A carton is a box or container usually made of liquid packaging board, paperboard and sometimes of corrugated fiberboard. Many types of cartons are used in packaging. Sometimes a carton is also called a box.

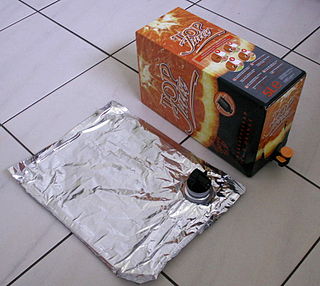

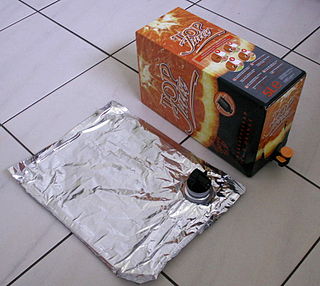

A bag-in-box or BiB is a container for the storage and transportation of liquids. It consists of a strong bladder, usually made of several layers of metallised film or other plastics, seated inside a corrugated fiberboard box.

Modified atmosphere packaging (MAP) is the practice of modifying the composition of the internal atmosphere of a package in order to improve the shelf life. The need for this technology for food arises from the short shelf life of food products such as meat, fish, poultry, and dairy in the presence of oxygen. In food, oxygen is readily available for lipid oxidation reactions. Oxygen also helps maintain high respiration rates of fresh produce, which contribute to shortened shelf life. From a microbiological aspect, oxygen encourages the growth of aerobic spoilage microorganisms. Therefore, the reduction of oxygen and its replacement with other gases can reduce or delay oxidation reactions and microbiological spoilage. Oxygen scavengers may also be used to reduce browning due to lipid oxidation by halting the auto-oxidative chemical process. Besides, MAP changes the gaseous atmosphere by incorporating different compositions of gases.

Blow molding is a manufacturing process for forming hollow plastic parts. It is also used for forming glass bottles or other hollow shapes.

An ampoule is a small sealed vial which is used to contain and preserve a sample, usually a solid or liquid. Ampoules are usually made of glass.

A glass bottle is a bottle made from glass. Glass bottles can vary in size considerably, but are most commonly found in sizes ranging between about 200 millilitres and 1.5 litres. Common uses for glass bottles include food condiments, soda, liquor, cosmetics, pickling and preservatives; they are occasionally also notably used for the informal distribution of notes. These types of bottles are utilitarian and serve a purpose in commercial industries.

Rotary wheel blow molding systems are used for the high-output production of a wide variety of plastic extrusion blow molded articles. Containers may be produced from small, single serve bottles to large containers up to 20-30 liters in volume - but wheel machines are often sized for the volume and dimensional demands of a specific container, and are typically dedicated to a narrow range of bottle sizes once built. Multiple parison machines, with high numbers of molds are capable of producing over one million bottles per day in some configurations.

A blister pack is any of several types of pre-formed plastic packaging used for small consumer goods, foods, and for pharmaceuticals.

Plastic milk containers are plastic containers for storing, shipping and dispensing milk. Plastic bottles, sometimes called jugs, have largely replaced glass bottles for home consumption. Glass milk bottles have traditionally been reusable while light-weight plastic bottles are designed for single trips and plastic recycling.

In-mould labelling is the use of paper or plastic labels during the manufacturing of containers by blow molding, injection molding, or thermoforming processes. The label serves as the integral part of the final product, which is then delivered as pre-decorated item. Combining the decoration process with the moulding process cuts the total cost, but can increase the manufacturing time. The technology was first developed by Owens-Illinois in cooperation with Procter & Gamble to supply pre-labelled bottles that could be filled on the product filling line. This was first applied to Head & Shoulders shampoo bottles.

Tetra Pak is a multinational food packaging and processing company headquartered in Switzerland. The company offers packaging, filling machines and processing for dairy, beverages, cheese, ice cream and prepared food, including distribution tools like accumulators, cap applicators, conveyors, crate packers, film wrappers, line controllers and straw applicators.

A plastic bottle is a bottle constructed from high-density or low density plastic. Plastic bottles are typically used to store liquids such as water, soft drinks, motor oil, cooking oil, medicine, shampoo, milk, and ink. The size ranges from very small bottles to large carboys. Consumer blow molded containers often have integral handles or are shaped to facilitate grasping.

A juice box, also called a carton (BrE) or popper (AuE), is a small container used to conveniently carry and consume drinks. They are frequently made of paperboard with an aluminum foil lining, but variations exist. Juice boxes are most popular with children, although other uses include emergency drinking water, milk, and wine.

Aseptic processing is a processing technique wherein commercially thermally sterilized liquid products are packaged into previously sterilized containers under sterile conditions to produce shelf-stable products that do not need refrigeration. Aseptic processing has almost completely replaced in-container sterilization of liquid foods, including milk, fruit juices and concentrates, cream, yogurt, salad dressing, liquid egg, and ice cream mix. There has been an increasing popularity for foods that contain small discrete particles, such as cottage cheese, baby foods, tomato products, fruit and vegetables, soups, and rice desserts.

Glass production involves two main methods – the float glass process that produces sheet glass, and glassblowing that produces bottles and other containers. It has been done in a variety of ways during the history of glass.

A stand-up pouch or doypack is a type of flexible packaging that is able to stand erect on its bottom for display, storage, and convenience. It has characteristics of plastic bags, water bottles, and retort pouches. The bottom part of a stand-up pouch is gusseted to provide support for display or use.

Krones AG is a German packaging and bottling machine manufacturer. It produces lines for filling beverages in plastic and glass bottles or beverage cans. The company manufactures stretch blow-moulding machines for producing polyethylene terephthalate (PET) bottles, plus fillers, labellers, bottle washers, pasteurisers, inspectors, packers and palletisers. This product portfolio is complemented by material flow systems and process technology for producing beverages for breweries, dairies and soft-drink companies.

Sidel is a manufacturing company providing equipment and services for packaging liquids such as water; carbonated and non-carbonated soft drinks; sensitive beverages such as milk, liquid dairy products, juices, tea, coffee, isotonics and beer; food and home and personal care.

Solopharm – Russian pharmaceutical company, which produces liquid sterile dosage forms according to GMP standards. Product line consists of infusion and injection solutions, ophthalmic, otolaryngological, gastroenterological, rheumatological and cosmetological products.

ApiJect Systems Corporation is an American company founded in 2018 by Marc Koska and based in Stamford, Connecticut that produces pre-filled single use plastic injectors. ApiJect works with pharmaceutical and biotech companies to fill their injectable drug products into single-dose prefilled injectors. The company claimed to have the capacity to manufacture pre-filled COVID-19 vaccine syringes by the end of 2020.