A hybrid-propellant rocket is a rocket with a rocket motor that uses rocket propellants in two different phases: one solid and the other either gas or liquid. The hybrid rocket concept can be traced back to the early 1930s.

A hypergolic propellant is a rocket propellant combination used in a rocket engine, whose components spontaneously ignite when they come into contact with each other.

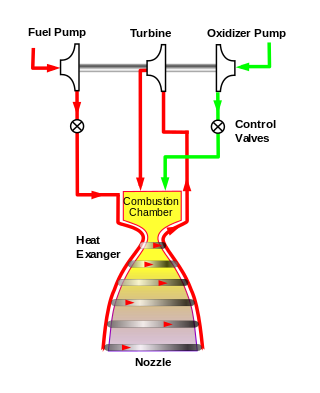

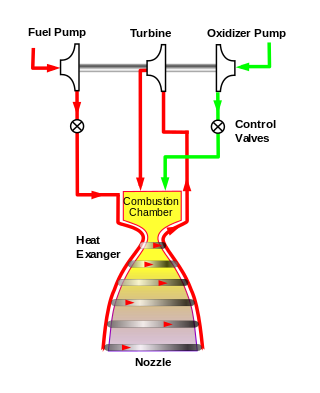

The expander cycle is a power cycle of a bipropellant rocket engine. In this cycle, the fuel is used to cool the engine's combustion chamber, picking up heat and changing phase. The now heated and gaseous fuel then powers the turbine that drives the engine's fuel and oxidizer pumps before being injected into the combustion chamber and burned.

A liquid-propellant rocket or liquid rocket utilizes a rocket engine burning liquid propellants. (Alternate approaches use gaseous or solid propellants.) Liquids are desirable propellants because they have reasonably high density and their combustion products have high specific impulse (Isp). This allows the volume of the propellant tanks to be relatively low.

The Aerojet Rocketdyne RS-25, also known as the Space Shuttle Main Engine (SSME), is a liquid-fuel cryogenic rocket engine that was used on NASA's Space Shuttle and is currently used on the Space Launch System (SLS).

The J-2, commonly known as Rocketdyne J-2, was a liquid-fuel cryogenic rocket engine used on NASA's Saturn IB and Saturn V launch vehicles. Built in the United States by Rocketdyne, the J-2 burned cryogenic liquid hydrogen (LH2) and liquid oxygen (LOX) propellants, with each engine producing 1,033.1 kN (232,250 lbf) of thrust in vacuum. The engine's preliminary design dates back to recommendations of the 1959 Silverstein Committee. Rocketdyne won approval to develop the J-2 in June 1960 and the first flight, AS-201, occurred on 26 February 1966. The J-2 underwent several minor upgrades over its operational history to improve the engine's performance, with two major upgrade programs, the de Laval nozzle-type J-2S and aerospike-type J-2T, which were cancelled after the conclusion of the Apollo program.

The LE-7 and its succeeding upgrade model the LE-7A are staged combustion cycle LH2/LOX liquid rocket engines produced in Japan for the H-II series of launch vehicles. Design and production work was all done domestically in Japan, the first major (main/first-stage) liquid rocket engine with that claim, in a collaborative effort from the National Space Development Agency (NASDA), Aerospace Engineering Laboratory (NAL), Mitsubishi Heavy Industries, and Ishikawajima-Harima. NASDA and NAL have since been integrated into JAXA. However, a large part of the work was contracted to Mitsubishi, with Ishikawajima-Harima providing turbomachinery, and the engine is often referred to as the Mitsubishi LE-7(A).

The Titan II GLV or Gemini-Titan II was an American expendable launch system derived from the Titan II missile, which was used to launch twelve Gemini missions for NASA between 1964 and 1966. Two uncrewed launches followed by ten crewed ones were conducted from Launch Complex 19 at the Cape Canaveral Air Force Station, starting with Gemini 1 on April 8, 1964.

A cryogenic rocket engine is a rocket engine that uses a cryogenic fuel and oxidizer; that is, both its fuel and oxidizer are gases which have been liquefied and are stored at very low temperatures. These highly efficient engines were first flown on the US Atlas-Centaur and were one of the main factors of NASA's success in reaching the Moon by the Saturn V rocket.

The LR87 was an American liquid-propellant rocket engine used on the first stages of Titan intercontinental ballistic missiles and launch vehicles. Composed of twin motors with separate combustion chambers and turbopump machinery, it is considered a single unit and was never flown as a single combustion chamber engine or designed for this. The LR87 first flew in 1959.

Copenhagen Suborbitals is a crowd-funded human space program. It has flown six home-built rockets and capsules since 2011. The organization successfully launched its Nexø II rocket in the summer of 2018. Its stated goal is to have one of its members reach space on a sub-orbital spaceflight. The organization was founded by Kristian von Bengtson and Peter Madsen.

Nitrous oxide fuel blend propellants are a class of liquid rocket propellants that were intended in the early 2010s to be able to replace hydrazine as the standard storable rocket propellent in some applications.

Rocket propellant is the reaction mass of a rocket. This reaction mass is ejected at the highest achievable velocity from a rocket engine to produce thrust. The energy required can either come from the propellants themselves, as with a chemical rocket, or from an external source, as with ion engines.

TM65 is a rocket engine developed by Copenhagen Suborbitals. TM65 uses Ethanol and liquid oxygen as propellants in a pressure-fed power cycle.

The TR-201 or TR201 is a hypergolic pressure-fed rocket engine used to propel the upper stage of the Delta rocket, referred to as Delta-P, from 1972 to 1988. The rocket engine uses Aerozine 50 as fuel, and N

2O

4 as oxidizer. It was developed in the early 1970s by TRW as a derivative of the lunar module descent engine (LMDE). This engine used a pintle injector first invented by Gerard W. Elverum Jr. and developed by TRW in the late 1950s and received US Patent in 1972. This injector technology and design is also used on SpaceX Merlin engines.

Since the founding of SpaceX in 2002, the company has developed four families of rocket engines — Merlin, Kestrel, Draco and SuperDraco — and is currently developing another rocket engine: Raptor, and after 2020, a new line of methalox thrusters.

The BE-3 is a LH2/LOX rocket engine developed by Blue Origin.

Raptor is a family of rocket engines developed and manufactured by SpaceX. The engine is a full-flow staged combustion cycle (FFSC) engine powered by cryogenic liquid methane and liquid oxygen ("methalox").

TEPREL is a family of rocket engines designed and built by the Spanish aerospace company PLD Space for their Miura 1 and Miura 5 launch vehicles. The TEPREL engine, named after the Spanish reusable engine program that is financing its development, uses kerosene and liquid oxygen as propellants. So far, several versions of this engine, intended to propel Miura 1, have been developed and tested on the company's own liquid propulsion test facilities located in Teruel, Spain.

BluShift Aerospace is an employee-owned American aerospace firm based in Brunswick, Maine. Targeting the growing smallsat and cubesat launch markets, bluShift is developing suborbital sounding rockets and small-lift orbital rockets which will be launched from a proposed new spaceport in Maine. The company has received primary funding from NASAs SBIR grant program, the National Science Foundations I-Corps grant program, the Maine Technology Institute, and the Maine Space Grant Consortium. The company has active operations at the former Brunswick Naval Air Station and Loring Air Force Base.