The ARECC process

The implementation of ARECC (Figure 1) involves conducting risk assessment and applying risk management. The ARECC graphic appears as the first illustration in the authoritative industrial hygiene reference book A Strategy for Assessing and Managing Occupational Exposures. [4] The Occupational Exposure Assessment Body of Knowledge (BoK) documents developed by the American Industrial Hygiene Association [5] [6] provide an organized summary of the collective knowledge and skills necessary for persons to use the ARECC process in conducting occupational exposure assessments. AIHA has also developed a Technical Framework on Susceptible Worker Protection [7] which includes the application of ARECC to foster awareness, understanding, and the ability to apply knowledge about the protection of susceptible workers. AIHA is using the BoKs to establish a framework for the development of education programs and knowledge/skill assessment tools, and for the improvement of the state of professional IH knowledge.

Risk assessment

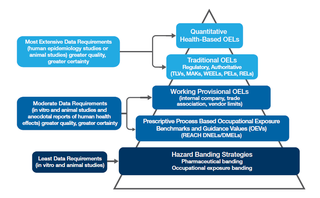

During the risk assessment phase, the details of existing or potential hazards and exposures to populations of workers and members of their communities are assessed to characterize risks. The hazard identification/dose-response/exposure assessment/risk assessment approach mirrors the process that was formulated by the National Academy of Sciences / National Research Council. [8] [9] Schulte et al. noted the interrelated criteria of hazard identification/exposure assessment/risk assessment/risk management/fostering of benefits for responsible development of nanotechnology. [10] Schulte et al. also noted significant examples of progress in the fields of toxicology, metrology, exposure assessment, engineering controls and personal protective equipment (PPE), risk assessment, risk management, medical surveillance, and epidemiology for protection of nanotechnology workers. [11]

As emphasized in Figure 1, strong interactions are needed between the hazard assessment, exposure assessment, and population assessment activities. [12] Exposure- and population-informed hazard assessment ensures that realistic information about actual workplace exposure compositions, concentrations, and conditions are factored into any laboratory-based studies of health effects that are conducted. Hazard- and population-informed exposure assessment ensures that the relevant exposures are assessed in the appropriate locations and at the appropriate times. Hazard- and exposure-informed population assessment ensures that relevant and reliable susceptibility information for the exposed population is collected for assessment against, and refinement of, the hazard criteria. Identifying and defining dose-response relationships for exposures to hazards allows for the establishment of occupational exposure limits, hazard criteria for concerns such as exposures to skin, and the grouping of materials into hazard bands that can be similarly controlled.

Risk management

The risk management portion of the ARECC framework and process emphasizes leadership commitment to the safety and health mission and application of the hierarchy of controls. Commitment includes confirming that all ARECC process steps are being followed and that protection of safety, health, well-being, and productivity is being achieved.

The hierarchy of hazard controls is an integral component of the application of ARECC. The hierarchy is traditionally depicted as a vertical listing of hazard control and exposure control options in descending order of priority, beginning at the top with elimination of the hazard as the most effective control, followed by substitution of a less hazardous option, followed by engineering controls to prevent exposures, followed by administrative and work practice controls, and concluding with use of personal protective equipment as the least effective control at the bottom.

Figure 2 depicts an alternative depiction of the hierarchy as a pyramid of interactive control elements. [13] The components of hazard and exposure control depicted in the pyramid formulation of the hierarchy of control are

- Elimination of the presence or magnitude of the hazard (not always possible if the material or condition is essential to the activity objectives but sometimes possible in the case of objectives that can be achieved by methods such as computer simulation),

- Substitution of a less hazardous material or procedure (sometimes possible, such as through the use of materially similar surrogates or the use of less dispersible materials or less energetic processes. A "regrettable substitution" may result if assumptions about the risk-reduction advantages of the substitution turned out to be wrong. Recent examples of regrettable substitution are the substitution of bisphenol S for bisphenol A in plastics, and the substitution of alpha-diketone for diacetyl in butter flavorings. [14]

- Modification of the material or procedure to reduce hazards or exposures (sometimes considered a subset of the substitution option but explicitly considered here to mean that the efficacy of the modification for the situation at hand must be confirmed by the user),

- Engineering controls to prevent exposures (includes a variety of physical containment and ventilation strategies),

- Warnings to indicate the need for and status of control (explicitly considered in the pyramid formulation to be a distinct hierarchy option to clarity the details of any warnings being used and to emphasize the growing capabilities and availability of real time sensors and monitors; whereas in other systems, warnings are sometimes considered part of engineered controls and sometimes part of administrative controls),

- Administrative and work procedures to prevent exposures and confirm protection (an approach that relies highly on training and compliance), and finally, as the last barrier to exposure,

- Personal protective equipment (including respiratory protection).

Figure 3 illustrates how the pyramid formulation of the interrelated elements of the hierarchy of control can be used to provide retrospective, contemporaneous, or prospective insights about the sustainability and levels of risks associated with work activities that involve different combinations of hazards, exposures, controls, and resulting risks. For example, elimination of a hazard is considered to be a highly sustainable strategy, and if a hazard was or is thought to have been eliminated from a process, then initial evaluations can focus on confirmation of material inventories and process knowledge. Similarly, control situations that rely heavily on engineered controls, warnings, work practices, or use of PPE are less sustainable and involve greater risks, and risk management evaluations can focus on confirmation of whether those controls were actually in place and properly applied.

In addition, other hazards may also be present such as heat stress, slips trips and falls, struck-by injuries, toxic metals, toxic gases, electrical shock, lasers, shift work and fatigue. If multiple hazards are present in a work activity, the status of the hierarchy of controls can be assessed for each hazard, and a worst-first, all-hazards approach can be used to prioritize actions to ensure protection from risks. Ideally, as recommended in the American National Standard for Prevention through Design [15] the hierarchy will be used to guide the design of work in a manner that will prevent the presence of hazards, exposures, and resulting risks.