MEMS is the technology of microscopic devices incorporating both electronic and moving parts. MEMS are made up of components between 1 and 100 micrometres in size, and MEMS devices generally range in size from 20 micrometres to a millimetre, although components arranged in arrays can be more than 1000 mm2. They usually consist of a central unit that processes data and several components that interact with the surroundings.

Etching is traditionally the process of using strong acid or mordant to cut into the unprotected parts of a metal surface to create a design in intaglio (incised) in the metal. In modern manufacturing, other chemicals may be used on other types of material. As a method of printmaking, it is, along with engraving, the most important technique for old master prints, and remains in wide use today. In a number of modern variants such as microfabrication etching and photochemical milling, it is a crucial technique in modern technology, including circuit boards.

Printmaking is the process of creating artworks by printing, normally on paper, but also on fabric, wood, metal, and other surfaces. "Traditional printmaking" normally covers only the process of creating prints using a hand processed technique, rather than a photographic reproduction of a visual artwork which would be printed using an electronic machine ; however, there is some cross-over between traditional and digital printmaking, including risograph.

Hydrofluoric acid is a solution of hydrogen fluoride (HF) in water. Solutions of HF are colorless, acidic and highly corrosive. A common concentration is 49% (48-52%) but there are also stronger solutions and pure HF has a boiling point near room temperature. It is used to make most fluorine-containing compounds; examples include the commonly used pharmaceutical antidepressant medication fluoxetine (Prozac) and the material PTFE (Teflon). Elemental fluorine is produced from it. It is commonly used to etch glass and silicon wafers.

Gilding is a decorative technique for applying a very thin coating of gold over solid surfaces such as metal, wood, porcelain, or stone. A gilded object is also described as "gilt". Where metal is gilded, the metal below was traditionally silver in the West, to make silver-gilt objects, but gilt-bronze is commonly used in China, and also called ormolu if it is Western. Methods of gilding include hand application and gluing, typically of gold leaf, chemical gilding, and electroplating, the last also called gold plating. Parcel-gilt objects are only gilded over part of their surfaces. This may mean that all of the inside, and none of the outside, of a chalice or similar vessel is gilded, or that patterns or images are made up by using a combination of gilt and ungilted areas.

Photogravure is a process for printing photographs, also sometimes used for reproductive intaglio printmaking. It is a photo-mechanical process whereby a copper plate is grained and then coated with a light-sensitive gelatin tissue which had been exposed to a film positive, and then etched, resulting in a high quality intaglio plate that can reproduce detailed continuous tones of a photograph.

Dental sealants are a dental treatment intended to prevent tooth decay. Teeth have recesses on their biting surfaces; the back teeth have fissures (grooves) and some front teeth have cingulum pits. It is these pits and fissures that are most vulnerable to tooth decay because food and bacteria stick in them and because they are hard-to-clean areas. Dental sealants are materials placed in these pits and fissures to fill them in, creating a smooth surface which is easy to clean. Dental sealants are mainly used in children who are at higher risk of tooth decay, and are usually placed as soon as the adult molar teeth come through.

Intaglio is the family of printing and printmaking techniques in which the image is incised into a surface and the incised line or sunken area holds the ink. It is the direct opposite of a relief print where the parts of the matrix that make the image stand above the main surface.

Porous silicon is a form of the chemical element silicon that has introduced nanopores in its microstructure, rendering a large surface to volume ratio in the order of 500 m2/cm3.

Piranha solution, also known as piranha etch, is a mixture of sulfuric acid and hydrogen peroxide. The resulting mixture is used to clean organic residues off substrates, for example silicon wafers. Because the mixture is a strong oxidizing agent, it will decompose most organic matter, and it will also hydroxylate most surfaces, making them highly hydrophilic (water-compatible). This means the solution can also easily dissolve fabric and skin, potentially causing severe damage and chemical burns in case of inadvertent contact. It is named after the piranha fish due to its tendency to rapidly dissolve and 'consume' organic materials through vigorous chemical reactions.

