A bulletproof vest, also known as a ballistic vest or a bullet-resistant vest, is an item of body armour that helps absorb the impact and reduce or stop penetration to the torso by firearm-fired projectiles and fragmentation from explosions. The vest may come in a soft form, as worn by many police officers, prison officers, security guards, and some private citizens, used to protect against stabbing attacks or light projectiles, or hard form, using metallic or para-aramid components. Soldiers and police tactical units wear hard armour, either in conjunction with soft armour or alone, to protect against rifle ammunition or fragmentation.

In mechanics and physics, shock is a sudden acceleration caused, for example, by impact, drop, kick, earthquake, or explosion. Shock is a transient physical excitation.

Airsoft, also known as survival game in Japan where it was popular, is a team-based shooting game in which participants eliminate opposing players out of play by shooting them with spherical plastic projectiles shot from airsoft guns.

Sunglasses or sun glasses are a form of protective eyewear designed primarily to prevent bright sunlight and high-energy visible light from damaging or discomforting the eyes. They can sometimes also function as a visual aid, as variously termed spectacles or glasses exist, featuring lenses that are colored, polarized or darkened. In the early 20th century, they were also known as sun cheaters.

Polycarbonates (PC) are a group of thermoplastic polymers containing carbonate groups in their chemical structures. Polycarbonates used in engineering are strong, tough materials, and some grades are optically transparent. They are easily worked, molded, and thermoformed. Because of these properties, polycarbonates find many applications. Polycarbonates do not have a unique resin identification code (RIC) and are identified as "Other", 7 on the RIC list. Products made from polycarbonate can contain the precursor monomer bisphenol A (BPA).

Goggles, or safety glasses, are forms of protective eyewear that usually enclose or protect the area surrounding the eye in order to prevent particulates, water or chemicals from striking the eyes. They are used in chemistry laboratories and in woodworking. They are often used in snow sports as well, and in swimming. Goggles are often worn when using power tools such as drills or chainsaws to prevent flying particles from damaging the eyes. Many types of goggles are available as prescription goggles for those with vision problems.

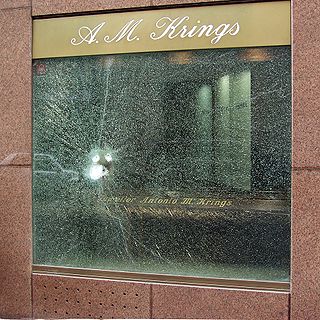

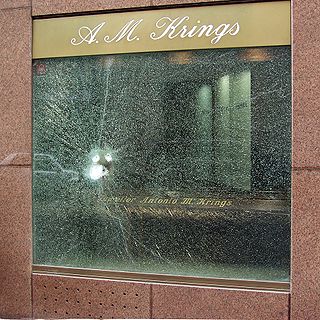

Bulletproof glass, ballistic glass, transparent armor, or bullet-resistant glass is a strong and optically transparent material that is particularly resistant to penetration by projectiles. Like any other material, it is not completely impenetrable. It is usually made from a combination of two or more types of glass, one hard and one soft. The softer layer makes the glass more elastic, so that it can flex instead of shatter. The index of refraction for all of the glasses used in the bulletproof layers must be almost the same to keep the glass transparent and allow a clear, undistorted view through the glass. Bulletproof glass varies in thickness from 3⁄4 to 3+1⁄2 inches.

Military vehicles are commonly armoured to withstand the impact of shrapnel, bullets, shells, rockets, and missiles, protecting the personnel inside from enemy fire. Such vehicles include armoured fighting vehicles like tanks, aircraft, and ships.

Body armor, personal armor, armored suit (armoured) or coat of armor, among others, is armor for a person's body: protective clothing or close-fitting hands-free shields designed to absorb or deflect physical attacks. Historically used to protect military personnel, today it is also used by various types of police, private security guards, or bodyguards, and occasionally ordinary citizens. Today there are two main types: regular non-plated body armor for moderate to substantial protection, and hard-plate reinforced body armor for maximum protection, such as used by combatants.

Eye protection is protective gear for the eyes, and sometimes face, designed to reduce the risk of injury. Examples of risks requiring eye protection can include: impact from particles or debris, light or radiation, wind blast, heat, sea spray or impact from some type of ball or puck used in sports.

The Small Arms Protective Insert (SAPI) is a ceramic ballistic plate used by the United States Armed Forces. It was first used in the Ranger Body Armor and Interceptor Body Armor, both are ballistic vests. It is now also used in the Improved Outer Tactical Vest as well as the Modular Tactical Vest, in addition to commercially available "plate carriers". The Kevlar Interceptor vest itself is designed to stop projectiles up to and including 9×19mm Parabellum submachine gun rounds, in addition to fragmentation. To protect against higher-velocity rifle rounds, SAPI plates are needed.

A face shield, an item of personal protective equipment (PPE), aims to protect the wearer's entire face from hazards such as flying objects and road debris, chemical splashes, or potentially infectious materials. Depending on the type used, a face shield may protect its wearer from a physical hazard, chemical splashes, or biological hazards.

EN 207 is a European norm for laser safety eyewear. Any laser eye protection sold within the European Community must be certified and labeled with the CE mark. According to this standard, laser safety glasses should not only absorb laser light of a given wavelength, but they should also be able to withstand a direct hit from the laser without breaking or melting, both the filter and the frame. In this respect, the European norm is more strict than the American norm that only regulates the required optical density. More precisely, the safety glasses should be able to withstand a continuous wave laser for 5 seconds, or 50 pulses for a pulsed laser.

Aviator sunglasses are a style of sunglasses that was developed by a group of American firms. The original Bausch & Lomb design is now commercially marketed as Ray-Ban Aviators, although other manufacturers also produce aviator-style sunglasses.

A welding helmet is a type of personal protective equipment used in performing certain types of welding to protect the eyes, face, and neck from flash burn, sparks, infrared and ultraviolet light, and intense heat. The modern welding helmet used today was first introduced in 1937 by Willson Products.

Laminated glass is a type of safety glass consisting of two or more layers of glass with one or more thin polymer interlayers between them which prevent the glass from breaking into large sharp pieces. Breaking produces a characteristic "spider web" cracking pattern when the impact is not enough to completely pierce the glass.

The Improved Outer Tactical Vest (IOTV) is an enhanced version of, and a replacement for, the older Outer Tactical Vest (OTV) component of the Interceptor Multi-Threat Body Armor System, as fielded by the United States Army beginning in the mid-2000s. The IOTV is compatible with the Deltoid and Axillary Protector System (DAPS) components, ESAPI, Enhanced Side Ballistic Inserts (ESBI), as well as the OTV's groin protector. It has a flame-resistant standalone shirt, the Army Combat Shirt (ACS), designed specifically for use with the IOTV.

The Advanced Bomb Suit (ABS) is a full body bomb suit designed to protect explosive ordnance disposal (EOD) soldiers from threats associated with improvised explosive devices, including those related to fragmentation, blast overpressure, impact, heat, and flame. Manufactured by Med-Eng, the ABS uses new material technology and design to improve protection, comfort, and ergonomics. The suit is constructed from Kevlar with an outer anti-static cover of 50/50 Nomex/Kevlar and comprises a jacket, crotchless trousers, groin cup, and rigid ballistic panels. To minimize weight and maximize flexibility, protection is provided at various levels, specific to body regions, based on susceptibility to wounds. The suit does not provide gloves to the operator so that maximum ability on the hands is present.

The Authorized Protective Eyewear List (APEL) is a list of protective eyewear tested and approved by the U.S. Military for use by its soldiers. The APEL includes spectacles and goggles optimized for different situations.