Related Research Articles

A flange is a protruded ridge, lip or rim, either external or internal, that serves to increase strength ; for easy attachment/transfer of contact force with another object ; or for stabilizing and guiding the movements of a machine or its parts. Flanges are often attached using bolts in the pattern of a bolt circle.

An inspection is, most generally, an organized examination or formal evaluation exercise. In engineering activities inspection involves the measurements, tests, and gauges applied to certain characteristics in regard to an object or activity. The results are usually compared to specified requirements and standards for determining whether the item or activity is in line with these targets, often with a Standard Inspection Procedure in place to ensure consistent checking. Inspections are usually non-destructive.

The American Society of Mechanical Engineers (ASME) is an American professional association that, in its own words, "promotes the art, science, and practice of multidisciplinary engineering and allied sciences around the globe" via "continuing education, training and professional development, codes and standards, research, conferences and publications, government relations, and other forms of outreach." ASME is thus an engineering society, a standards organization, a research and development organization, an advocacy organization, a provider of training and education, and a nonprofit organization. Founded as an engineering society focused on mechanical engineering in North America, ASME is today multidisciplinary and global.

A pressure vessel is a container designed to hold gases or liquids at a pressure substantially different from the ambient pressure.

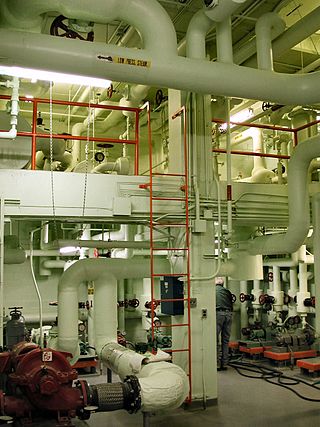

Within industry, piping is a system of pipes used to convey fluids from one location to another. The engineering discipline of piping design studies the efficient transport of fluid.

A bioprocess is a specific process that uses complete living cells or their components to obtain desired products.

The Pressure Equipment Directive (PED) 2014/68/EU of the EU sets out the standards for the design and fabrication of pressure equipment generally over one liter in volume and having a maximum pressure more than 0.5 bar gauge. It also sets the administrative procedures requirements for the "conformity assessment" of pressure equipment, for the free placing on the European market without local legislative barriers. It has been mandatory throughout the EU since 30 May 2002, with 2014 revision fully effective as of 19 July 2016. The standards and regulations regarding pressure vessels and boiler safety are also very close to the US standards defined by the American Society of Mechanical Engineers (ASME). This enables most international inspection agencies to provide both verification and certification services to assess compliance to the different pressure equipment directives. From the pressure vessel manufactures PED does not generally require a prior manufacturing permit/certificate/stamp as ASME does.

Welder certification, is a process which examines and documents a welder's capability to create welds of acceptable quality following a well defined welding procedure.

A pipe is a tubular section or hollow cylinder, usually but not necessarily of circular cross-section, used mainly to convey substances which can flow — liquids and gases (fluids), slurries, powders and masses of small solids. It can also be used for structural applications; hollow pipe is far stiffer per unit weight than solid members.

Clean-in-place (CIP) is an automated method of cleaning the interior surfaces of pipes, vessels, equipment, filters and associated fittings, without major disassembly. CIP is commonly used for equipment such as piping, tanks, and fillers. CIP employs turbulent flow through piping, and/or spray balls for tanks or vessels. In some cases, CIP can also be accomplished with fill, soak and agitate.

Designated as an American National Standard, the Uniform Swimming Pool, Spa and Hot Tub Code (USPSHTC) is a model code developed by the International Association of Plumbing and Mechanical Officials (IAPMO) to govern the installation and inspection of plumbing systems associated with swimming pools, spas and hot tubs as a means of promoting the public's health, safety and welfare.

The ASME Boiler & Pressure Vessel Code (BPVC) is an American Society of Mechanical Engineers (ASME) standard that regulates the design and construction of boilers and pressure vessels. The document is written and maintained by volunteers chosen for their technical expertise. The ASME works as an accreditation body and entitles independent third parties to inspect and ensure compliance to the BPVC.