Etching is used in microfabrication to chemically remove layers from the surface of a wafer during manufacturing. Etching is a critically important process module in fabrication, and every wafer undergoes many etching steps before it is complete.

Glass etching, or "French embossing", is a popular technique developed during the mid-1800s that is still widely used in both residential and commercial spaces today. Glass etching comprises the techniques of creating art on the surface of glass by applying acidic, caustic, or abrasive substances. Traditionally this is done after the glass is blown or cast, although mold-etching has replaced some forms of surface etching. The removal of minute amounts of glass causes the characteristic rough surface and translucent quality of frosted glass.

Buffered oxide etch (BOE), also known as buffered HF or BHF, is a wet etchant used in microfabrication. It is a mixture of a buffering agent, such as ammonium fluoride NH4F, and hydrofluoric acid (HF). Its primary use is in etching thin films of silicon nitride (Si3N4) or silicon dioxide (SiO2), by the reaction:

Stain removal is the process of removing a mark or spot left by one substance on a specific surface like a fabric. A solvent or detergent is generally used to conduct stain removal and many of these are available over the counter.

Chemical milling or industrial etching is the subtractive manufacturing process of using baths of temperature-regulated etching chemicals to remove material to create an object with the desired shape. Other names for chemical etching include photo etching, chemical etching, photo chemical etching and photochemical machining. It is mostly used on metals, though other materials are increasingly important. It was developed from armor-decorating and printing etching processes developed during the Renaissance as alternatives to engraving on metal. The process essentially involves bathing the cutting areas in a corrosive chemical known as an etchant, which reacts with the material in the area to be cut and causes the solid material to be dissolved; inert substances known as maskants are used to protect specific areas of the material as resists.

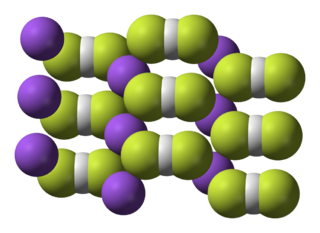

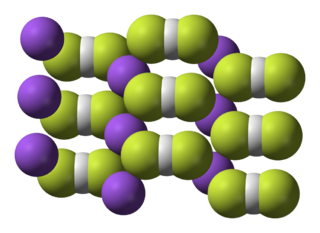

Sodium bifluoride is the inorganic compound with the formula Na[HF2]. It is a salt of sodium cation and bifluoride anion. It is a white, water-soluble solid that decomposes upon heating. Sodium bifluoride is non-flammable, hygroscopic, and has a pungent smell. Sodium bifluoride has a number of applications in industry.

A hydrofluoric acid burn is a chemical burn from hydrofluoric acid. Where it contacts the skin it results in significant pain, swelling, redness, and skin breakdown. If the fumes are breathed in swelling of the upper airway and bleeding may occur. Complications can include electrolyte, heart, lung, kidney, and neurological problems.

Fossil preparation is a complex of tasks that can include excavating, revealing, conserving, and replicating the ancient remains and traces of organisms. It is an integral part of the science of paleontology, of museum exhibition, and the preservation of fossils held in the public trust. It involves a wide variety of techniques, from the mechanical to the chemical, depending upon the qualities of the specimen being prepared and the goals of the effort. Fossil preparation may be executed by scientists, students or collections personnel, but is often undertaken by professional fossil preparators.

Glass printing involves applying images, patterns, or text to glass surfaces. Various techniques can be used, each offering distinct aesthetic and functional results. This specialized field encompasses methods such as screen printing, digital printing, and pad printing, among others. Each technique offers distinct advantages in terms of durability, resolution, and application. Glass printing is used in numerous industries, including architecture, automotive, interior design, and consumer electronics, where it is valued for its aesthetic appeal, functionality, and ability to enhance the visual and physical properties of glass products. Technological advances have expanded the possibilities of glass printing, allowing for intricate designs, vibrant colors, and improved adhesion, making it an integral part of modern manufacturing and design.