Computational fluid dynamics (CFD) is a branch of fluid mechanics that uses numerical analysis and data structures to analyze and solve problems that involve fluid flows. Computers are used to perform the calculations required to simulate the free-stream flow of the fluid, and the interaction of the fluid with surfaces defined by boundary conditions. With high-speed supercomputers, better solutions can be achieved, and are often required to solve the largest and most complex problems. Ongoing research yields software that improves the accuracy and speed of complex simulation scenarios such as transonic or turbulent flows. Initial validation of such software is typically performed using experimental apparatus such as wind tunnels. In addition, previously performed analytical or empirical analysis of a particular problem can be used for comparison. A final validation is often performed using full-scale testing, such as flight tests.

Computer-aided engineering (CAE) is the general usage of technology to aid in tasks related to engineering analysis. Any use of technology to solve or assist engineering issues falls under this umbrella.

The von Karman Institute for Fluid Dynamics (VKI) is a non-profit educational and scientific organization which specializes in three specific fields: aeronautics and aerospace, environment and applied fluid dynamics, turbomachinery and propulsion. Founded in 1956, it is located in Sint-Genesius-Rode, Belgium.

The Advection Upstream Splitting Method (AUSM) is a numerical method used to solve the advection equation in computational fluid dynamics. It is particularly useful for simulating compressible flows with shocks and discontinuities.

Tecplot is the name of a family of visualization & analysis software tools developed by American company Tecplot, Inc., which is headquartered in Bellevue, Washington. The firm was formerly operated as Amtec Engineering. In 2016, the firm was acquired by Vela Software, an operating group of Constellation Software, Inc. (TSX:CSU).

Airflow Sciences Corporation (ASC) is an engineering consulting company based in Livonia, Michigan, USA that specializes in the design and optimization of equipment and processes involving flow, heat transfer, combustion, and mass transfer. Engineering techniques include Computational Fluid Dynamics (CFD) modeling, experimental laboratory testing, and field measurements at client sites. ASC works for a wide range of industries world-wide, including power generation, manufacturing, aerospace, HVAC, food processing, biomedical, pollution control, oil and gas, rail, legal, and automotive.

OVERFLOW - the OVERset grid FLOW solver - is a software package for simulating fluid flow around solid bodies using computational fluid dynamics (CFD). It is a compressible 3-D flow solver that solves the time-dependent, Reynolds-averaged, Navier–Stokes equations using multiple overset structured grids.

The CFD-DEM model, or Computational Fluid Dynamics / Discrete Element Method model, is a process used to model or simulate systems combining fluids with solids or particles. In CFD-DEM, the motion of discrete solids or particles phase is obtained by the Discrete Element Method (DEM) which applies Newton's laws of motion to every particle, while the flow of continuum fluid is described by the local averaged Navier–Stokes equations that can be solved using the traditional Computational Fluid Dynamics (CFD) approach. The interactions between the fluid phase and solids phase is modeled by use of Newton's third law.

A CFD-DEM model is suitable for the modeling or simulation of fluid-solids or fluid-particles systems. In a typical CFD-DEM model, the phase motion of discrete solids or particles is obtained by the Discrete Element Method (DEM) which applies Newton's laws of motion to every particle and the flow of continuum fluid is described by the local averaged Navier–Stokes equations that can be solved by the traditional Computational Fluid Dynamics (CFD). The model is first proposed by Tsuji et al. The interactions between the fluid phase and solids phase is better modeled according to Newton's third law.

The moving particle semi-implicit (MPS) method is a computational method for the simulation of incompressible free surface flows. It is a macroscopic, deterministic particle method developed by Koshizuka and Oka (1996).

In applied mathematics, the name finite pointset method is a general approach for the numerical solution of problems in continuum mechanics, such as the simulation of fluid flows. In this approach the medium is represented by a finite set of points, each endowed with the relevant local properties of the medium such as density, velocity, pressure, and temperature.

