Related Research Articles

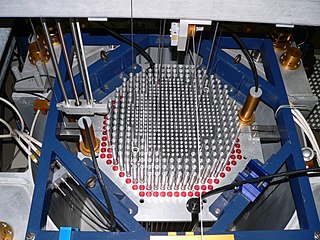

The CANDU is a Canadian pressurized heavy-water reactor design used to generate electric power. The acronym refers to its deuterium oxide moderator and its use of uranium fuel. CANDU reactors were first developed in the late 1950s and 1960s by a partnership between Atomic Energy of Canada Limited (AECL), the Hydro-Electric Power Commission of Ontario, Canadian General Electric, and other companies.

A nuclear reactor is a device used to initiate and control a fission nuclear chain reaction or nuclear fusion reactions. Nuclear reactors are used at nuclear power plants for electricity generation and in nuclear marine propulsion. Heat from nuclear fission is passed to a working fluid, which in turn runs through steam turbines. These either drive a ship's propellers or turn electrical generators' shafts. Nuclear generated steam in principle can be used for industrial process heat or for district heating. Some reactors are used to produce isotopes for medical and industrial use, or for production of weapons-grade plutonium. As of 2022, the International Atomic Energy Agency reports there are 422 nuclear power reactors and 223 nuclear research reactors in operation around the world.

A pressurized water reactor (PWR) is a type of light-water nuclear reactor. PWRs constitute the large majority of the world's nuclear power plants. In a PWR, the primary coolant (water) is pumped under high pressure to the reactor core where it is heated by the energy released by the fission of atoms. The heated, high pressure water then flows to a steam generator, where it transfers its thermal energy to lower pressure water of a secondary system where steam is generated. The steam then drives turbines, which spin an electric generator. In contrast to a boiling water reactor (BWR), pressure in the primary coolant loop prevents the water from boiling within the reactor. All light-water reactors use ordinary water as both coolant and neutron moderator. Most use anywhere from two to four vertically mounted steam generators; VVER reactors use horizontal steam generators.

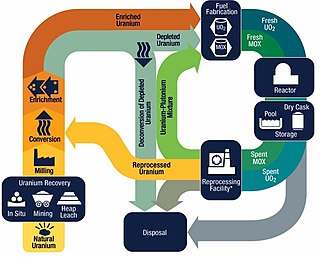

The nuclear fuel cycle, also called nuclear fuel chain, is the progression of nuclear fuel through a series of differing stages. It consists of steps in the front end, which are the preparation of the fuel, steps in the service period in which the fuel is used during reactor operation, and steps in the back end, which are necessary to safely manage, contain, and either reprocess or dispose of spent nuclear fuel. If spent fuel is not reprocessed, the fuel cycle is referred to as an open fuel cycle ; if the spent fuel is reprocessed, it is referred to as a closed fuel cycle.

A breeder reactor is a nuclear reactor that generates more fissile material than it consumes. These reactors can be fueled with more-commonly available isotopes of uranium and thorium, such as uranium-238 and thorium-232, as opposed to the rare uranium-235 which is used in conventional reactors. These materials are called fertile materials since they can be bred into fuel by these breeder reactors.

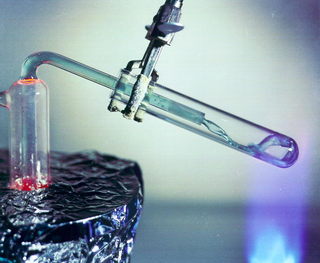

A molten salt reactor (MSR) is a class of nuclear fission reactor in which the primary nuclear reactor coolant and/or the fuel is a mixture of molten salt with a fissionable material.

The Bhabha Atomic Research Centre (BARC) is India's premier nuclear research facility, headquartered in Trombay, Mumbai, Maharashtra, India. It was founded by Homi Jehangir Bhabha as the Atomic Energy Establishment, Trombay (AEET) in January 1954 as a multidisciplinary research program essential for India's nuclear program. It operates under the Department of Atomic Energy (DAE), which is directly overseen by the Prime Minister of India.

