Delft is a city and municipality in the province of South Holland, Netherlands. It is located between Rotterdam, to the southeast, and The Hague, to the northwest. Together with them, it is a part of both the Rotterdam–The Hague metropolitan area and the Randstad.

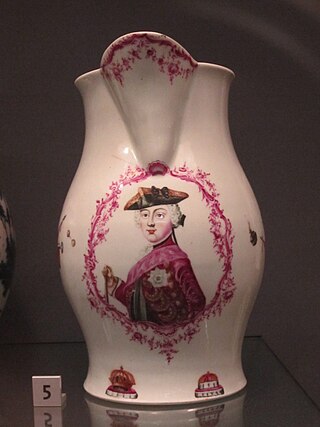

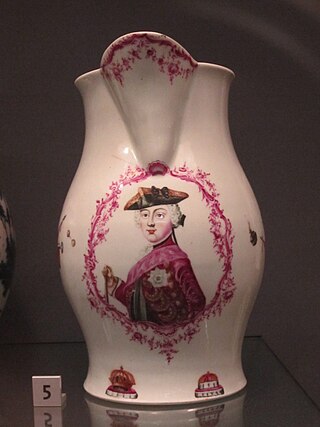

Delftware or Delft pottery, also known as Delft Blue or as delf, is a general term now used for Dutch tin-glazed earthenware, a form of faience. Most of it is blue and white pottery, and the city of Delft in the Netherlands was the major centre of production, but the term covers wares with other colours, and made elsewhere. It is also used for similar pottery, English delftware.

Porcelain is a ceramic material made by heating raw materials, generally including kaolinite, in a kiln to temperatures between 1,200 and 1,400 °C. The greater strength and translucence of porcelain, relative to other types of pottery, arise mainly from vitrification and the formation of the mineral mullite within the body at these high temperatures. End applications include tableware, decorative ware such as figurines, and products in technology and industry such as electrical insulators and laboratory ware.

Faience or faïence is the general English language term for fine tin-glazed pottery. The invention of a white pottery glaze suitable for painted decoration, by the addition of an oxide of tin to the slip of a lead glaze, was a major advance in the history of pottery. The invention seems to have been made in Iran or the Middle East before the ninth century. A kiln capable of producing temperatures exceeding 1,000 °C (1,830 °F) was required to achieve this result, the result of millennia of refined pottery-making traditions. The term is now used for a wide variety of pottery from several parts of the world, including many types of European painted wares, often produced as cheaper versions of porcelain styles.

Imari ware is a Western term for a brightly-coloured style of Arita ware Japanese export porcelain made in the area of Arita, in the former Hizen Province, northwestern Kyūshū. They were exported to Europe in large quantities, especially between the second half of the 17th century and the first half of the 18th century.

Chinese export porcelain includes a wide range of Chinese porcelain that was made (almost) exclusively for export to Europe and later to North America between the 16th and the 20th century. Whether wares made for non-Western markets are covered by the term depends on context. Chinese ceramics made mainly for export go back to the Tang dynasty if not earlier, though initially they may not be regarded as porcelain.

"Blue and white pottery" covers a wide range of white pottery and porcelain decorated under the glaze with a blue pigment, generally cobalt oxide. The decoration was commonly applied by hand, originally by brush painting, but nowadays by stencilling or by transfer-printing, though other methods of application have also been used. The cobalt pigment is one of the very few that can withstand the highest firing temperatures that are required, in particular for porcelain, which partly accounts for its long-lasting popularity. Historically, many other colours required overglaze decoration and then a second firing at a lower temperature to fix that.

The Rockingham Pottery was a 19th-century manufacturer of porcelain of international repute, supplying fine wares and ornamental pieces to royalty and the aristocracy in Britain and overseas, as well as manufacturing porcelain and earthenware items for ordinary use.

Liverpool porcelain is mostly of the soft-paste porcelain type and was produced between about 1754 and 1804 in various factories in Liverpool. Tin-glazed English delftware had been produced in Liverpool from at least 1710 at numerous potteries, but some then switched to making porcelain. A portion of the output was exported, mainly to North America and the Caribbean.

Tin-glazed pottery is earthenware covered in lead glaze with added tin oxide which is white, shiny and opaque ; usually this provides a background for brightly painted decoration. It has been important in Islamic and European pottery, but very little used in East Asia. The pottery body is usually made of red or buff-colored earthenware and the white glaze imitated Chinese porcelain. The decoration on tin-glazed pottery is usually applied to the unfired glaze surface by brush with metallic oxides, commonly cobalt oxide, copper oxide, iron oxide, manganese dioxide and antimony oxide. The makers of Italian tin-glazed pottery from the late Renaissance blended oxides to produce detailed and realistic polychrome paintings.

