Mining is the extraction of valuable geological materials and minerals from the surface of the Earth. Mining is required to obtain most materials that cannot be grown through agricultural processes, or feasibly created artificially in a laboratory or factory. Ores recovered by mining include metals, coal, oil shale, gemstones, limestone, chalk, dimension stone, rock salt, potash, gravel, and clay. The ore must be a rock or mineral that contains valuable constituent, can be extracted or mined and sold for profit. Mining in a wider sense includes extraction of any non-renewable resource such as petroleum, natural gas, or even water.

Coal mining is the process of extracting coal from the ground or from a mine. Coal is valued for its energy content and since the 1880s has been widely used to generate electricity. Steel and cement industries use coal as a fuel for extraction of iron from iron ore and for cement production. In the United Kingdom and South Africa, a coal mine and its structures are a colliery, a coal mine is called a "pit", and above-ground mining structures are referred to as a "pit head". In Australia, "colliery" generally refers to an underground coal mine.

Open-pit mining, also known as open-cast or open-cut mining and in larger contexts mega-mining, is a surface mining technique that extracts rock or minerals from the earth using a pit, sometimes known as a borrow pit.

In mining, tailings or tails are the materials left over after the process of separating the valuable fraction from the uneconomic fraction (gangue) of an ore. Tailings are different from overburden, which is the waste rock or other material that overlies an ore or mineral body and is displaced during mining without being processed.

Mining in the engineering discipline is the extraction of minerals from the ground. Mining engineering is associated with many other disciplines, such as mineral processing, exploration, excavation, geology, metallurgy, geotechnical engineering and surveying. A mining engineer may manage any phase of mining operations, from exploration and discovery of the mineral resources, through feasibility study, mine design, development of plans, production and operations to mine closure.

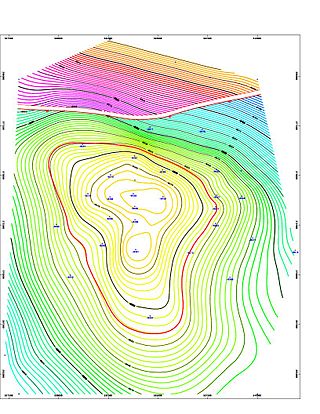

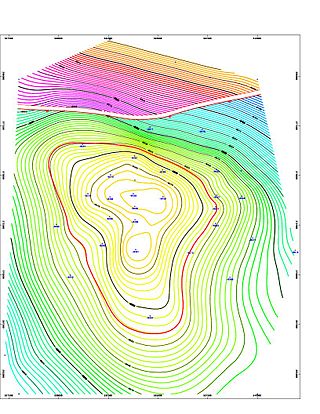

Geologic modelling,geological modelling or geomodelling is the applied science of creating computerized representations of portions of the Earth's crust based on geophysical and geological observations made on and below the Earth surface. A geomodel is the numerical equivalent of a three-dimensional geological map complemented by a description of physical quantities in the domain of interest. Geomodelling is related to the concept of Shared Earth Model; which is a multidisciplinary, interoperable and updatable knowledge base about the subsurface.

Surface mining, including strip mining, open-pit mining and mountaintop removal mining, is a broad category of mining in which soil and rock overlying the mineral deposit are removed, in contrast to underground mining, in which the overlying rock is left in place, and the mineral is removed through shafts or tunnels.

Drift mining is either the mining of an ore deposit by underground methods, or the working of coal seams accessed by adits driven into the surface outcrop of the coal bed. A drift mine is an underground mine in which the entry or access is above water level and generally on the slope of a hill, driven horizontally into the ore seam.

Exploration geophysics is an applied branch of geophysics and economic geology, which uses physical methods at the surface of the Earth, such as seismic, gravitational, magnetic, electrical and electromagnetic, to measure the physical properties of the subsurface, along with the anomalies in those properties. It is most often used to detect or infer the presence and position of economically useful geological deposits, such as ore minerals; fossil fuels and other hydrocarbons; geothermal reservoirs; and groundwater reservoirs. It can also be used to detect the presence of unexploded ordnance.

