Related Research Articles

A brake is a mechanical device that inhibits motion by absorbing energy from a moving system. It is used for slowing or stopping a moving vehicle, wheel, axle, or to prevent its motion, most often accomplished by means of friction.

A hybrid vehicle is one that uses two or more distinct types of power, such as submarines that use diesel when surfaced and batteries when submerged. Other means to store energy include pressurized fluid in hydraulic hybrids.

Regenerative braking is an energy recovery mechanism that slows down a moving vehicle or object by converting its kinetic energy or potential energy into a form that can be either used immediately or stored until needed.

A vehicle start-stop system or stop-start system automatically shuts down and restarts the internal combustion engine to reduce the amount of time the engine spends idling, thereby reducing fuel consumption and emissions. This is most advantageous for vehicles which spend significant amounts of time waiting at traffic lights or frequently come to a stop in traffic jams. Start-stop technology may become more common with more stringent government fuel economy and emissions regulations. This feature is present in hybrid electric vehicles, but has also appeared in vehicles which lack a hybrid electric powertrain. For non-electric vehicles fuel economy gains from this technology are typically in the range of 3–10%, potentially as high as 12%. In the United States, idling wastes approximately 14.8 billion liters of gasoline per year.

The Honda Insight is a hybrid electric vehicle that is manufactured and marketed by Honda. Its first generation was a two-door, two passenger liftback (1999–2006) and in its second generation was a four-door, five passenger liftback (2009–2014). In its third generation, it became a four-door sedan (2018–2022). It was Honda's first model with Integrated Motor Assist system and the most fuel efficient gasoline-powered car available in the U.S. without plug-in capability — for the length of its production run.

The Ford Escape is a compact crossover SUV sold by Ford since the 2001 model year. The first Ford SUV derived from a car platform, the Escape was slotted below the Ford Explorer in size; the Escape is currently sized between the Ford EcoSport and Ford Edge. In another first, the 2004 Ford Escape Hybrid was the first hybrid-electric vehicle from Ford, and the first hybrid produced as an SUV.

A dynamometer or "dyno" for short, is a device for simultaneously measuring the torque and rotational speed (RPM) of an engine, motor or other rotating prime mover so that its instantaneous power may be calculated, and usually displayed by the dynamometer itself as kW or bhp.

Engine braking occurs when the retarding forces within an internal combustion engine are used to slow down a motor vehicle, as opposed to using additional external braking mechanisms such as friction brakes or magnetic brakes.

Hybrid Synergy Drive (HSD), also known as Toyota Hybrid System II, is the brand name of Toyota Motor Corporation for the hybrid car drive train technology used in vehicles with the Toyota and Lexus marques. First introduced on the Prius, the technology is an option on several other Toyota and Lexus vehicles and has been adapted for the electric drive system of the hydrogen-powered Mirai, and for a plug-in hybrid version of the Prius. Previously, Toyota also licensed its HSD technology to Nissan for use in its Nissan Altima Hybrid. Its parts supplier Aisin Seiki Co. offers similar hybrid transmissions to other car companies.

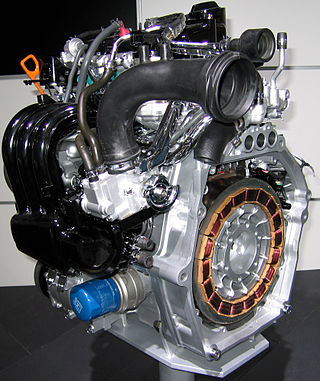

Integrated Motor Assist is Honda's hybrid car technology, introduced in 1999 on the Insight. It is a specific implementation of a parallel hybrid. It uses an electric motor mounted between the internal combustion engine and transmission to act as a starter motor, engine balancer, and assist traction motor.

BAS is a category of automotive parallel hybrid technology that uses an electric motor to contribute power to the internal combustion engine's crankshaft via a serpentine belt. By mounting this motor generator unit in the conventional location traditionally used for the standard automotive alternator, it permits a low-cost method of adding mild hybrid capabilities such as start-stop, power assist, and mild levels of regenerative braking. BAS systems differ from other mild hybrid systems as they are not run off the vehicle's crankshaft.

The fuel economy of an automobile relates to the distance traveled by a vehicle and the amount of fuel consumed. Consumption can be expressed in terms of the volume of fuel to travel a distance, or the distance traveled per unit volume of fuel consumed. Since fuel consumption of vehicles is a significant factor in air pollution, and since the importation of motor fuel can be a large part of a nation's foreign trade, many countries impose requirements for fuel economy. Different methods are used to approximate the actual performance of the vehicle. The energy in fuel is required to overcome various losses encountered while propelling the vehicle, and in providing power to vehicle systems such as ignition or air conditioning. Various strategies can be employed to reduce losses at each of the conversions between the chemical energy in the fuel and the kinetic energy of the vehicle. Driver behavior can affect fuel economy; maneuvers such as sudden acceleration and heavy braking waste energy.