Royal Leerdam Crystal was a Dutch producer of glassware products based in Leerdam, the Netherlands.

Art pottery is a term for pottery with artistic aspirations, made in relatively small quantities, mostly between about 1870 and 1930. Typically, sets of the usual tableware items are excluded from the term; instead the objects produced are mostly decorative vessels such as vases, jugs, bowls and the like which are sold singly. The term originated in the later 19th century, and is usually used only for pottery produced from that period onwards. It tends to be used for ceramics produced in factory conditions, but in relatively small quantities, using skilled workers, with at the least close supervision by a designer or some sort of artistic director. Studio pottery is a step up, supposed to be produced in even smaller quantities, with the hands-on participation of an artist-potter, who often performs all or most of the production stages. But the use of both terms can be elastic. Ceramic art is often a much wider term, covering all pottery that comes within the scope of art history, but "ceramic artist" is often used for hands-on artist potters in studio pottery.

A tulip vase, or pyramid vase, is a vase designed to put cut flowers and especially tulips in, but it primarily serves as a decorative showpiece. They were first made in the Netherlands in the 17th century and were decorated with Delfts blauw or Chinese decoration. Replicas of the original tulip vases were made in China and were imported by the Dutch East India Company.

China painting, or porcelain painting, is the decoration of glazed porcelain objects such as plates, bowls, vases or statues. The body of the object may be hard-paste porcelain, developed in China in the 7th or 8th century, or soft-paste porcelain, developed in 18th-century Europe. The broader term ceramic painting includes painted decoration on lead-glazed earthenware such as creamware or tin-glazed pottery such as maiolica or faience.

Johanna Jacoba (Johnny) Rolf is a Dutch ceramist, drawing artist and sculptor.

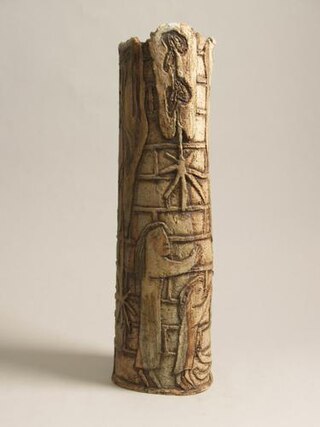

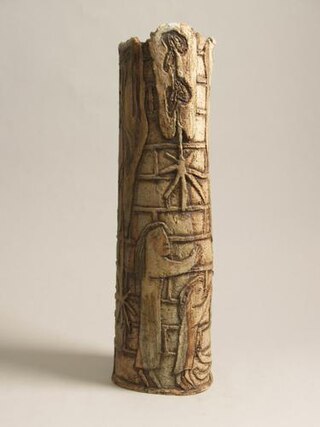

Ceramic art is art made from ceramic materials, including clay. It may take varied forms, including artistic pottery, including tableware, tiles, figurines and other sculpture. As one of the plastic arts, ceramic art is a visual art. While some ceramics are considered fine art, such as pottery or sculpture, most are considered to be decorative, industrial or applied art objects. Ceramic art can be created by one person or by a group, in a pottery or a ceramic factory with a group designing and manufacturing the artware.

Delft Jewelry is the generic name for jewelry featuring Dutch (Netherlands) miniature Delftware medallions or brooch panels in a silver setting. Delft jewelry includes necklaces, pendants, earrings, brooches, bracelets, rings, and cufflinks. The Delft panels are usually made of pottery and decorated with a blue and white windmill landscape. The silver setting often has the form of silver filigree. Delft jewelry has been made in the Netherlands since c.1879. It flourished especially in the decades after WW2 as a result of demand from the Dutch tourist industry. That era saw the emergence of three specialist producers of Delft medallions. For most other Delftware factories however, brooch panels have been a relatively small side product.

Euphemia Hendrika Maria (Phemia) Molkenboer was a Dutch ceramist, furniture designer, draughtswoman and art teacher.

Japanese export porcelain includes a wide range of porcelain that was made and decorated in Japan primarily for export to Europe and later to North America, with significant quantities going to south and southeastern Asian markets. Production for export to the West falls almost entirely into two periods, firstly between the 1650s and 1740s, and then the period from the 1850s onwards.

Willem Jansz Verstraeten was a Dutch Golden Age tin-glazed maiolica maker in Haarlem.