In robotics, robot kinematics applies geometry to the study of the movement of multi-degree of freedom kinematic chains that form the structure of robotic systems. [1] [2] The emphasis on geometry means that the links of the robot are modeled as rigid bodies and its joints are assumed to provide pure rotation or translation.

Robot kinematics studies the relationship between the dimensions and connectivity of kinematic chains and the position, velocity and acceleration of each of the links in the robotic system, in order to plan and control movement and to compute actuator forces and torques. The relationship between mass and inertia properties, motion, and the associated forces and torques is studied as part of robot dynamics.

A fundamental tool in robot kinematics is the kinematics equations of the kinematic chains that form the robot. These non-linear equations are used to map the joint parameters to the configuration of the robot system. Kinematics equations are also used in biomechanics of the skeleton and computer animation of articulated characters.

Forward kinematics uses the kinematic equations of a robot to compute the position of the end-effector from specified values for the joint parameters. [3] The reverse process that computes the joint parameters that achieve a specified position of the end-effector is known as inverse kinematics. The dimensions of the robot and its kinematics equations define the volume of space reachable by the robot, known as its workspace.

There are two broad classes of robots and associated kinematics equations: serial manipulators and parallel manipulators. Other types of systems with specialized kinematics equations are air, land, and submersible mobile robots, hyper-redundant, or snake, robots and humanoid robots.

Forward kinematics specifies the joint parameters and computes the configuration of the chain. For serial manipulators this is achieved by direct substitution of the joint parameters into the forward kinematics equations for the serial chain. For parallel manipulators substitution of the joint parameters into the kinematics equations requires solution of the a set of polynomial constraints to determine the set of possible end-effector locations.

Inverse kinematics specifies the end-effector location and computes the associated joint angles. For serial manipulators this requires solution of a set of polynomials obtained from the kinematics equations and yields multiple configurations for the chain. The case of a general 6R serial manipulator (a serial chain with six revolute joints) yields sixteen different inverse kinematics solutions, which are solutions of a sixteenth degree polynomial. For parallel manipulators, the specification of the end-effector location simplifies the kinematics equations, which yields formulas for the joint parameters.

The time derivative of the kinematics equations yields the Jacobian of the robot, which relates the joint rates to the linear and angular velocity of the end-effector. The principle of virtual work shows that the Jacobian also provides a relationship between joint torques and the resultant force and torque applied by the end-effector. Singular configurations of the robot are identified by studying its Jacobian.

The robot Jacobian results in a set of linear equations that relate the joint rates to the six-vector formed from the angular and linear velocity of the end-effector, known as a twist. Specifying the joint rates yields the end-effector twist directly.

The inverse velocity problem seeks the joint rates that provide a specified end-effector twist. This is solved by inverting the Jacobian matrix. It can happen that the robot is in a configuration where the Jacobian does not have an inverse. These are termed singular configurations of the robot.

The principle of virtual work yields a set of linear equations that relate the resultant force-torque six vector, called a wrench, that acts on the end-effector to the joint torques of the robot. If the end-effector wrench is known, then a direct calculation yields the joint torques.

The inverse statics problem seeks the end-effector wrench associated with a given set of joint torques, and requires the inverse of the Jacobian matrix. As in the case of inverse velocity analysis, at singular configurations this problem cannot be solved. However, near singularities small actuator torques result in a large end-effector wrench. Thus near singularity configurations robots have large mechanical advantage.

Robot kinematics also deals with motion planning, singularity avoidance, redundancy , collision avoidance, as well as the kinematic synthesis of robots. [4]

An industrial robot is a robot system used for manufacturing. Industrial robots are automated, programmable and capable of movement on three or more axes.

In classical mechanics, the parameters that define the configuration of a system are called generalized coordinates, and the space defined by these coordinates is called the configuration space of the physical system. It is often the case that these parameters satisfy mathematical constraints, such that the set of actual configurations of the system is a manifold in the space of generalized coordinates. This manifold is called the configuration manifold of the system. Notice that this is a notion of "unrestricted" configuration space, i.e. in which different point particles may occupy the same position. In mathematics, in particular in topology, a notion of "restricted" configuration space is mostly used, in which the diagonals, representing "colliding" particles, are removed.

In computer animation and robotics, inverse kinematics is the mathematical process of calculating the variable joint parameters needed to place the end of a kinematic chain, such as a robot manipulator or animation character's skeleton, in a given position and orientation relative to the start of the chain. Given joint parameters, the position and orientation of the chain's end, e.g. the hand of the character or robot, can typically be calculated directly using multiple applications of trigonometric formulas, a process known as forward kinematics. However, the reverse operation is, in general, much more challenging.

Screw theory is the algebraic calculation of pairs of vectors, also known as dual vectors – such as angular and linear velocity, or forces and moments – that arise in the kinematics and dynamics of rigid bodies.