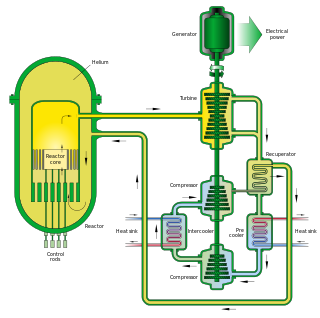

The gas-cooled fast reactor (GFR) system is a nuclear reactor design which is currently in development. Classed as a Generation IV reactor, it features a fast-neutron spectrum and closed fuel cycle for efficient conversion of fertile uranium and management of actinides. The reference reactor design is a helium-cooled system operating with an outlet temperature of 850 °C (1,560 °F) using a direct Brayton closed-cycle gas turbine for high thermal efficiency. Several fuel forms are being considered for their potential to operate at very high temperatures and to ensure an excellent retention of fission products: composite ceramic fuel, advanced fuel particles, or ceramic clad elements of actinide compounds. Core configurations are being considered based on pin- or plate-based fuel assemblies or prismatic blocks, which allows for better coolant circulation than traditional fuel assemblies.

The Prototype Fast Breeder Reactor (PFBR) is a 500 MWe fast breeder nuclear reactor presently being constructed at Kalpakkam, India. The Indira Gandhi Centre for Atomic Research (IGCAR) is responsible for the design of this reactor. The facility builds on the decades of experience gained from operating the lower power Fast Breeder Test Reactor (FBTR). At first, the reactor's construction was supposed to be completed in September 2010, but there were several delays. The Prototype Fast Breeder Reactor is scheduled to be put into service in December 2024, which is more than 20 years after construction began and 14 years after the original commissioning date, as of December 2023. The project's cost has doubled from ₹3,500 crore to ₹7,700 crore due to the multiple delays.The project currently holds an infamous record of being the longest under-construction nuclear reactor project in the world.

Nuclear power is the fifth-largest source of electricity in India after coal, gas, hydroelectricity and wind power. As of November 2020, India has 22 nuclear reactors in operation in 8 nuclear power plants, with a total installed capacity of 7,380 MW. Nuclear power produced a total of 43 TWh in 2020–21, contributing 3.11% of total power generation in India. 10 more reactors are under construction with a combined generation capacity of 8,000 MW.

The liquid fluoride thorium reactor is a type of molten salt reactor. LFTRs use the thorium fuel cycle with a fluoride-based molten (liquid) salt for fuel. In a typical design, the liquid is pumped between a critical core and an external heat exchanger where the heat is transferred to a nonradioactive secondary salt. The secondary salt then transfers its heat to a steam turbine or closed-cycle gas turbine.

India's three-stage nuclear power programme was formulated by Homi Bhabha, the well-known physicist, in the 1950s to secure the country's long term energy independence, through the use of uranium and thorium reserves found in the monazite sands of coastal regions of South India. The ultimate focus of the programme is on enabling the thorium reserves of India to be utilised in meeting the country's energy requirements. Thorium is particularly attractive for India, as India has only around 1–2% of the global uranium reserves, but one of the largest shares of global thorium reserves at about 25% of the world's known thorium reserves. However, thorium is more difficult to use than uranium as a fuel because it requires breeding, and global uranium prices remain low enough that breeding is not cost effective.

The Energy Multiplier Module is a nuclear fission power reactor under development by General Atomics. It is a fast-neutron version of the Gas Turbine Modular Helium Reactor (GT-MHR) and is capable of converting spent nuclear fuel into electricity and industrial process heat.

A pressurized heavy-water reactor (PHWR) is a nuclear reactor that uses heavy water (deuterium oxide D2O) as its coolant and neutron moderator. PHWRs frequently use natural uranium as fuel, but sometimes also use very low enriched uranium. The heavy water coolant is kept under pressure to avoid boiling, allowing it to reach higher temperature (mostly) without forming steam bubbles, exactly as for a pressurized water reactor. While heavy water is very expensive to isolate from ordinary water (often referred to as light water in contrast to heavy water), its low absorption of neutrons greatly increases the neutron economy of the reactor, avoiding the need for enriched fuel. The high cost of the heavy water is offset by the lowered cost of using natural uranium and/or alternative fuel cycles. As of the beginning of 2001, 31 PHWRs were in operation, having a total capacity of 16.5 GW(e), representing roughly 7.76% by number and 4.7% by generating capacity of all current operating reactors.

Ratan Kumar Sinha, is an Indian nuclear scientist and mechanical engineer. He had served as the Secretary to the Government of India, Department of Atomic Energy (DAE) and Chairman of the Atomic Energy Commission (AEC), Government of India from April 2012 to October 2015. Prior to that, Ratan Kumar Sinha had served as Director of Bhabha Atomic Research Centre (BARC), Mumbai from May 2010 to June 2012. During the four decades of his career, Ratan Kumar Sinha held several important positions related to design & development of nuclear reactors for the Indian nuclear programme. He has been actively involved in the development of the advanced heavy water reactor (AHWR) and Compact High Temperature Reactor (CHTR), two of the highly acknowledged technological innovations which are suitable for large scale deployment of nuclear power, particularly in India.

