Pottery is the process and the products of forming vessels and other objects with clay and other raw materials, which are fired at high temperatures to give them a hard and durable form. The place where such wares are made by a potter is also called a pottery. The definition of pottery, used by the ASTM International, is "all fired ceramic wares that contain clay when formed, except technical, structural, and refractory products". End applications include tableware, decorative ware, sanitary ware, and in technology and industry such as electrical insulators and laboratory ware. In art history and archaeology, especially of ancient and prehistoric periods, pottery often means only vessels, and sculpted figurines of the same material are called terracottas.

Earthenware is glazed or unglazed nonvitreous pottery that has normally been fired below 1,200 °C (2,190 °F). Basic earthenware, often called terracotta, absorbs liquids such as water. However, earthenware can be made impervious to liquids by coating it with a ceramic glaze, and such a process is used for the great majority of modern domestic earthenware. The main other important types of pottery are porcelain, bone china, and stoneware, all fired at high enough temperatures to vitrify. End applications include tableware and decorative ware such as figurines.

Pottery and porcelain is one of the oldest Japanese crafts and art forms, dating back to the Neolithic period. Types have included earthenware, pottery, stoneware, porcelain, and blue-and-white ware. Japan has an exceptionally long and successful history of ceramic production. Earthenwares were made as early as the Jōmon period, giving Japan one of the oldest ceramic traditions in the world. Japan is further distinguished by the unusual esteem that ceramics hold within its artistic tradition, owing to the enduring popularity of the tea ceremony. During the Azuchi-Momoyama period (1573-1603), kilns throughout Japan produced ceramics with unconventional designs. In the early Edo period, the production of porcelain commenced in the Hizen-Arita region of Kyushu, employing techniques imported from Korea. These porcelain works became known as Imari wares, named after the port of Imari from which they were exported to various markets, including Europe.

Salt-glaze or salt glaze pottery is pottery, usually stoneware, with a ceramic glaze of glossy, translucent and slightly orange-peel-like texture which was formed by throwing common salt into the kiln during the higher temperature part of the firing process. Sodium from the salt reacts with silica in the clay body to form a glassy coating of sodium silicate. The glaze may be colourless or may be coloured various shades of brown, blue, or purple.

Creamware is a cream-coloured refined earthenware with a lead glaze over a pale body, known in France as faïence fine, in the Netherlands as Engels porselein, and in Italy as terraglia inglese. It was created about 1750 by the potters of Staffordshire, England, who refined the materials and techniques of salt-glazed earthenware towards a finer, thinner, whiter body with a brilliant glassy lead glaze, which proved so ideal for domestic ware that it supplanted white salt-glaze wares by about 1780. It was popular until the 1840s.

Korean ceramic history begins with the oldest earthenware from around 8000 BC. Throughout the history, the Korean peninsula has been home to lively, innovative, and sophisticated art making. Long periods of stability have allowed for the establishment of spiritual traditions, and artisan technologies specific to the region. Korean ceramics in Neolithic period have a unique geometric patterns of sunshine, or it is decorated with twists. In Southern part of Korea, Mumun pottery were popular. Mumun togi used specific minerals to make colors of red and black. Korean pottery developed a distinct style of its own, with its own shapes, such as the moon jar or Buncheong sagi which is a new form between earthenware and porcelain, white clay inlay celadon of Goryeo, and later styles like minimalism that represents Korean Joseon philosophers' idea. Many talented Korean potters were captured and brought to Japan during the invasions of Korea, where they heavily contributed to advancing Japanese pottery. Arita ware, founded by Yi Sam-pyeong opened a new era of porcelain in Japan. Another Japanese representative porcelain, Satsuma ware was also founded by Dang-gil Shim and Pyeong-ui Park. 14th generation of Su-kwan Shim have been using the same name to his grandfather and father to honor they are originally Korean, 14th Su-kwan Shim is honorable citizen of Namwon, Korea.

Langley Mill Pottery was located in Langley Mill, Derbyshire on the Derbyshire – Nottinghamshire border. From its establishment in 1865 to its final closure in 1982, the pottery went through five distinct periods of ownership, producing a wide range of stoneware ranging from salt glazed ink bottles, utilitarian items and tableware to high quality and original art pottery.

Studio pottery is pottery made by professional and amateur artists or artisans working alone or in small groups, making unique items or short runs. Typically, all stages of manufacture are carried out by the artists themselves. Studio pottery includes functional wares such as tableware and cookware, and non-functional wares such as sculpture, with vases and bowls covering the middle ground, often being used only for display. Studio potters can be referred to as ceramic artists, ceramists, ceramicists or as an artist who uses clay as a medium.