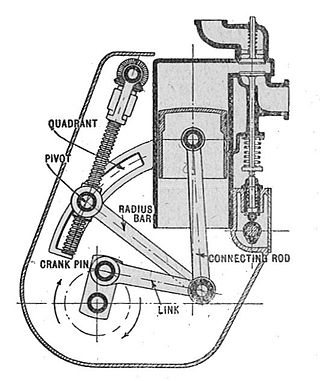

A mechanical linkage is an assembly of systems connected so as to manage forces and movement. The movement of a body, or link, is studied using geometry so the link is considered to be rigid. The connections between links are modeled as providing ideal movement, pure rotation or sliding for example, and are called joints. A linkage modeled as a network of rigid links and ideal joints is called a kinematic chain.

Trajectory optimization is the process of designing a trajectory that minimizes some measure of performance while satisfying a set of constraints. Generally speaking, trajectory optimization is a technique for computing an open-loop solution to an optimal control problem. It is often used for systems where computing the full closed-loop solution is not required, impractical or impossible. If a trajectory optimization problem can be solved at a rate given by the inverse of the Lipschitz constant, then it can be used iteratively to generate a closed-loop solution in the sense of Caratheodory. If only the first step of the trajectory is executed for an infinite-horizon problem, then this is known as Model Predictive Control (MPC).

Inverse dynamics is an inverse problem. It commonly refers to either inverse rigid body dynamics or inverse structural dynamics. Inverse rigid-body dynamics is a method for computing forces and/or moments of force (torques) based on the kinematics (motion) of a body and the body's inertial properties. Typically it uses link-segment models to represent the mechanical behaviour of interconnected segments, such as the limbs of humans or animals or the joint extensions of robots, where given the kinematics of the various parts, inverse dynamics derives the minimum forces and moments responsible for the individual movements. In practice, inverse dynamics computes these internal moments and forces from measurements of the motion of limbs and external forces such as ground reaction forces, under a special set of assumptions.

In engineering, a mechanical singularity is a position or configuration of a mechanism or a machine where the subsequent behaviour cannot be predicted, or the forces or other physical quantities involved become infinite or nondeterministic.

Serial manipulators are the most common industrial robots and they are designed as a series of links connected by motor-actuated joints that extend from a base to an end-effector. Often they have an anthropomorphic arm structure described as having a "shoulder", an "elbow", and a "wrist".

A parallel manipulator is a mechanical system that uses several computer-controlled serial chains to support a single platform, or end-effector. Perhaps, the best known parallel manipulator is formed from six linear actuators that support a movable base for devices such as flight simulators. This device is called a Stewart platform or the Gough-Stewart platform in recognition of the engineers who first designed and used them.

In robot kinematics, forward kinematics refers to the use of the kinematic equations of a robot to compute the position of the end-effector from specified values for the joint parameters.

In mechanical engineering, a kinematic chain is an assembly of rigid bodies connected by joints to provide constrained motion that is the mathematical model for a mechanical system. As the word chain suggests, the rigid bodies, or links, are constrained by their connections to other links. An example is the simple open chain formed by links connected in series, like the usual chain, which is the kinematic model for a typical robot manipulator.

321 kinematic structure is a design method for robotic arms, invented by Donald L. Pieper and used in most commercially produced robotic arms. The inverse kinematics of serial manipulators with six revolute joints, and with three consecutive joints intersecting, can be solved in closed form, i.e. a set of equations can be written that give the joint positions required to place the end of the arm in a particular position and orientation. An arm design that does not follow these design rules typically requires an iterative algorithm to solve the inverse kinematics problem.

In mechatronics engineering, the Denavit–Hartenberg parameters are the four parameters associated with the DH convention for attaching reference frames to the links of a spatial kinematic chain, or robot manipulator.

Open Robotics Automation Virtual Environment (OpenRAVE) provides an environment for testing, developing, and deploying motion planning algorithms in real-world robotics applications. The main focus is on simulation and analysis of kinematic and geometric information related to motion planning. OpenRAVE's stand-alone nature allows it to be easily integrated into existing robotics systems. It provides many command-line tools to work with robots and planners, and the run-time core is small enough to be used inside controllers and bigger frameworks.

In robot kinematics, the manipulability ellipsoid represents the manipulability of a robotic system in a graphical form. Here, the manipulability of a robot arm refers to its ability to alter the position of the end effector based on the joint configuration. A higher manipulability measure signifies a broader range of potential movements in that specific configuration. When the robot is in a singular configuration the manipulability measure diminishes to zero.

Kinematics equations are the constraint equations of a mechanical system such as a robot manipulator that define how input movement at one or more joints specifies the configuration of the device, in order to achieve a task position or end-effector location. Kinematics equations are used to analyze and design articulated systems ranging from four-bar linkages to serial and parallel robots.

The product of exponentials (POE) method is a robotics convention for mapping the links of a spatial kinematic chain. It is an alternative to Denavit–Hartenberg parameterization. While the latter method uses the minimal number of parameters to represent joint motions, the former method has a number of advantages: uniform treatment of prismatic and revolute joints, definition of only two reference frames, and an easy geometric interpretation from the use of screw axes for each joint.

In kinematics, a five-bar linkage is a mechanism with two degrees of freedom that is constructed from five links that are connected together in a closed chain. All links are connected to each other by five joints in series forming a loop. One of the links is the ground or base. This configuration is also called a pantograph, however, it is not to be confused with the parallelogram-copying linkage pantograph.