of the command module on the return home, the umbilical connection was severed and the service module was cast off and allowed to burn up in the atmosphere.

The highest specific impulse chemical rockets use liquid propellants. They can consist of a single chemical or a mix of two chemicals, called bipropellants. Bipropellants can further be divided into two categories; hypergolic propellants, which ignite when the fuel and oxidizer make contact, and non-hypergolic propellants which require an ignition source.

The Altair spacecraft, previously known as the Lunar Surface Access Module or LSAM, was the planned lander spacecraft component of NASA's cancelled Constellation program. Astronauts would have used the spacecraft for landings on the Moon, which was intended to begin around 2019. The Altair spacecraft was planned to be used both for lunar sortie and lunar outpost missions.

A pistonless pump is a type of pump designed to move fluids without any moving parts other than three chamber valves.

A cryogenic rocket engine is a rocket engine that uses a cryogenic fuel and oxidizer; that is, both its fuel and oxidizer are gases which have been liquefied and are stored at very low temperatures. These highly efficient engines were first flown on the US Atlas-Centaur and were one of the main factors of NASA's success in reaching the Moon by the Saturn V rocket.

The descent propulsion system or lunar module descent engine (LMDE), internal designation VTR-10, is a variable-throttle hypergolic rocket engine invented by Gerard W. Elverum Jr. and developed by Space Technology Laboratories (TRW) for use in the Apollo Lunar Module descent stage. It used Aerozine 50 fuel and dinitrogen tetroxide oxidizer. This engine used a pintle injector, which paved the way for other engines to use similar designs.

The TR-201 or TR201 is a hypergolic pressure-fed rocket engine used to propel the upper stage of the Delta rocket, referred to as Delta-P, from 1972 to 1988. The rocket engine uses Aerozine 50 as fuel, and N

2O

4 as oxidizer. It was developed in the early 1970s by TRW as a derivative of the lunar module descent engine (LMDE). This engine used a pintle injector first invented by Gerard W. Elverum Jr. and developed by TRW in the late 1950s and received US Patent in 1972. This injector technology and design is also used on SpaceX Merlin engines.

The ascent propulsion system (APS) or lunar module ascent engine (LMAE) is a fixed-thrust hypergolic rocket engine developed by Bell Aerosystems for use in the Apollo Lunar Module ascent stage. It used Aerozine 50 fuel, and N

2O

4 oxidizer. Rocketdyne provided the injector system, at the request of NASA, when Bell could not solve combustion instability problems.

Since the founding of SpaceX in 2002, the company has developed four families of rocket engines — Merlin, Kestrel, Draco and SuperDraco — and since 2016 developed the Raptor methane rocket engine and after 2020, a line of methalox thrusters.

Aestus is a hypergolic liquid rocket engine used on an upper stage of Ariane 5 family rockets for the orbital insertion. It features unique design of 132 coaxial injection elements causing swirl mixing of the MMH propellants with nitrogen tetroxide oxidizer. The pressure-fed engine allows for multiple re-ignitions.

The KTDU-80 (Russian: Корректирующе-Тормозная Двигательная Установка, КТДУ) is the latest of a family of integrated propulsion system that KB KhIMMASH has implemented for the Soyuz since the Soyuz-T. It integrates main propulsion, RCS and attitude control in a single system pressure fed from a common dual string redundant pressurized propellant system. The common propellant is UDMH and N2O4 and the main propulsion unit is the S5.80 main engine. It generates 2.95 kN (660 lbf) of thrust with a chamber pressure of 880 kPa (128 psi) and a nozzle expansion of 153.8 that enables it to achieve a specific impulse of 302 s (2.96 km/s). It is rated for 30 starts with a total firing time of 890 seconds. The integrated system without the pressurization or tanks weighs 310 kg (680 lb); it is 1.2 m (47 in) long with a diameter of 2.1 m (83 in).

The A.M. Isayev Chemical Engineering Design Bureau, also known as KB KhimMash or just KBKhM, is a Russian rocket engine design and manufacturing company. It is located in the city of Korolyov. It started as the OKB-2 division of the NII-88 research institute, where A.Isaev directed the development of liquid rocket engines for ballistic missile submarines.

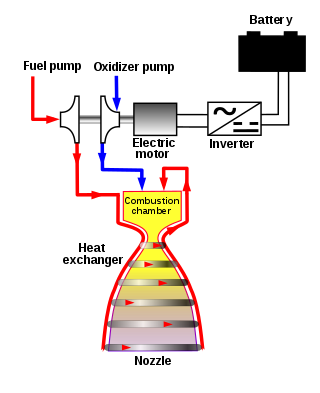

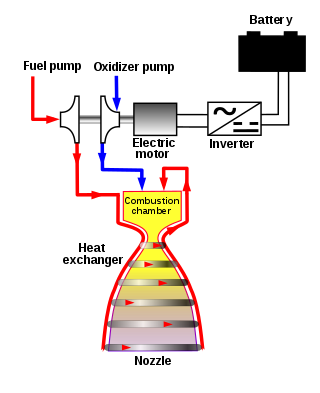

The electric-pump-fed engine is a bipropellant rocket engine in which the fuel pumps are electrically powered, and so all of the input propellant is directly burned in the main combustion chamber, and none is diverted to drive the pumps. This differs from traditional rocket engine designs, in which the pumps are driven by a portion of the input propellants.

Autogenous pressurization is the use of self-generated gaseous propellant to pressurize liquid propellant in rockets. Traditional liquid-propellant rockets have been most often pressurized with other gases, such as helium, which necessitates carrying the pressurant tanks along with the plumbing and control system to use it. Autogenous pressurization has been operationally used on the Titan 34D, Space Shuttle, Space Launch System, and Starship. Autogenous pressurization is planned to be used on the New Glenn, Terran 1 and Rocket Lab's Neutron rocket.