Mild hybrids (MHEV) are generally cars with an internal combustion engine (ICE) equipped with a negligibly bigger electric combined motor and generator in a parallel hybrid configuration allowing the engine to be turned off whenever the car is coasting, braking, or stopped, and then quickly restarted once power is again required. Mild hybrids may employ regenerative braking and some level of power assist to the internal combustion engine, but mild hybrids do not have an electric-only mode of propulsion.

Hybrid vehicle drivetrains transmit power to the driving wheels for hybrid vehicles. A hybrid vehicle has multiple forms of motive power.

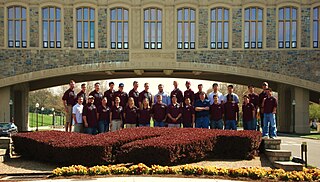

The Hokie Electric Vehicle Team of Virginia Tech, better known as HEVT, is a nationally recognized undergraduate student design team in the Department of Mechanical Engineering at Virginia Tech. HEVT was formed in 1994 to compete in the 1995 Hybrid Electric Vehicle (HEV) Challenge, one of the many competitions organized by the Argonne National Laboratory through the United States Department of Energy. HEVT has been involved in the Department of Energy Advanced Vehicle Technology Competitions (AVTCs) ever since. HEVT attributes a significant amount of its success to their Advisor, Professor Doug Nelson in Mechanical Engineering. Dr. Nelson has received the Outstanding Faculty Advisor award at competition 3 times. He has greatly aided the education of students at Virginia Tech and helped the team succeed at competition The overall highlights of past competitions are as follows:

A hybrid electric vehicle (HEV) is a type of hybrid vehicle that combines a conventional internal combustion engine (ICE) system with an electric propulsion system. The presence of the electric powertrain is intended to achieve either better fuel economy than a conventional vehicle or better performance. There is a variety of HEV types and the degree to which each function as an electric vehicle (EV) also varies. The most common form of HEV is the hybrid electric car, although hybrid electric trucks, buses, boats and aircraft also exist.

Energy-efficient driving techniques are used by drivers who wish to reduce their fuel consumption, and thus maximize fuel efficiency. Many drivers have the potential to improve their fuel efficiency significantly. Simple things such as keeping tires properly inflated, having a vehicle well-maintained and avoiding idling can dramatically improve fuel efficiency. Careful use of acceleration and deceleration and especially limiting use of high speeds helps efficiency. The use of multiple such techniques is called "hypermiling".

The seventh-generation Honda Civic is an automobile produced by Honda from 2000 until 2005. It debuted in September 2000 as a 2001 model. Its exterior dimensions stayed similar to the outgoing predecessor, with interior space significantly increased, bumping it up to the compact car size designation. A notable feature was the flat rear floor that gave better comfort to the rear seat passengers. This generation abandoned the front double wishbone suspension, used previously from fourth to sixth generations, replacing it with MacPherson struts. This generation was the last to offer 4WD variants.

Honda Advanced Technology is part of Honda's long-standing research and development program focused on building new models for their automotive products and automotive-related technologies, with many of the advances pertaining to engine technology. Honda's research has led to practical solutions ranging from fuel-efficient vehicles and engines, to more sophisticated applications such as the humanoid robot, ASIMO, and the Honda HA-420 Honda-jet, a six-passenger business jet.

Hydraulic hybrid vehicles (HHVs) use a pressurized fluid power source, along with a conventional internal combustion engine (ICE), to achieve better fuel economy and reductions in harmful emissions. They capture and reuse 70–80% of the vehicle's kinetic braking/decelerating energy and potential descending energy compared to 55% for electric hybrids. For trucks and buses, this can also be less expensive than electric systems, due to the price of batteries required for the latter. Hydraulic hybrid vehicle systems can also weigh less than electric systems, due to the high weight of the batteries. This can lead to a lower impact on payload capacity, especially for heavy vehicle classes.

References

- ↑ "Hydraulic Launch Assist (HLA)", Eaton Corporation , archived from the original on 12 May 2008, retrieved 12 August 2019

- ↑ Wiebusch (June 17, 2002), "Hydraulic regenerative braking improves large-truck fuel economy", Design News , archived from the original on September 30, 2007

- ↑ Mike Hanlon (4 June 2004). "Ford Tonka Truck". New Atlas.

- ↑ Siuru (April 2007), "Off to a quick start: Eaton's Corp.'s Hydraulic launch assist system demonstrated in shuttle bus, delivery van applications", Diesel Progress North American Edition

- ↑ Eaton Corporation (January 3, 2007), "Eaton's Greenhouse Gas Emission-Reducing Technologies To Benefit Texas Companies In 2007 Through State Grant For Environmentally Friendly Trucks", Press Release

- ↑ Peterbilt Motors (March 21, 2007), "PETERBILT'S HYBRID STRATEGY UTILIZES ADVANCED TECHNOLOGIES IN DEVELOPING FULL RANGE OF PRODUCT SOLUTIONS", Press Release, archived from the original on November 18, 2007

- ↑ Bohlman, Davis (December 13, 2007), "HYDRAULIC HYBRIDS ARE PICKING UP", Machine Design