Günter Petzow (8 July 1926 – 4 February 2024) was a German materials scientist and the director at the Max Planck Institute for Metals Research. [1]

Günter Petzow (8 July 1926 – 4 February 2024) was a German materials scientist and the director at the Max Planck Institute for Metals Research. [1]

Günter Petzow was born in Nordhausen, Thuringia on 8 July 1926. He studied Chemistry and Physical Metallurgy at the University of Stuttgart and the Max Planck Institute for Metals Research. He received his master's degree (Dipl.-Ing) in 1956 and finished his dissertation (Dr. rer. nat.) on Phase Equilibria of Quarternary Metallic Systems in 1959. Afterwards, he took over as the head of two research groups: phase diagrams of metallic systems and metallography in Stuttgart. Furthermore, he built up the Powder Metallurgical Laboratory in Stuttgart-Büsnau as a place of interdisciplinary research, which attracted guest researchers from all over the world. As a result, the current large campus of the MPG has been established. In 1973 he was appointed scientific member of the board of directors of the Max Planck Society. He was executive managing director of Max-Planck-Institute for Metals Research in Stuttgart and also professor at the Universities of Stuttgart and Berlin, where he taught courses in equilibrium phase diagrams and powder metallurgy. His main scientific interests dealt with problems in the field of physical metallurgy, powder metallurgy, special ceramics and phase diagrams of metallic and ceramic materials. He was the author and co-author of more than 600 research papers, 10 books, and held 27 patents.

Some of his most important papers and publications are on phase equilibria between intermetallic compounds to the knowledge of peritectic reactions, constitution and properties of cermets, metallography, high-temperature materials, Beryllium and its compounds, liquid phase sintering, particle rearrangement, metallographic etching, toughening of ceramics, Sialon ceramics, sintering of Si3N4 ceramics, metal-ceramic interfaces and processing of advanced ceramics. One important achievement was, by using sophisticated reinforcing mechanisms of the originally brittle ceramic, to create a reliable "quasi-ductility" and thus operational capability for excessive mechanical and thermal loads. Prof. Petzow was president of the German Society for Materials and acts on the board of directors of several scientific societies. He was chairman of the European Action COST 507 "Measurement and Evaluation of Thermochemical and Thermophysical Properties to Provide a Database for the Development of New Light Alloys". He was the founding editor of the journal "Practical Metallography", was editor-in-chief of "Zeitschrift für Metallkunde", editor of the book series "Ternary Alloys" [2] and member of several scientific academies and advisory boards. [3] In 1989, he was awarded the Skaupy Prize by the Community Committee Powder Metallurgy for outstanding achievements in the field of powder metallurgy. [4] Petzow received seven honorary doctorates, six honorary professorships and seven honorary memberships in prestigious scientific societies. Since 1993 he has been a full member of the Academia Europaea. The "Günter Petzow Prize" for outstanding research is awarded to a young scientist each year at an annual summer colloquium in Stuttgart. [5]

Petzow died on 4 February 2024, at the age of 97. [6]

Source: [3]

Source: [3]

Sintering or frittage is the process of compacting and forming a solid mass of material by pressure or heat without melting it to the point of liquefaction. Sintering happens as part of a manufacturing process used with metals, ceramics, plastics, and other materials. The nanoparticles in the sintered material diffuse across the boundaries of the particles, fusing the particles together and creating a solid piece.

Tantalum carbides (TaC) form a family of binary chemical compounds of tantalum and carbon with the empirical formula TaCx, where x usually varies between 0.4 and 1. They are extremely hard, brittle, refractory ceramic materials with metallic electrical conductivity. They appear as brown-gray powders, which are usually processed by sintering.

John Werner Cahn was an American scientist and recipient of the 1998 National Medal of Science. Born in Cologne, Weimar Germany, he was a professor in the department of metallurgy at the Massachusetts Institute of Technology (MIT) from 1964 to 1978. From 1977, he held a position at the National Institute of Standards and Technology. Cahn had a profound influence on the course of materials research during his career. One of the foremost authorities on thermodynamics, Cahn applied the basic laws of thermodynamics to describe and predict a wide range of physical phenomena.

Ceramic engineering is the science and technology of creating objects from inorganic, non-metallic materials. This is done either by the action of heat, or at lower temperatures using precipitation reactions from high-purity chemical solutions. The term includes the purification of raw materials, the study and production of the chemical compounds concerned, their formation into components and the study of their structure, composition and properties.

Professor Drago Kolar (1932–2000) was a head of the Ceramics Department at the Jozef Stefan Institute from 1965 until 1997.