The multiphase particle-in-cell method (MP-PIC) is a numerical method for modeling particle-fluid and particle-particle interactions in a computational fluid dynamics (CFD) calculation. The MP-PIC method achieves greater stability than its particle-in-cell predecessor by simultaneously treating the solid particles as computational particles and as a continuum. In the MP-PIC approach, the particle properties are mapped from the Lagrangian coordinates to an Eulerian grid through the use of interpolation functions. After evaluation of the continuum derivative terms, the particle properties are mapped back to the individual particles. This method has proven to be stable in dense particle flows, computationally efficient, and physically accurate. This has allowed the MP-PIC method to be used as particle-flow solver for the simulation of industrial-scale chemical processes involving particle-fluid flows.

KIVA is a family of Fortran-based Computational Fluid Dynamics software developed by Los Alamos National Laboratory (LANL). The software predicts complex fuel and air flows as well as ignition, combustion, and pollutant-formation processes in engines. The KIVA models have been used to understand combustion chemistry processes, such as auto-ignition of fuels, and to optimize diesel engines for high efficiency and low emissions. General Motors has used KIVA in the development of direct-injection, stratified charge gasoline engines as well as the fast burn, homogeneous-charge gasoline engine. Cummins reduced development time and cost by 10%–15% using KIVA to develop its high-efficiency 2007 ISB 6.7-L diesel engine that was able to meet 2010 emission standards in 2007. At the same time, the company realized a more robust design and improved fuel economy while meeting all environmental and customer constraints.

The extended discrete element method (XDEM) is a numerical technique that extends the dynamics of granular material or particles as described through the classical discrete element method (DEM) by additional properties such as the thermodynamic state, stress/strain or electro-magnetic field for each particle. Contrary to a continuum mechanics concept, the XDEM aims at resolving the particulate phase with its various processes attached to the particles. While the discrete element method predicts position and orientation in space and time for each particle, the extended discrete element method additionally estimates properties such as internal temperature and/or species distribution or mechanical impact with structures.

Gerris is computer software in the field of computational fluid dynamics (CFD). Gerris was released as free and open-source software, subject to the requirements of the GNU General Public License (GPL), version 2 or any later.

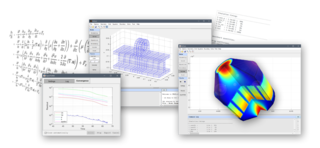

SimScale is a computer-aided engineering (CAE) software product based on cloud computing. SimScale was developed by SimScale GmbH and allows computational fluid dynamics, finite element analysis and thermal simulations. The backend of the platform uses open source codes:

FEATool Multiphysics is a physics, finite element analysis (FEA), and partial differential equation (PDE) simulation toolbox. FEATool Multiphysics features the ability to model fully coupled heat transfer, fluid dynamics, chemical engineering, structural mechanics, fluid-structure interaction (FSI), electromagnetics, as well as user-defined and custom PDE problems in 1D, 2D (axisymmetry), or 3D, all within a graphical user interface (GUI) or optionally as script files. FEATool has been employed and used in academic research, teaching, and industrial engineering simulation contexts.

Simcenter STAR-CCM+ is a commercial Computational Fluid Dynamics (CFD) based simulation software developed by Siemens Digital Industries Software. Simcenter STAR-CCM+ allows the modeling and analysis of a range of engineering problems involving fluid flow, heat transfer, stress, particulate flow, electromagnetics and related phenomena.

Lian-Ping Wang is a mechanical engineer and academic, most known for his work on computational fluid dynamics, turbulence, particle-laden flow, and immiscible multiphase flow, and their applications to industrial and atmospheric processes. He is the Chair Professor of Mechanics and Aerospace Engineering at the Southern University of Science and Technology in China, Professor of Mechanical Engineering, and Joint Professor of Physical Ocean Science and Engineering at University of Delaware.