The pipe organ is a musical instrument that produces sound by driving pressurised air through the organ pipes selected from a keyboard. Because each pipe produces a single pitch, the pipes are provided in sets called ranks, each of which has a common timbre, volume, and construction throughout the keyboard compass. Most organs have many ranks of pipes of differing pitch, timbre, and volume that the player can employ singly or in combination through the use of controls called stops.

A railway air brake is a railway brake power braking system with compressed air as the operating medium. Modern trains rely upon a fail-safe air brake system that is based upon a design patented by George Westinghouse on April 13, 1869. The Westinghouse Air Brake Company was subsequently organized to manufacture and sell Westinghouse's invention. In various forms, it has been nearly universally adopted.

Pneumatics is a branch of engineering that makes use of gas or pressurized air.

Æolian-Skinner Organ Company, Inc. of Boston, Massachusetts was an American builder of a large number of pipe organs from its inception as the Skinner Organ Company in 1901 until its closure in 1972. Key figures were Ernest M. Skinner (1866–1960), Arthur Hudson Marks (1875–1939), Joseph Silver Whiteford (1921-1978), and G. Donald Harrison (1889–1956). The company was formed from the merger of the Skinner Organ Company and the pipe organ division of the Æolian Company in 1932.

A pedalboard is a keyboard played with the feet that is usually used to produce the low-pitched bass line of a piece of music. A pedalboard has long, narrow lever-style keys laid out in the same semitone scalar pattern as a manual keyboard, with longer keys for C, D, E, F, G, A, and B, and shorter, raised keys for C♯, D♯, F♯, G♯ and A♯. Training in pedal technique is part of standard organ pedagogy in church music and art music.

A theatre organ is a type of pipe organ developed to accompany silent films from the 1900s to the 1920s.

A tremulant is a device on a pipe organ which varies the wind supply to the pipes of one or more divisions. This causes their amplitude and pitch to fluctuate, producing a tremolo and vibrato effect. A large organ may have several tremulants, affecting different ranks (sets) of pipes. Many tremulants are variable, allowing for the speed and depth of tremolo to be controlled by the organist. The tremulant has been a part of organ building for many centuries, dating back to Italian organs of the sixteenth century.

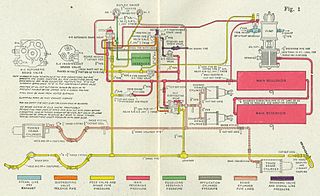

Tracker action is a term used in reference to pipe organs and steam calliopes to indicate a mechanical linkage between keys or pedals pressed by the organist and the valve that allows air to flow into pipe(s) of the corresponding note. This is in contrast to "direct electric action" and "electro-pneumatic action", which connect the key to the valve through an electrical link or an electrically assisted pneumatic system respectively, or "tubular-pneumatic action" which utilizes a change of pressure within lead tubing which connects the key to the valve pneumatic.

Robert Hope-Jones was an English musician who is considered to be the inventor of the theatre organ in the early 20th century. He thought that a pipe organ should be able to imitate the instruments of an orchestra, and that the console should be detachable from the organ.

The electro-pneumatic brake system on British mainline railway trains was introduced in 1950 and remains the primary braking system for multiple units in service today, although London Transport underground trains had been fitted with EP brakes since the 1920s. The Southern Region of British Railways operated a self-contained fleet of electric multiple units for suburban and middle-distance passenger trains. From 1950, an expansion of the fleet was undertaken and the new build adopted a braking system that was novel in the UK, the electro-pneumatic brake in which compressed air brake operation was controlled electrically by the driver. This was a considerable and successful technical advance, enabling a quicker and more sensitive response to the driver's operation of brake controls.

Electronically controlled pneumatic brakes are a type of railway braking systems.

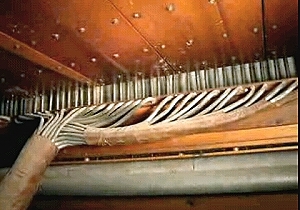

"Tubular-pneumatic action" refers to an apparatus used in many pipe organs built during the late 19th and early 20th centuries. The term "tubular" refers to the extensive use of lead tubing to connect the organ's console to the valves that control the delivery of "wind" to the organ's pipes. Many such organs are extant 100 or more years after their construction.

Direct electric action is a systems used in pipe organs to control the flow of air (wind) into the organ's pipes when the corresponding keys or pedals are depressed. In direct electric action, the valves beneath the pipes are opened directly by electro-magnet solenoids, while with electro-pneumatic action, the electro-magnet's action admits air into a pneumatic or small bellows which in turn operates the pipe's valve.

The Schoenstein Organ at the Conference Center is a pipe organ built by Schoenstein & Co., San Francisco, California located in the Conference Center of the Church of Jesus Christ of Latter-day Saints in Salt Lake City, Utah. The organ was completed in 2003. It is composed of 160 speaking stops spread over five manuals and pedals. Along with the nearby Salt Lake Tabernacle organ, it is typically used to accompany the Tabernacle Choir at Temple Square. Schoenstein & Co.'s president and tonal director, Jack Bethards, describes it as "an American Romantic organ" that is "probably more English than anything else."

The Logan Tabernacle is a tabernacle of the Church of Jesus Christ of Latter-day Saints and is located in Logan, Cache County, Utah. It is used regularly for church meetings, most often semi-annual stake conferences, seminary graduations, musical concerts, and lectures. The tabernacle welcomes visitors and is open for tours each summer from June to September. It is the site of many local celebrations, including the city's annual Summerfest Arts Faire held each June on the tabernacle grounds.

The Brindley organ of St Mary's Church, Tickhill, South Yorkshire, England is a Victorian pipe organ influenced by the German organ building tradition.

Casavant Frères Ltée. Opus 1841 is a pipe organ built by the famous Casavant Frères of Saint-Hyacinthe, Quebec. The organ was first completed in 1911 as Casavant Brothers - Opus 452 for St. Andrew's Presbyterian Church at 40 Bentinck Street, Sydney, Nova Scotia, Canada. St. Andrew's later became St. Andrew's United Church and is now the Highland Arts Theatre.

The organ of St. Ludgeri in Norden was built from 1686 to 1692 by Arp Schnitger. It has 46 stops, five divisions, three manuals and pedal, and is thus the second-largest surviving Schnitger organ in Germany and until 2018 the largest organ in East Frisia. Historically and musically it is considered an art-work of international rank.

In engineering, a solenoid is a device that converts electrical energy to mechanical energy, using an electromagnet formed from a coil of wire. The device creates a magnetic field from electric current, and uses the magnetic field to create linear motion.