ASME NQA-1 is an industry consensus standard created and maintained by the American Society of Mechanical Engineers (ASME). The latest edition was issued on June 30, 2022 (NQA-1-2022). However, the most commonly used version in the supply chain is NQA-1-2008 with the NQA-1a-2009 addendum. Any organization submitting an application for a new design are using the NQA-1-2015 edition. This is the case because these are the versions endorsed by the NRC.

A single-use bioreactor or disposable bioreactor is a bioreactor with a disposable bag instead of a culture vessel. Typically, this refers to a bioreactor in which the lining in contact with the cell culture will be plastic, and this lining is encased within a more permanent structure. Commercial single-use bioreactors have been available since the end of the 1990s and are now made by several well-known producers.

The Uniform Mechanical Code (UMC) is a model code developed by the International Association of Plumbing and Mechanical Officials (IAPMO) to govern the installation, inspection and maintenance of HVAC and refrigeration systems. It is designated as an American National Standard.

ASME is a non-profit organization that continues to develop and maintains nearly 600 codes and standards in a wide range of disciplines. Some of which includes the Boiler and Pressure Vessel Code (BPVC), Elevators and Escalators, Piping and Pipelines, Bioprocessing Equipment (BPE), Nuclear Facility Applications (NQA), Process Performance Test Codes (PTC), and Valves, Flanges, Fittings and Gaskets (B16).

In the process industry, chemical industry, manufacturing industry, and other commercial and industrial contexts, pipe marking is used to identify the contents, properties and flow direction of fluids in piping. It is typically carried out by marking piping through labels and color codes. Pipe marking helps personnel and fire response teams identify the correct pipes for operational, maintenance or emergency response purposes.

Post weld heat treatment (PWHT) is a controlled process in which a material that has been welded is reheated to a temperature below its lower critical transformation temperature, and then it is held at that temperature for a specified amount of time. It is often referred to as being any heat treatment performed after welding; however, within the oil, gas, petrochemical and nuclear industries, it has a specific meaning. Industry codes, such as the ASME Pressure Vessel and Piping Codes, often require mandatory performance of PWHT on certain materials to ensure a safe design with optimal mechanical and metallurgical properties.

API Standard 682, titled "Pumps - Shaft Sealing Systems for Centrifugal and Rotary Pumps," is the American Petroleum Institute (API) standard for end-face mechanical seals. The purpose of API 682 is to assist in the selection and operation of end face mechanical seals in centrifugal pumps. It is based on the combined knowledge and experience of seal manufacturers, engineering companies, and end users. API 682 is primarily intended for use in the petroleum, natural gas and chemical industries, but is often referenced for other types of equipment and industries.

Piping systems in U.S. nuclear power plants that are relied on for the safe shutdown of the plant are typically constructed to Section III of the American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel (B&PV) Code. The materials allowed by the ASME B&PV Code have been historically limited to metallic materials only. Due to the success of high density polyethylene (HDPE) in other industries, nuclear power plants in the U.S. have expressed interest in using HDPE piping in ASME B&PV Code applications. In 2008, the first U.S. nuclear power plant was approved by the United States Nuclear Regulatory Commission to install HDPE in an ASME B&PV Code safety-related system. Since then, the rules for using HDPE have been integrated into the 2015 Edition and 2017 Edition of the ASME B&PV Code. The NRC approved of the 2015 and 2017 Editions in 2020.

References

- ↑ "Internet Archive". Wayback Machine. April 19, 2011. Archived from the original on 2011-04-19.

- ↑ "California Health and Safety Code Section 18909".

- ↑ "California Building Code, Part 1, Chapter 1, Section 1.1.6".

Huitt, Bill. (2016). Bioprocessing Piping and Equipment Design: A Companion Guide for the ASME BPE Standard (Wiley-ASME Press Series) 1st Edition. Wiley-ASME Press Series. https://www.amazon.com/Bioprocessing-Piping-Equipment-Design-Wiley-ASME/dp/1119284236