Related Research Articles

Polyvinyl chloride (alternatively: poly(vinyl chloride), colloquial: vinyl or polyvinyl; abbreviated: PVC) is the world's third-most widely produced synthetic polymer of plastic (after polyethylene and polypropylene). About 40 million tons of PVC are produced each year.

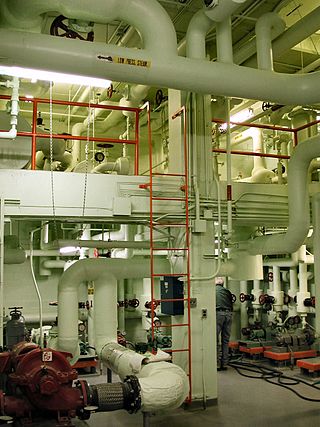

Plumbing is any system that conveys fluids for a wide range of applications. Plumbing uses pipes, valves, plumbing fixtures, tanks, and other apparatuses to convey fluids. Heating and cooling (HVAC), waste removal, and potable water delivery are among the most common uses for plumbing, but it is not limited to these applications. The word derives from the Latin for lead, plumbum, as the first effective pipes used in the Roman era were lead pipes.

A thermoplastic, or thermosoftening plastic, is any plastic polymer material that becomes pliable or moldable at a certain elevated temperature and solidifies upon cooling.

A sanitary sewer is an underground pipe or tunnel system for transporting sewage from houses and commercial buildings to a sewage treatment plant or disposal.

The Resource Conservation and Recovery Act (RCRA), enacted in 1976, is the principal federal law in the United States governing the disposal of solid waste and hazardous waste.

Within industry, piping is a system of pipes used to convey fluids from one location to another. The engineering discipline of piping design studies the efficient transport of fluid.

In modern plumbing, a drain-waste-vent is a system that allows air to enter the plumbing system to maintain proper air pressure to enable the removal of sewage and greywater from a dwelling. Drain refers to water produced at fixtures such as sinks, and showers; waste refers to water from toilets. As the water runs down, proper venting is required to allow water to flow freely, and avoid a vacuum from being created. As the water runs down air must be allowed into the waste pipe either through a roof vent (external), or an internal vent.

Industrial wastewater treatment describes the processes used for treating wastewater that is produced by industries as an undesirable by-product. After treatment, the treated industrial wastewater may be reused or released to a sanitary sewer or to a surface water in the environment. Some industrial facilities generate wastewater that can be treated in sewage treatment plants. Most industrial processes, such as petroleum refineries, chemical and petrochemical plants have their own specialized facilities to treat their wastewaters so that the pollutant concentrations in the treated wastewater comply with the regulations regarding disposal of wastewaters into sewers or into rivers, lakes or oceans. This applies to industries that generate wastewater with high concentrations of organic matter, toxic pollutants or nutrients such as ammonia. Some industries install a pre-treatment system to remove some pollutants, and then discharge the partially treated wastewater to the municipal sewer system.

An underground storage tank (UST) is, according to United States federal regulations, a storage tank, including any underground piping connected to the tank, that has at least 10 percent of its volume underground.

A gas leak refers to a leak of natural gas or another gaseous product from a pipeline or other containment into any area where the gas should not be present. Gas leaks can be hazardous to health as well as the environment. Even a small leak into a building or other confined space may gradually build up an explosive or lethal concentration of gas. Natural gas leaks and the escape of refrigerant gas into the atmosphere are especially harmful, because of their global warming potential and ozone depletion potential.

Cross-linked polyethylene, commonly abbreviated PEX, XPE or XLPE, is a form of polyethylene with cross-links. It is used predominantly in building services pipework systems, hydronic radiant heating and cooling systems, domestic water piping, insulation for high tension electrical cables, and baby play mats. It is also used for natural gas and offshore oil applications, chemical transportation, and transportation of sewage and slurries. PEX is an alternative to polyvinyl chloride (PVC), chlorinated polyvinyl chloride (CPVC) or copper tubing for use as residential water pipes.

