A turboprop is a turbine engine that drives an aircraft propeller.

A model aircraft is a physical model of an existing or imagined aircraft, and is built typically for display, research, or amusement. Model aircraft are divided into two basic groups: flying and non-flying. Non-flying models are also termed static, display, or shelf models.

The National Advisory Committee for Aeronautics (NACA) was a United States federal agency that was founded on March 3, 1915, to undertake, promote, and institutionalize aeronautical research. On October 1, 1958, the agency was dissolved and its assets and personnel were transferred to the newly created National Aeronautics and Space Administration (NASA). NACA is an initialism, i.e., pronounced as individual letters, rather than as a whole word.

The Robert J. Collier Trophy is an annual aviation award administered by the U.S. National Aeronautic Association (NAA), presented to those who have made "the greatest achievement in aeronautics or astronautics in America, with respect to improving the performance, efficiency, and safety of air or space vehicles, the value of which has been thoroughly demonstrated by actual use during the preceding year."

A conventional fixed-wing aircraft flight control system (AFCS) consists of flight control surfaces, the respective cockpit controls, connecting linkages, and the necessary operating mechanisms to control an aircraft's direction in flight. Aircraft engine controls are also considered flight controls as they change speed.

In marine propulsion, a variable-pitch propeller is a type of propeller with blades that can be rotated around their long axis to change the blade pitch. Reversible propellers—those where the pitch can be set to negative values—can also create reverse thrust for braking or going backwards without the need to change the direction of shaft revolution.

An airplane or aeroplane, informally plane, is a fixed-wing aircraft that is propelled forward by thrust from a jet engine, propeller, or rocket engine. Airplanes come in a variety of sizes, shapes, and wing configurations. The broad spectrum of uses for airplanes includes recreation, transportation of goods and people, military, and research. Worldwide, commercial aviation transports more than four billion passengers annually on airliners and transports more than 200 billion tonne-kilometers of cargo annually, which is less than 1% of the world's cargo movement. Most airplanes are flown by a pilot on board the aircraft, but some are designed to be remotely or computer-controlled such as drones.

Hamilton Standard was an American aircraft propeller parts supplier. It was formed in 1929 when United Aircraft and Transport Corporation consolidated Hamilton Aero Manufacturing and Standard Steel Propeller into the Hamilton Standard Propeller Corporation. Other members of United Aircraft included Boeing, United Airlines, Sikorsky and Pratt & Whitney. At the time, Hamilton was the largest manufacturer of aircraft propellers in the world.

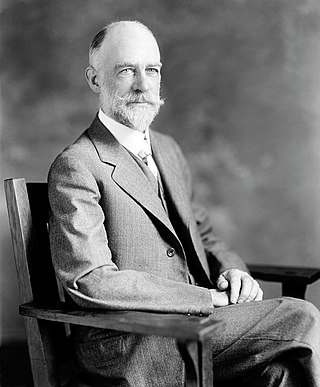

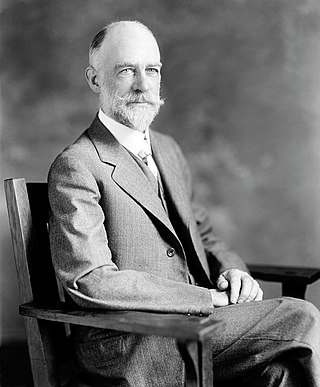

William Frederick Durand was a United States naval officer and pioneer mechanical engineer. He contributed significantly to the development of aircraft propellers. He was the first civilian chair of the National Advisory Committee for Aeronautics, the forerunner of NASA.

The CAC CA-15, was an Australian propeller-driven fighter aircraft designed by the Commonwealth Aircraft Corporation (CAC) during World War II. Due to protracted development, the project was not completed until after the war, and was cancelled after flight testing, when the advent of jet aircraft was imminent.

Blade pitch or simply pitch refers to the angle of a blade in a fluid. The term has applications in aeronautics, shipping, and other fields.

Fred Ernest Weick (1899–1993) was an airmail pilot, research engineer, and aircraft designer. Working at the NACA, he won the 1929 Collier Trophy for his design of the NACA cowling for radial air-cooled engines. Weick's aircraft designs include the Ercoupe, Piper PA-25 Pawnee, and Cherokee.