Tower Colliery was the oldest continuously working deep-coal mine in the United Kingdom, and possibly the world, until its closure in 2008. It was the last mine of its kind to remain in the South Wales Valleys. It was located near the villages of Hirwaun and Rhigos, north of the town of Aberdare in the Cynon Valley of South Wales.

The Somerset Coalfield in northern Somerset, England is an area where coal was mined from the 15th century until 1973. It is part of a larger coalfield which stretched into southern Gloucestershire. The Somerset coalfield stretched from Cromhall in the north to the Mendip Hills in the south, and from Bath in the east to Nailsea in the west, a total area of about 240 square miles (622 km2). Most of the pits on the coalfield were concentrated in the Cam Brook, Wellow Brook and Nettlebridge Valleys and around Radstock and Farrington Gurney. The pits were grouped geographically, with clusters of pits close together working the same coal seams often under the same ownership. Many pits shared the trackways and tramways which connected them to the Somerset Coal Canal or railways for distribution.

Wet Earth Colliery was a coal mine located on the Manchester Coalfield, in Clifton, Greater Manchester. The colliery site is now the location of Clifton Country Park. The colliery has a unique place in British coal mining history; apart from being one of the earliest pits in the country, it is the place where engineer James Brindley made water run uphill.

The South Yorkshire Coalfield is so named from its position within Yorkshire. It covers most of South Yorkshire, West Yorkshire and a small part of North Yorkshire. The exposed coalfield outcrops in the Pennine foothills and dips under Permian rocks in the east. Its most famous coal seam is the Barnsley Bed. Coal has been mined from shallow seams and outcrops since medieval times and possibly earlier.

In the Earth sciences, a palaeochannel, also spelled paleochannel, is a significant length of a river or stream channel which no longer conveys fluvial discharge as part of an active fluvial system. The term palaeochannel is derived from the combination of two words, palaeo or old, and channel; i.e., a palaeochannel is an old channel. Palaeochannels may be preserved either as abandoned surface channels on the surface of river floodplains and terraces or infilled and partially or fully buried by younger sediments. The fill of a palaeochannel and its enclosing sedimentary deposits may consist of unconsolidated, semi-consolidated, or well-cemented sedimentary strata depending on the action of tectonics and diagenesis during their geologic history after deposition. The abandonment of an active fluvial channel and the resulting formation of a palaeochannel can be the result of tectonic processes, geomorphologic processes, anthropogenic activities, climatic changes, or a variable and interrelated combination of these factors.

The Cheadle Coalfield is a coalfield in the United Kingdom. Centred on the town of Cheadle, Staffordshire and its outlying villages it lies to the east of Stoke-on-Trent and the much larger North Staffordshire Coalfield. The area has been mined for many years, with documentary evidence from Croxden Abbey citing coal mining in the 13th century.

Mining in New Zealand began when the Māori quarried rock such as argillite in times prior to European colonisation. Mining by Europeans began in the latter half of the 19th century.

SAG/SDAG Wismut was a uranium mining company in East Germany during the time of the Cold War. It produced a total of 230,400 tonnes of uranium between 1947 and 1990 and made East Germany the fourth largest producer of uranium ore in the world at the time. It was the largest single producer of uranium ore in the entire sphere of control of the USSR. In 1991 after German reunification it was transformed into the Wismut GmbH company, owned by the Federal Republic of Germany, which is now responsible for the restoration and environmental cleanup of the former mining and milling areas. The head office of SDAG Wismut / Wismut GmbH is in Chemnitz-Siegmar.

Bradford Colliery was a coal mine in Bradford, Manchester, England. Although part of the Manchester Coalfield, the seams of the Bradford Coalfield correspond more closely to those of the Oldham Coalfield. The Bradford Coalfield is crossed by a number of fault lines, principally the Bradford Fault, which was reactivated by mining activity in the mid-1960s.

Sohagpur Coalfield is located in Shahdol district in the Indian state of Madhya Pradesh in the basin of the Son River. It is the biggest coalfield in the state of Madhya Pradesh.

Hapton Valley Colliery was a coal mine on the edge of Hapton near Burnley in Lancashire, England. Its first shafts were sunk in the early 1850s and it had a life of almost 130 years, surviving to be the last deep mine operating on the Burnley Coalfield.