Related Research Articles

Electrochemistry is the branch of physical chemistry concerned with the relationship between electrical potential difference and identifiable chemical change. These reactions involve electrons moving via an electronically conducting phase between electrodes separated by an ionically conducting and electronically insulating electrolyte.

An electrochemical cell is a device that generates electrical energy from chemical reactions. Electrical energy can also be applied to these cells to cause chemical reactions to occur. Electrochemical cells that generate an electric current are called voltaic or galvanic cells and those that generate chemical reactions, via electrolysis for example, are called electrolytic cells.

The voltaic pile was the first electrical battery that could continuously provide an electric current to a circuit. It was invented by Italian chemist Alessandro Volta, who published his experiments in 1799. Its invention can be traced back to an argument between Volta and Luigi Galvani, Volta's fellow Italian scientist who had conducted experiments on frogs' legs. Use of the voltaic pile enabled a rapid series of other discoveries, including the electrical decomposition (electrolysis) of water into oxygen and hydrogen by William Nicholson and Anthony Carlisle (1800), and the discovery or isolation of the chemical elements sodium (1807), potassium (1807), calcium (1808), boron (1808), barium (1808), strontium (1808), and magnesium (1808) by Humphry Davy.

In chemistry and manufacturing, electrolysis is a technique that uses direct electric current (DC) to drive an otherwise non-spontaneous chemical reaction. Electrolysis is commercially important as a stage in the separation of elements from naturally occurring sources such as ores using an electrolytic cell. The voltage that is needed for electrolysis to occur is called the decomposition potential. The word "lysis" means to separate or break, so in terms, electrolysis would mean "breakdown via electricity."

An electrolyte is a substance that conducts electricity through the movement of ions, but not through the movement of electrons. This includes most soluble salts, acids, and bases, dissolved in a polar solvent like water. Upon dissolving, the substance separates into cations and anions, which disperse uniformly throughout the solvent. Solid-state electrolytes also exist. In medicine and sometimes in chemistry, the term electrolyte refers to the substance that is dissolved.

Sodium chloride, commonly known as edible salt, is an ionic compound with the chemical formula NaCl, representing a 1:1 ratio of sodium and chlorine ions. It is transparent or translucent, brittle, hygroscopic, and occurs as the mineral halite. In its edible form, it is commonly used as a condiment and food preservative. Large quantities of sodium chloride are used in many industrial processes, and it is a major source of sodium and chlorine compounds used as feedstocks for further chemical syntheses. Another major application of sodium chloride is deicing of roadways in sub-freezing weather.

The Hall–Héroult process is the major industrial process for smelting aluminium. It involves dissolving aluminium oxide (alumina) in molten cryolite and electrolyzing the molten salt bath, typically in a purpose-built cell. The Hall–Héroult process applied at industrial scale happens at 940–980 °C and produces 99.5–99.8% pure aluminium. Recycling aluminum requires no electrolysis, thus it is not treated in this way.

In chemistry, the common-ion effect refers to the decrease in solubility of an ionic precipitate by the addition to the solution of a soluble compound with an ion in common with the precipitate. This behaviour is a consequence of Le Chatelier's principle for the equilibrium reaction of the ionic association/dissociation. The effect is commonly seen as an effect on the solubility of salts and other weak electrolytes. Adding an additional amount of one of the ions of the salt generally leads to increased precipitation of the salt, which reduces the concentration of both ions of the salt until the solubility equilibrium is reached. The effect is based on the fact that both the original salt and the other added chemical have one ion in common with each other.

An electrolytic cell is an electrochemical cell that utilizes an external source of electrical energy to force a chemical reaction that would otherwise not occur. The external energy source is a voltage applied between the cell's two electrodes; an anode and a cathode, which are immersed in an electrolyte solution. This is in contrast to a galvanic cell, which itself is a source of electrical energy and the foundation of a battery. The net reaction taking place in a galvanic cell is a spontaneous reaction, i.e., the Gibbs free energy remains -ve, while the net reaction taking place in an electrolytic cell is the reverse of this spontaneous reaction, i.e., the Gibbs free energy is +ve.

Industrial processes are procedures involving chemical, physical, electrical, or mechanical steps to aid in the manufacturing of an item or items, usually carried out on a very large scale. Industrial processes are the key components of heavy industry.

Molten-salt batteries are a class of battery that uses molten salts as an electrolyte and offers both a high energy density and a high power density. Traditional non-rechargeable thermal batteries can be stored in their solid state at room temperature for long periods of time before being activated by heating. Rechargeable liquid-metal batteries are used for industrial power backup, special electric vehiclesand for grid energy storage, to balance out intermittent renewable power sources such as solar panels and wind turbines.