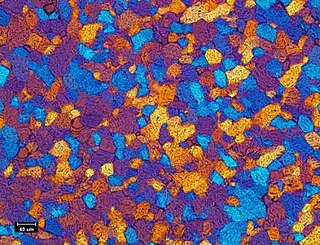

Ceramography is the art and science of preparation, examination and evaluation of ceramic microstructures. Ceramography can be thought of as the metallography of ceramics. The microstructure is the structure level of approximately 0.1 to 100 μm, between the minimum wavelength of visible light and the resolution limit of the naked eye. The microstructure includes most grains, secondary phases, grain boundaries, pores, micro-cracks and hardness microindentations. Most bulk mechanical, optical, thermal, electrical and magnetic properties are significantly affected by the microstructure. The fabrication method and process conditions are generally indicated by the microstructure. The root cause of many ceramic failures is evident in the microstructure. Ceramography is part of the broader field of materialography, which includes all the microscopic techniques of material analysis, such as metallography, petrography and plastography. Ceramography is usually reserved for high-performance ceramics for industrial applications, such as 85–99.9% alumina (Al2O3) in Fig. 1, zirconia (ZrO2), silicon carbide (SiC), silicon nitride (Si3N4), and ceramic-matrix composites. It is seldom used on whiteware ceramics such as sanitaryware, wall tiles and dishware.

Tanjore Ramachandra Anantharaman was one of India's pre-eminent metallurgists and materials scientists.

Hot pressing is a high-pressure, low-strain-rate powder metallurgy process for forming of a powder or powder compact at a temperature high enough to induce sintering and creep processes. This is achieved by the simultaneous application of heat and pressure.

Joachim Maier is Emeritus Director at the Max Planck Institute for Solid State Research in Stuttgart (Germany) and Scientific Member of the Max Planck Society.

Compaction of ceramic powders is a forming technique for ceramics in which granular ceramic materials are made cohesive through mechanical densification, either by hot or cold pressing. The resulting green part must later be sintered in a kiln. The compaction process permits an efficient production of parts to close tolerances with low drying shrinkage. It can be used for parts ranging widely in size and shape, and for both technical and nontechnical ceramics.

William David Kingery was an American material scientist who developed systematic methods for the study of ceramics. For his work, he was awarded the Kyoto Prize in 1999.

Fritz Aldinger is a German materials scientist.

Govindan Sundararajan is an Indian materials engineer, known for his contributions in the areas of Surface Engineering and Ballistics. The Government of India honoured him, in 2014, by awarding him the Padma Shri, the fourth highest civilian award, for his contributions to the fields of science and technology.

Yury Georgievich Gogotsi is a Ukrainian scientist in the field of material chemistry, professor at Drexel University, Philadelphia, United States since 2000 in the fields of Materials Science and Engineering and Nanotechnology. Distinguished University and Trustee Chair professor of materials science at Drexel University — director of the A.J. Drexel Nanotechnology Institute.

Frank Mücklich is a German materials scientist. He is professor at Saarland University and leads the Chair of Functional Materials.

Michel Barsoum is an American material scientist and engineer, currently a distinguished professor at Drexel University, Philadelphia, Pennsylvania, in the field of materials science and engineering and also a published author. In 2009, he became the holder of the A. W. Grosvenor Professorship at Drexel.

David S. Wilkinson is a Canadian material scientist and engineer, Distinguished University Professor at McMaster University. He was formerly Dean if Engineering (2008-2012) and then Provost and Vice-President of the university (2012-2017). In 1985–1986 Alexander von Humboldt Foundation Fellowship for research in Germany, held at the Max Planck Institute for Metals Research, Stuttgart. 1996, Elected Chair, Gordon Research Conference on Solid State Studies in Ceramics. 1996, Best Materials Paper, Canadian Metallurgical Quarterly 1999, Fellowship of the Canadian Institute of Mining, Metallurgy and Petroleum 2000 2000 Fellowship of the American Ceramic Society.

Carol Anne Handwerker is an American materials scientist. She is the Reinhardt Schuhmann, Jr. Professor of Materials Engineering and Environmental and Ecological Engineering at Purdue University. She is a fellow of both The Minerals, Metals & Materials Society and the Materials Research Society.

Hellmut Friedrich Fischmeister was an Austrian metallurgist who was a pioneer in powder metallurgy.

Olivier Guillon is a French-German materials scientist and engineer. He is the Director of the Institute of Energy and Climate Research (IEK-1): Materials Synthesis and Processing at Forschungszentrum Jülich and professor at RWTH Aachen University.