In aeronautics, a variable-pitch propeller is a type of propeller (airscrew) with blades that can be rotated around their long axis to change the blade pitch. A controllable-pitch propeller is one where the pitch is controlled manually by the pilot. Alternatively, a constant-speed propeller is one where the pilot sets the desired engine speed (RPM), and the blade pitch is controlled automatically without the pilot's intervention so that the rotational speed remains constant. The device which controls the propeller pitch and thus speed is called a propeller governor or constant speed unit.

In aeronautics, an aircraft propeller, also called an airscrew, converts rotary motion from an engine or other power source into a swirling slipstream which pushes the propeller forwards or backwards. It comprises a rotating power-driven hub, to which are attached several radial airfoil-section blades such that the whole assembly rotates about a longitudinal axis. The blade pitch may be fixed, manually variable to a few set positions, or of the automatically variable "constant-speed" type.

The Tecnam P2002 Sierra is a two-seat, low-wing, light aircraft designed and constructed by the Italian aircraft manufacturer Tecnam. Introduced during the early 2000s, the aircraft quickly became a staple of the company's product lineup, comprising 70 per cent of its available production capacity during some years.

The Prescott Pusher is an American, four-seat, pusher configuration homebuilt aircraft, with a large cockpit, retractable or fixed gear, and a T-tail. The pilot and passengers enter the aircraft through a large left-side clamshell door.

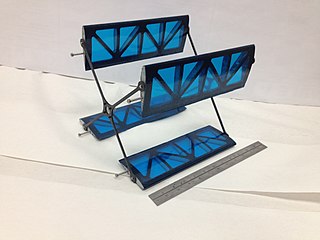

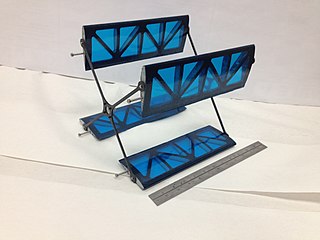

A cyclorotor, cycloidal rotor, cycloidal propeller or cyclogiro, is a fluid propulsion device that converts shaft power into the acceleration of a fluid using a rotating axis perpendicular to the direction of fluid motion. It uses several blades with a spanwise axis parallel to the axis of rotation and perpendicular to the direction of fluid motion. These blades are cyclically pitched twice per revolution to produce force in any direction normal to the axis of rotation. Cyclorotors are used for propulsion, lift, and control on air and water vehicles. An aircraft using cyclorotors as the primary source of lift, propulsion, and control is known as a cyclogyro or cyclocopter. A unique aspect is that it can change the magnitude and direction of thrust without the need of tilting any aircraft structures. The patented application, used on ships with particular actuation mechanisms both mechanical or hydraulic, is named after German company Voith Turbo.

The Propeller Research Tunnel (PRT) was the first full-scale wind tunnel at the National Advisory Committee for Aeronautics (NACA) Langley Research Center, and the third at the facility. It was in use between 1927 and 1950 and was instrumental in the drag reduction research of early American aeronautics. In 1929, NACA was awarded its first Collier Trophy for the NACA cowling which was tested and developed using the Propeller Research Tunnel.

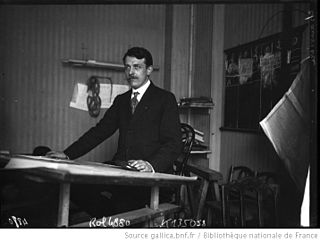

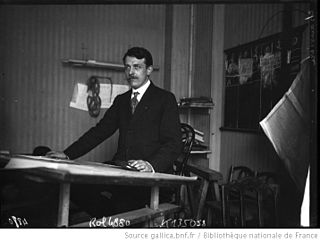

Lucien Chauvière (1876–1966) was a French aeronautical engineer. He is best known for his Integrale propellers, which were the first aerodynamically advanced propellers manufactured in Europe.

Ernest Gilbert McCauley was an American aviation pioneer who in 1938 founded McCauley Aviation Corporation. He began his career at the government's Propeller Research Department of the Airplane Design Section, Aviation Section of the Signal Corps based at McCook Field, Dayton, Ohio. In 1939, McCauley reincorporated McCauley Aviation Corporation into McCauley Steel Propeller Company. In December 1941 McCauley's company increased production from 700 to 1500 propellers per month, supporting the war effort.