Related Research Articles

A turboprop is a turbine engine that drives an aircraft propeller.

A turbofan or fanjet is a type of airbreathing jet engine that is widely used in aircraft propulsion. The word "turbofan" is a combination of references to the preceding generation engine technology of the turbojet and the additional fan stage. It consists of a gas turbine engine which achieves mechanical energy from combustion, and a ducted fan that uses the mechanical energy from the gas turbine to force air rearwards. Thus, whereas all the air taken in by a turbojet passes through the combustion chamber and turbines, in a turbofan some of that air bypasses these components. A turbofan thus can be thought of as a turbojet being used to drive a ducted fan, with both of these contributing to the thrust.

The turbojet is an airbreathing jet engine which is typically used in aircraft. It consists of a gas turbine with a propelling nozzle. The gas turbine has an air inlet which includes inlet guide vanes, a compressor, a combustion chamber, and a turbine. The compressed air from the compressor is heated by burning fuel in the combustion chamber and then allowed to expand through the turbine. The turbine exhaust is then expanded in the propelling nozzle where it is accelerated to high speed to provide thrust. Two engineers, Frank Whittle in the United Kingdom and Hans von Ohain in Germany, developed the concept independently into practical engines during the late 1930s.

The Theseus was the Bristol Aeroplane Company's first attempt at a gas-turbine engine design. A turboprop delivering just over 2,000 hp (1,500 kW) was chosen rather than compete with companies that were already developing turbojets. A heat exchanger to transfer waste heat from the exhaust to the compressor exit was necessary to meet a requirement for a fuel consumption comparable to a piston engine. However, the heat exchanger was abandoned after tests showed that it had a high pressure loss and only produced a fuel saving of 8%. Furthermore overall performance was reduced

The Bristol Proteus was the Bristol Engine Company's first mass-produced gas turbine engine design, a turboprop that delivered just over 4,000 hp (3,000 kW). The Proteus was a reverse-flow gas turbine. Because the second turbine drove no compressor stages, but only the propeller, this engine was classified as a free-turbine. It powered the Bristol Britannia airliner, small naval patrol craft, hovercraft and electrical generating sets. It was also used to power a land-speed record car, the Bluebird-Proteus CN7. After the merger of Bristol with Armstrong Siddeley the engine became the Bristol Siddeley Proteus, and later the Rolls-Royce Proteus. The Proteus was to have been superseded by the Bristol Orion which would have given a Britannia a 75% increase in power for cruising faster.

The Rolls-Royce Olympus was the world's second two-spool axial-flow turbojet aircraft engine design, first run in May 1950 and preceded only by the Pratt & Whitney J57, first-run in January 1950. It is best known as the powerplant of the Avro Vulcan and later models in the Concorde SST.

The Pratt & Whitney J57 is an axial-flow turbojet engine developed by Pratt & Whitney in the early 1950s. The J57 was the first 10,000 lbf (45 kN) thrust class engine in the United States. It is a single spool engine

The General Electric/Allison J35 was the United States Air Force's first axial-flow compressor jet engine. Originally developed by General Electric in parallel with the Whittle-based centrifugal-flow J33, the J35 was a fairly simple turbojet, consisting of an eleven-stage axial-flow compressor and a single-stage turbine. With the afterburner, which most models carried, it produced a thrust of 7,400 lbf (33 kN).

The Rolls-Royce RB.37 Derwent is a 1940s British centrifugal compressor turbojet engine, the second Rolls-Royce jet engine to enter production. It was an improved version of the Rolls-Royce Welland, which itself was a renamed version of Frank Whittle's Power Jets W.2B. Rolls-Royce inherited the Derwent design from Rover when they took over their jet engine development in 1943.

The Rolls-Royce RB.39 Clyde was Rolls-Royce's first purpose-designed turboprop engine and the first turboprop engine to pass its civil and military type-tests.

The Metropolitan-Vickers F.2 is an early turbojet engine and the first British design to be based on an axial-flow compressor. It was an extremely advanced design for the era, using a nine-stage axial compressor, annular combustor, and a two-stage turbine.

An axial compressor is a gas compressor that can continuously pressurize gases. It is a rotating, airfoil-based compressor in which the gas or working fluid principally flows parallel to the axis of rotation, or axially. This differs from other rotating compressors such as centrifugal compressor, axi-centrifugal compressors and mixed-flow compressors where the fluid flow will include a "radial component" through the compressor.

