Glass is a non-crystalline solid that is often transparent, brittle and chemically inert. It has widespread practical, technological, and decorative use in, for example, window panes, tableware, and optics.

Lapidary is the practice of shaping stone, minerals, or gemstones into decorative items such as cabochons, engraved gems, and faceted designs. A person who practices lapidary is known as a lapidarist. A lapidarist uses the lapidary techniques of cutting, grinding, and polishing. Hardstone carving requires specialized carving techniques.

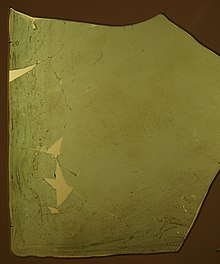

Float glass is a sheet of glass made by floating molten glass on a bed of molten metal of a low melting point, typically tin, although lead was used for the process in the past. This method gives the sheet uniform thickness and a very flat surface.

An abrasive is a material, often a mineral, that is used to shape or finish a workpiece through rubbing which leads to part of the workpiece being worn away by friction. While finishing a material often means polishing it to gain a smooth, reflective surface, the process can also involve roughening as in satin, matte or beaded finishes. In short, the ceramics which are used to cut, grind and polish other softer materials are known as abrasives.

Beveled glass is usually made by taking thick glass and creating an angled surface cut (bevel) around the entire periphery. Bevels act as prisms in sunlight creating an interesting color refraction which both highlights the glass work and provides a spectrum of colors which would ordinarily be absent in clear float glass.

A brayer is a hand-tool used historically in printing and printmaking to break up and "rub out" (spread) ink, before it was "beaten" using inking balls or composition rollers. A brayer consists of a short wooden cylinder with a handle fitted to one end; the other, flat end is used to rub the ink.

Glass tubes are mainly cylindrical hollow-wares. Their special shape combined with the huge variety of glass types, allows the use of glass tubing in many applications. For example, laboratory glassware, lighting applications, solar thermal systems and pharmaceutical packaging to name the largest.

Lapping is a machining process in which two surfaces are rubbed together with an abrasive between them, by hand movement or using a machine.

Blown plate is a hand-blown glass. There is a record of blown plate being produced in London in 1620.

Broad sheet is a type of hand-blown glass. It was first made in Sussex in 1226.

Polished plate is a type of hand-made glass. It is produced by casting glass onto a table and then subsequently grinding and polishing the glass. This was originally done by hand, and then later by machine. It was an expensive process requiring a large capital investment.

Cylinder blown sheet is a type of hand-blown window glass. It is created with a similar process to broad sheet, but with the use of larger cylinders. In this manufacturing process glass is blown into a cylindrical iron mold. The ends are cut off and a cut is made down the side of the cylinder. The cut cylinder is then placed in an oven where the cylinder unrolls into a flat glass sheet. William J. Blenko used this method in the early 1900s to make stained glass. The result is much larger panes and improved surface quality over broad sheet, although still containing some imperfections. These imperfect panes have led to the misconception that glass is actually a high-viscosity fluid at room temperature, which is not the case.

Machine drawn cylinder sheet was the first mechanical method for "drawing" window glass. Cylinders of glass 40 feet (12 m) high are drawn vertically from a circular tank. The glass is then annealed and cut into 7 to 10 foot cylinders. These are cut lengthways, reheated, and flattened.

Crown glass was an early type of window glass. In this process, glass was blown into a "crown" or hollow globe. This was then transferred from the blowpipe to a punty and then flattened by reheating and spinning out the bowl-shaped piece of glass (bullion) into a flat disk by centrifugal force, up to 5 or 6 feet in diameter. The glass was then cut to the size required.

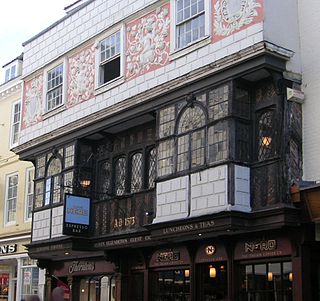

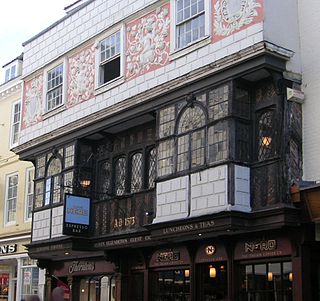

Architectural glass is glass that is used as a building material. It is most typically used as transparent glazing material in the building envelope, including windows in the external walls. Glass is also used for internal partitions and as an architectural feature. When used in buildings, glass is often of a safety type, which include reinforced, toughened and laminated glasses.

Coffee preparation is the process of turning coffee beans into liquid coffee. While the particular steps vary with the type of coffee and with the raw materials, the process includes four basic steps: raw coffee beans must be roasted, the roasted coffee beans must then be ground, and the ground coffee must then be mixed with hot or cold water for a specific time (brewed), the liquid coffee extraction must be separated from the used grounds, and finally, if desired, the extracted coffee is combined with other elements of the desired beverage, such as sweeteners, dairy products, dairy alternatives, or toppings.

Soda–lime glass, also called soda–lime–silica glass, is the most prevalent type of glass, used for windowpanes and glass containers for beverages, food, and some commodity items. Some glass bakeware is made of soda-lime glass, as opposed to the more common borosilicate glass. Soda–lime glass accounts for about 90% of manufactured glass.

Glass production involves two main methods – the float glass process that produces sheet glass, and glassblowing that produces bottles and other containers. It has been done in a variety of ways during the history of glass.

The history of glass-making dates back to at least 3,600 years ago in Mesopotamia. However, some writers claim that they may have been producing copies of glass objects from Egypt. Other archaeological evidence suggests that the first true glass was made in coastal north Syria, Mesopotamia or Egypt. The earliest known glass objects, of the mid 2,000 BCE, were beads, perhaps initially created as the accidental by-products of metal-working (slags) or during the production of faience, a pre-glass vitreous material made by a process similar to glazing. Glass products remained a luxury until the disasters that overtook the late Bronze Age civilizations seemingly brought glass-making to a halt.

Glazing, which derives from the Middle English for 'glass', is a part of a wall or window, made of glass. Glazing also describes the work done by a professional "glazier". Glazing is also less commonly used to describe the insertion of ophthalmic lenses into an eyeglass frame.