Thorium-based nuclear power generation is fueled primarily by the nuclear fission of the isotope uranium-233 produced from the fertile element thorium. A thorium fuel cycle can offer several potential advantages over a uranium fuel cycle—including the much greater abundance of thorium found on Earth, superior physical and nuclear fuel properties, and reduced nuclear waste production. One advantage of thorium fuel is its low weaponization potential; it is difficult to weaponize the uranium-233/232 and plutonium-238 isotopes that are largely consumed in thorium reactors.

The IPHWR-700 is an Indian pressurized heavy-water reactor designed by the NPCIL. It is a Generation III reactor developed from earlier CANDU based 220 MW and 540 MW designs. It can generate 700 MW of electricity. Currently there are 5 units under construction and 10 more units planned, at a cost of ₹1.05 lakh crore (US$13 billion).

The IPHWR-220 is an Indian pressurized heavy-water reactor designed by the Bhabha Atomic Research Centre. It is a Generation II reactor developed from earlier CANDU based RAPS-1 and RAPS-2 reactors built at Rawatbhata, Rajasthan. It can generate 220 MW of electricity. Currently, there are 14 units operational at various locations in India. It is sometimes referred to as an small modular reactor due to its modularization.

The IPHWR is a class of Indian pressurized heavy-water reactors designed by the Bhabha Atomic Research Centre. The baseline 220 MWe design was developed from the CANDU based RAPS-1 and RAPS-2 reactors built at Rawatbhata, Rajasthan. Later the design was based on VVER technology which was scaled to 540 MW and 700 MW designs. Currently there are 17 units of various types operational at various locations in India.

The Indian Pressurized Water Reactor-900 (IPWR-900) is a class of pressurized water reactors being designed by Bhabha Atomic Research Centre (BARC) in partnership with Nuclear Power Corporation of India Limited to supplement the Indian three-stage nuclear power programme

References

- ↑ "Archived copy". Archived from the original on 2014-01-27. Retrieved 2014-03-31.

{{cite web}}: CS1 maint: archived copy as title (link) - ↑ "India all set to tap thorium resources". Dec 2012. Archived from the original on 2012-05-13. Retrieved 2012-05-11.

- ↑ "REPROCESSING GROUP". 18 July 2014. Archived from the original on 18 July 2014. Retrieved 9 May 2023.

- 1 2 3 4 Advanced Heavy Water Reactor (AHWR) BARC (Bhabha Atomic Research Centre) (India) (PDF) (Report). International Atomic Energy Agency. 2013. Archived from the original (PDF) on 19 April 2014.

- ↑ "India designs new atomic reactor for thorium utilisation". The Indian Express. Mumbai. 16 September 2009.

- ↑ "Thorium". Archived from the original on 16 February 2013. Retrieved 9 May 2023.

- ↑ Shimjith, S.R.; Tiwari, A.P.; Bandyopadhyay, B.; Patil, R.K. (July 2011). "Spatial stabilization of Advanced Heavy Water Reactor". Annals of Nuclear Energy. 38 (7): 1545–1558. doi:10.1016/j.anucene.2011.03.008.

- ↑ "DAE AHWR Report". Department of Atomic Energy. Archived from the original on 21 October 2018. Retrieved 14 May 2023.

- ↑ "Establishment of Atomic Power Stations in the Country. Aug 2013". Archived from the original on 2013-09-25. Retrieved 2013-08-29.

- ↑ "Fuel for India's nuclear ambitions". Nuclear Engineering International. 7 April 2017. Archived from the original on 12 April 2017. Retrieved 12 April 2017.

- ↑ Vijayan, P K; Kamble, M T; Nayak, A K; Vaze, K K; Sinha, R K (October 2013). "Safety features in nuclear power plants to eliminate the need of emergency planning in public domain". Sādhanā. 38 (5): 925–943. doi: 10.1007/s12046-013-0178-5 .

- ↑ "2013 AHWR Design Description (India) ARIS" (PDF). International Atomic Energy Agency. 11 July 2013. Archived (PDF) from the original on 2021-09-27. Retrieved 2021-03-21.

- ↑ Kumar, Arvind; Srivenkatesan, R; Sinha, R K (11 July 2013). "On the Physics Design of Advanced Heavy Water Reactor (AHWR)" (PDF). Reactor Design Development Group, Bhabha Atomic Research Centre. Archived (PDF) from the original on 2021-04-11. Retrieved 2021-03-21.