The Armstrong Siddeley ASX was an early axial flow jet engine built by Armstrong Siddeley that first ran in April 1943. Only a single prototype was constructed, and it was never put into production. A turboprop version as the ASP was somewhat more successful, and as the Armstrong Siddeley Python saw use in the Westland Wyvern.

A jet engine performs by converting fuel into thrust. How well it performs is an indication of what proportion of its fuel goes to waste. It transfers heat from burning fuel to air passing through the engine. In doing so it produces thrust work when propelling a vehicle but a lot of the fuel is wasted and only appears as heat. Propulsion engineers aim to minimize the degradation of fuel energy into unusable thermal energy. Increased emphasis on performance improvements for commercial airliners came in the 1970s from the rising cost of fuel.

The Bristol Orion aero engine is a two-shaft turboprop intended for use in later marks of the Bristol Britannia and the Canadair CL-44. Although the engine was built and underwent a development program, the BE.25 Orion project was cancelled in 1958 by the British Ministry of Supply in favour of the Rolls-Royce Tyne. In addition, interest in turboprop-powered aircraft was beginning to wane, because of the successful introduction of the Boeing 707 and Douglas DC-8 jetliners into airline service.

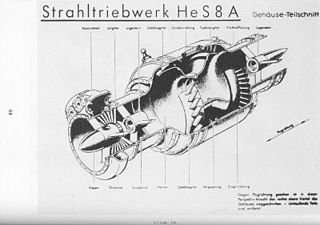

The Heinkel HeS 8 was an early jet engine designed by Hans von Ohain while working at Heinkel. It was the first jet engine to be financially supported by the RLM, bearing the official name 109-001. Had development continued it would have been known as the Heinkel 001, but it does not appear this was used in practice.

The CFE CFE738 is a small turbofan engine aimed at the business/commuter jet market manufactured by the CFE Company, and is used on the Dassault Falcon 2000.

The Rolls-Royce/Snecma Olympus 593 was an Anglo-French turbojet with reheat, which powered the supersonic airliner Concorde. It was initially a joint project between Bristol Siddeley Engines Limited (BSEL) and Snecma, derived from the Bristol Siddeley Olympus 22R engine. Rolls-Royce Limited acquired BSEL in 1966 during development of the engine, making BSEL the Bristol Engine Division of Rolls-Royce.

The General Electric T31 was the first turboprop engine designed and built in the United States.

During World War 2, the Bristol Aero Engine part of the Bristol Aeroplane Company was pre-occupied with developing and manufacturing radial piston engines, such as the Bristol Hercules and the more powerful Bristol Centaurus. However, in 1944 the Company decided to form a Project Department to investigate the design of gas turbines. Initially the department was based at Tockington Manor, a large country house close to the main factory at Patchway, Bristol. A predominantly young team was formed and was initially tasked with studying turboprop engines.

References

- 1 2 3 Baxter, Alan (1990). Olympus - the first forty years. R-RHT. pp. 13–15. ISBN 0-9511710-9-7. Historical Series, Nº15.

- ↑ Gunston, Bill (1998). Fedden – the life of Sir Roy Fedden. R-RHT. p. 239. ISBN 1-872922-13-9. Historical Series, Nº26.

- ↑ R-RHT, Olympus, p. 10.

- ↑ Buttler, Tony (2003). British Secret Projects: Jet Bombers Since 1949 . Midland Publishing. p. 16. ISBN 1-85780-130-X.

- ↑ R-RHT, Olympus, p. 13.

- ↑ Porter, Andrew (2013). Transatlantic Betrayal. Amberley Publishing. pp. 115–117. ISBN 9781445624297.

- 1 2 3 Gunston, Bill (1986). "Bristol". World Encyclopedia of Aero Engines. London: Guild Publishing. pp. 34–35. ISBN 085059717X.

- ↑ "British Power Units". Flight : 250. 4 September 1947.

- ↑ "Review of 1948". Flight : 772. 30 December 1948.

- 1 2 "Bristol Proteus (and Phoebus)". Flight : 313. 8 September 1949.

- 1 2 "Designs Of A Decade". Flight : 561. 11 May 1951.

- ↑ "Some Outstanding Achievements of 1949". Flight : 455–456. 16 February 1950.

- ↑ "Phoebus test bed". Aviation Archive.

- ↑ "Ten Thousand Test Flights". Flight : 455–456. 5 April 1957.

- ↑ R-RHT, Olympus, p. 18.

- ↑ "Costs Reviewed: The Auditor-General on the Proteus, Theseus and Phoebus". Flight : 419. 3 April 1953.