Chlorinated polyvinyl chloride (CPVC) is a thermoplastic produced by chlorination of polyvinyl chloride (PVC) resin. CPVC is significantly more flexible than PVC, and can also withstand higher temperatures. Uses include hot and cold water delivery pipes and industrial liquid handling. CPVC, like PVC, is deemed safe for the transport and use of potable water.

A pipe is a tubular section or hollow cylinder, usually but not necessarily of circular cross-section, used mainly to convey substances which can flow — liquids and gases (fluids), slurries, powders and masses of small solids. It can also be used for structural applications; hollow pipe is far stiffer per unit weight than solid members.

There are many uses of water in industry and, in most cases, the used water also needs treatment to render it fit for re-use or disposal. Raw water entering an industrial plant often needs treatment to meet tight quality specifications to be of use in specific industrial processes. Industrial water treatment encompasses all these aspects which include industrial wastewater treatment, boiler water treatment and cooling water treatment.

A fitting or adapter is used in pipe systems to connect sections of pipe or tube, adapt to different sizes or shapes, and for other purposes such as regulating fluid flow. These fittings are used in plumbing to manipulate the conveyance of fluids such as water for potatory, irrigational, sanitary, and refrigerative purposes, gas, petroleum, liquid waste, or any other liquid or gaseous substances required in domestic or commercial environments, within a system of pipes or tubes, connected by various methods, as dictated by the material of which these are made, the material being conveyed, and the particular environmental context in which they will be used, such as soldering, mortaring, caulking, Plastic welding, welding, friction fittings, threaded fittings, and compression fittings.

A geomembrane is very low permeability synthetic membrane liner or barrier used with any geotechnical engineering related material so as to control fluid migration in a human-made project, structure, or system. Geomembranes are made from relatively thin continuous polymeric sheets, but they can also be made from the impregnation of geotextiles with asphalt, elastomer or polymer sprays, or as multilayered bitumen geocomposites. Continuous polymer sheet geomembranes are, by far, the most common.

Plastic pipe is a tubular section, or hollow cylinder, made of plastic. It is usually, but not necessarily, of circular cross-section, used mainly to convey substances which can flow—liquids and gases (fluids), slurries, powders and masses of small solids. It can also be used for structural applications; hollow pipes are far stiffer per unit weight than solid members.

Ultrapure water (UPW), high-purity water or highly purified water (HPW) is water that has been purified to uncommonly stringent specifications. Ultrapure water is a term commonly used in manufacturing to emphasize the fact that the water is treated to the highest levels of purity for all contaminant types, including: organic and inorganic compounds; dissolved and particulate matter; volatile and non-volatile; reactive, and inert; hydrophilic and hydrophobic; and dissolved gases.

A gas cabinet is a metallic enclosure which is used to provide local exhaust ventilation system for virtually all of the gases used or generated in the semiconductor, solar, MEMS, NANO, solar PV, manufacturing and other advanced technologies.

In the process industry, chemical industry, manufacturing industry, and other commercial and industrial contexts, pipe marking is used to identify the contents, properties and flow direction of fluids in piping. It is typically carried out by marking piping through labels and color codes. Pipe marking helps personnel and fire response teams identify the correct pipes for operational, maintenance or emergency response purposes.

References

- ↑ Basta, Nick Double up to contain leaks Chemical Processing, Putman Media, Inc.; 20 December 2004; accessed Jan 2010

- ↑ 40 CFR § 280.41

- ↑ Woodside, Gayle – Hazardous materials and hazardous waste management – page 222, Second Edition 1999, John Wiley and Sons; 477 pages

- ↑ Center for Continuous Process Safety, New York, NY Continuous monitoring for hazardous material releases , John Wiley & Sons, added to ScibD 28 October 2009; 104 pages

- ↑ Hairston, James E. Underground Storage Tanks (USTs) And NPS Pollution Alabama Cooperative Extension System; ANR-790-4.8.3, June 1995; accessed 2010

- ↑ Frankel, Michael – Facility Piping Systems Handbook: For Industrial, Commercial, and Healthcare, Chapter 2.46, Third Edition, McGraw Hill, Copyright 2010

- ↑ "Rocketplumbingnow". Wednesday, 9 June 2021