Beta-alumina solid electrolyte (BASE) is a fast-ion conductor material used as a membrane in several types of molten salt electrochemical cell. Currently there is no known substitute available. β-Alumina exhibits an unusual layered crystal structure which enables very fast-ion transport. β-Alumina is not an isomorphic form of aluminium oxide (Al2O3), but a sodium polyaluminate. It is a hard polycrystalline ceramic, which, when prepared as an electrolyte, is complexed with a mobile ion, such as Na+, K+, Li+, Ag+, H+, Pb2+, Sr2+ or Ba2+ depending on the application. β-Alumina is a good conductor of its mobile ion yet allows no non-ionic (i.e., electronic) conductivity. The crystal structure of the β-alumina provides an essential rigid framework with channels along which the ionic species of the solid can migrate. Ion transport involves hopping from site to site along these channels. Since the 1970s this technology has been thoroughly developed, resulting in interesting applications. Its special characteristics on ion and electrical conductivity make this material extremely interesting in the field of energy storage.

Downs' process is an electrochemical method for the commercial preparation of metallic sodium, in which molten NaCl is electrolyzed in a special apparatus called the Downs cell. The Downs cell was invented in 1923 by the American chemist James Cloyd Downs (1885–1957).

Aluminium smelting is the process of extracting aluminium from its oxide, alumina, generally by the Hall-Héroult process. Alumina is extracted from the ore bauxite by means of the Bayer process at an alumina refinery.

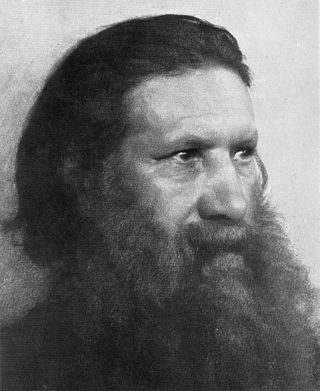

James Hargreaves was a British chemist and an inventor. He was born at Hoarstones in Fence, Lancashire, the eldest child of James Hargreaves, a schoolmaster at Slaithwaite near Marsden. His father moved to Sabden but as he found his salary to be insufficient the father became a druggist in 1844, later moving to Preston.

An electric vehicle battery is a rechargeable battery used to power the electric motors of a battery electric vehicle (BEV) or hybrid electric vehicle (HEV).

Chlorine gas can be produced by extracting from natural materials, including the electrolysis of a sodium chloride solution (brine) and other ways.

An electric battery is a source of electric power consisting of one or more electrochemical cells with external connections for powering electrical devices. When a battery is supplying power, its positive terminal is the cathode and its negative terminal is the anode. The terminal marked negative is the source of electrons. When a battery is connected to an external electric load, those negatively charged electrons flow through the circuit and reach to the positive terminal, thus cause a redox reaction by attracting positively charged ions, cations. Thus converts high-energy reactants to lower-energy products, and the free-energy difference is delivered to the external circuit as electrical energy. Historically the term "battery" specifically referred to a device composed of multiple cells; however, the usage has evolved to include devices composed of a single cell.

Electrochemical grinding is a process that removes electrically conductive material by grinding with a negatively charged abrasive grinding wheel, an electrolyte fluid, and a positively charged workpiece. Materials removed from the workpiece stay in the electrolyte fluid. Electrochemical grinding is similar to electrochemical machining but uses a wheel instead of a tool shaped like the contour of the workpiece.

Electrochemical engineering is the branch of chemical engineering dealing with the technological applications of electrochemical phenomena, such as electrosynthesis of chemicals, electrowinning and refining of metals, flow batteries and fuel cells, surface modification by electrodeposition, electrochemical separations and corrosion.

References

- 1 2 "J. Cloyd Downs". www.ancestry.com. Retrieved November 4, 2024.

- ↑ "Historic Saranac Lake - J. Cloyd Downs" . Retrieved 3 November 2024.

- 1 2 "Obituaries". Oil, Paint and Drug Reporter. 172: 51. December 21, 1957. Retrieved 3 November 2024.

- ↑ Hardie, D W F (1959). Electrolytic manufacture of chemicals from salt. London: Oxford University Press. p. 2.

Practically all sodium cells are now of the Downs type.

- ↑ Gale Encyclopedia Of Science. Vol. 7 (5 ed.). 2014. p. 4014.

- 1 2 3 "Wins Chemistry Prize James Cloyd Downs". New York Times. New York. May 27, 1934. Retrieved November 5, 2024.

- ↑ "Ray Downs Obituary". www.legacy.com. Atlanta Journal-Constitution. December 15, 2006. Retrieved November 4, 2024.

- ↑ "Inventor Succumbs". Stroudsburg Daily Record. December 19, 1957. Retrieved November 4, 2024.

- ↑ USExpired - Lifetime 1,501,756,James Cloyd Downs,"Electrolytic process and cell",published 1924