A rivet is a permanent mechanical fastener. Before being installed, a rivet consists of a smooth cylindrical shaft with a head on one end. The end opposite the head is called the tail. On installation, the deformed end is called the shop head or buck-tail.

A fastener or fastening is a hardware device that mechanically joins or affixes two or more objects together. In general, fasteners are used to create non-permanent joints; that is, joints that can be removed or dismantled without damaging the joining components. Steel fasteners are usually made of stainless steel, carbon steel, or alloy steel.

A washer is a thin plate with a hole that is normally used to distribute the load of a threaded fastener, such as a bolt or nut. Other uses are as a spacer, spring, wear pad, preload indicating device, locking device, and to reduce vibration.

A bolted joint is one of the most common elements in construction and machine design. It consists of a male threaded fastener that captures and joins other parts, secured with a matching female screw thread. There are two main types of bolted joint designs: tension joints and shear joints.

A screw thread, often shortened to thread, is a helical structure used to convert between rotational and linear movement or force. A screw thread is a ridge wrapped around a cylinder or cone in the form of a helix, with the former being called a straight thread and the latter called a tapered thread. A screw thread is the essential feature of the screw as a simple machine and also as a threaded fastener.

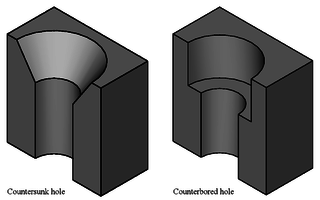

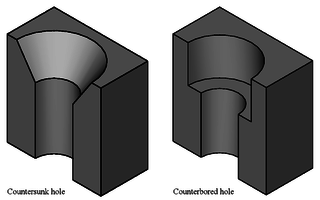

In manufacturing, a countersink is a conical hole cut into a manufactured object, or the cutter used to cut such a hole. A common use is to allow the head of a countersunk bolt, screw or rivet, when placed in the hole, to sit flush with or below the surface of the surrounding material. A countersink may also be used to remove the burr left from a drilling or tapping operation, thereby improving the finish of the product and removing any hazardous sharp edges.

A safety wire or locking-wire is a type of positive locking device that prevents fasteners from falling out due to vibration and other forces. The presence of safety wiring may also serve to indicate that the fasteners have been properly tightened.

A sex bolt is a type of mating fastener (nut) with a barrel-shaped flange and protruding boss that is internally threaded. The bolts sits within the components being fastened, and the flange provides the bearing surface. The sex bolt and accompanying machine screw sit flush on either side of the surfaces being fastened.

A fitting or adapter is used in pipe systems to connect sections of pipe or tube, adapt to different sizes or shapes, and for other purposes such as regulating fluid flow. These fittings are used in plumbing to manipulate the conveyance of fluids such as water for potatory, irrigational, sanitary, and refrigerative purposes, gas, petroleum, liquid waste, or any other liquid or gaseous substances required in domestic or commercial environments, within a system of pipes or tubes, connected by various methods, as dictated by the material of which these are made, the material being conveyed, and the particular environmental context in which they will be used, such as soldering, mortaring, caulking, Plastic welding, welding, friction fittings, threaded fittings, and compression fittings.

A threaded insert, also known as a threaded bushing, is a fastener element that is inserted into an object to add a threaded hole. They may be used to repair a stripped threaded hole, provide a durable threaded hole in a soft material, place a thread on a material too thin to accept it, mold or cast threads into a work piece thereby eliminating a machining operation, or simplify changeover from unified to metric threads or vice versa.

Multi-jackbolt tensioners (MJT) are an alternative to traditional bolted joints. Rather than needing to tighten one large bolt, MJTs use several smaller jackbolts to significantly reduce the torque required to attain a certain preload. MJTs range in thread sizes from 3⁄4 in (19 mm) to 32 in (810 mm) and can achieve 20 million pounds-force or more. MJTs only require hand-held tools, such as torque wrenches or air/electric impacts, for loading and unloading bolted joints.

A weld nut is a special type of nut specifically designed to be welded to another object. There are various types for different applications.

A barrel nut is a specialized forged nut, and is commonly used in aerospace and ready-to-assemble furniture applications.

A screw and a bolt are similar types of fastener typically made of metal and characterized by a helical ridge, called a male thread.

A nut is a type of fastener with a threaded hole. Nuts are almost always used in conjunction with a mating bolt to fasten multiple parts together. The two partners are kept together by a combination of their threads' friction, a slight stretching of the bolt, and compression of the parts to be held together.

ISO 898 is an international standard that defines mechanical and physical properties for metric fasteners. This standard is the origin for other standards that define properties for similar metric fasteners, such as SAE J1199 and ASTM F568M. It is divided into five (nonconsecutive) parts:

Strut channel, often referred to colloquially by one of several manufacturer trade names, is a standardized formed structural system used in the construction and electrical industries for light structural support, often for supporting wiring, plumbing, or mechanical components such as air conditioning or ventilation systems.

A threaded rod, also known as a stud, is a relatively long rod that is threaded on both ends; the thread may extend along the complete length of the rod. They are designed to be used in tension. Threaded rod in bar stock form is often called all-thread (ATR); other names include fully-threaded rod, redi-rod, continuously-threaded rod, and TFL rod.

A bolt is a form of threaded fastener with an external male thread requiring a matching pre-formed female thread such as a nut. Bolts are very closely related to screws.

A mechanical joint is a section of a machine which is used to connect one or more mechanical part to another. Mechanical joints may be temporary or permanent; most types are designed to be disassembled. Most mechanical joints are designed to allow relative movement of these mechanical parts of the machine in one degree of freedom, and restrict movement in one or more others.