Royal Doulton is an English ceramic and home accessories manufacturer that was founded in 1815. Operating originally in Vauxhall, London, and later moving to Lambeth, in 1882 it opened a factory in Burslem, Stoke-on-Trent, in the centre of English pottery. From the start, the backbone of the business was a wide range of utilitarian wares, mostly stonewares, including storage jars, tankards and the like, and later extending to drain pipes, lavatories, water filters, electrical porcelain and other technical ceramics. From 1853 to 1901, its wares were marked Doulton & Co., then from 1901, when a royal warrant was given, Royal Doulton.

Chinese ceramics are one of the most significant forms of Chinese art and ceramics globally. They range from construction materials such as bricks and tiles, to hand-built pottery vessels fired in bonfires or kilns, to the sophisticated Chinese porcelain wares made for the imperial court and for export.

Michael Ambrose Cardew (1901–1983), was an English studio potter who worked in West Africa for twenty years.

Dorchester Pottery Works is a historic site at 101-105 Victory Road in Dorchester, Massachusetts, a neighborhood of Boston. The Dorchester Pottery Works was founded in 1895 by George Henderson and made stoneware. The Dorchester Pottery Works closed in 1979. The building was designated as a Boston Landmark in 1980 and added to the National Register of Historic Places in 1985.

Crown Lynn was a New Zealand ceramics manufacturer that operated under various names between 1854 and 1989.

Red Wing pottery refers to American stoneware, pottery, or dinnerware items made by a company initially set up in Red Wing, Minnesota, in 1861 by German immigrant John Paul, which changed its names several times until finally settling on Red Wing Potteries, Inc. in 1936. The pottery factory that started in 1861 continues to the present day under the names of Red Wing Pottery and Red Wing Stoneware. There was a respite in production when Red Wing Pottery Sales, Inc. had a strike in 1967 causing them to temporarily cease trading. The company still makes both zinc/Bristol glazed products as well as salt-glazed, hand-thrown, kiln fired items.

Art pottery is a term for pottery with artistic aspirations, made in relatively small quantities, mostly between about 1870 and 1930. Typically, sets of the usual tableware items are excluded from the term; instead the objects produced are mostly decorative vessels such as vases, jugs, bowls and the like which are sold singly. The term originated in the later 19th century, and is usually used only for pottery produced from that period onwards. It tends to be used for ceramics produced in factory conditions, but in relatively small quantities, using skilled workers, with at the least close supervision by a designer or some sort of artistic director. Studio pottery is a step up, supposed to be produced in even smaller quantities, with the hands-on participation of an artist-potter, who often performs all or most of the production stages. But the use of both terms can be elastic. Ceramic art is often a much wider term, covering all pottery that comes within the scope of art history, but "ceramic artist" is often used for hands-on artist potters in studio pottery.

Ray Finch MBE, formally Alfred Raymond Finch, was an English studio potter who worked at Winchcombe Pottery for a period spanning seventy-five years.

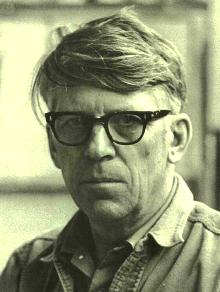

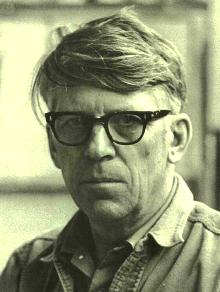

Luke Orton Lindoe was a Canadian potter, painter, sculptor, and businessman who did most of his work in Alberta, Canada. For long periods he was based in Medicine Hat. He had many different jobs, from mineral prospecting, coal mining, and teaching art, to producing potting clay and manufacturing ceramic products such as ashtrays. He also had many commissions for stone or concrete murals on public buildings. During his lifetime he gained a high reputation as a mentor of ceramic artists and for his own ceramics, oil paintings, and sculptures.

Ceramic art is art made from ceramic materials, including clay. It may take varied forms, including artistic pottery, including tableware, tiles, figurines and other sculpture. As one of the plastic arts, ceramic art is a visual art. While some ceramics are considered fine art, such as pottery or sculpture, most are considered to be decorative, industrial or applied art objects. Ceramic art can be created by one person or by a group, in a pottery or a ceramic factory with a group designing and manufacturing the artware.

The Bonaparte Pottery Archeological District is a nationally recognized historic district located in Bonaparte, Iowa, United States. It was listed on the National Register of Historic Places in 1999. At the time of its nomination it contained four resources, which included one contributing building, one contributing site, and two non-contributing buildings. The contributing resources include the remains of two kilns from Bonaparte Pottery, which operated from 1866 to 1895. It also includes the factory building (1876) that replaced a building that was destroyed in a fire in November 1875. The non-contributing resources include two buildings that are associated with the lumberyard that took over the site after the pottery closed. They were built after the period of historical significance.

Denise Wren was an Australian-born British studio potter and craftsperson. Wren was one of the first female studio potters in Britain. She studied and taught with the Kingston School of Art, Knox Guild and Camberwell College of Arts. Wren and her family subsequently set up the Oxshott Pottery and wrote on the subjects of ceramics, textiles and making.