A power station, also referred to as a power plant and sometimes generating station or generating plant, is an industrial facility for the generation of electric power. Power stations are generally connected to an electrical grid.

A combined cycle power plant is an assembly of heat engines that work in tandem from the same source of heat, converting it into mechanical energy. On land, when used to make electricity the most common type is called a combined cycle gas turbine (CCGT) plant. The same principle is also used for marine propulsion, where it is called a combined gas and steam (COGAS) plant. Combining two or more thermodynamic cycles improves overall efficiency, which reduces fuel costs.

A thermal power station is a type of power station in which heat energy is converted to electrical energy. In a steam-generating cycle heat is used to boil water in a large pressure vessel to produce high-pressure steam, which drives a steam turbine connected to an electrical generator. The low-pressure exhaust from the turbine enters a steam condenser where it is cooled to produce hot condensate which is recycled to the heating process to generate more high pressure steam. This is known as a Rankine cycle.

Teesside Power Station is a former gas-fired power station, in Redcar & Cleveland, England. Situated near the Wilton chemical complex, the station had combined cycle gas turbines (CCGTs) and open cycle gas turbines (OCGTs), however in 2011 the operation of the CCGT part of the station was suspended, and in 2013 the owners announced its closure and plans to demolish it. Prior to the suspension, the station had a generating capacity of 1875 megawatts (MW), making it the largest of any CCGT power station in Europe. The station could meet almost 3% of the electricity demand for England, Wales and Scotland. Opened in 1993, the station was initially operated by Enron but moved into the hands of PX Ltd after the Enron scandal of 2001, before being bought by Gaz de France and Suez in 2008. The station also worked as a cogeneration plant, providing steam for the Wilton complex.

Peterhead Power Station is a multi-unit station owned and operated by SSE plc, with a capacity of 2,177 MW. It is located near Boddam and the A90, just south of Peterhead, in Aberdeenshire, in the northeast of Scotland. It stands next to Sandford Lodge, a circa-1800-built structure. Initially operating as an oil-fired power station and later transitioning to fossil gas, the plant has also served as a site for experimental hydrogen generation capacity.

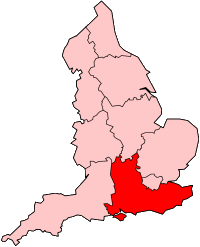

Damhead Creek power station is a 792 MWe gas-fired power station in Kent, England, on the Hoo Peninsula, It is near the site of the decommissioned Kingsnorth power station. The plant entered service in February 2001.

Grain Power Station is a 1,275 megawatts (1,710,000 hp) operational CCGT power station in Kent, England, owned by Uniper. It was also the name of an oil-fired, now demolished, 1,320MW power station in operation from 1979 to 2012.

Coolkeeragh power station is a power station near Derry in Northern Ireland.

Spalding Power Station is a 860 MW gas-fired power station one mile north of Spalding on West Marsh Road close to the River Welland. The current site provides enough electricity for one million households.

Glanford Brigg Power Station is a gas-fired power station in North Lincolnshire, England. It is capable of firing diesel as a substitute of natural gas. It is situated on the River Ancholme, beside the Sheffield to Cleethorpes via Brigg Line, outside the town of Brigg, with its name coming from the former name for the town. It has a generating capacity of 240 megawatts (MW).

Keadby Power Stations are a pair of natural gas-fired power stations near Scunthorpe in North Lincolnshire, built on the site of an older coal power station. The site lies near the B1392 and the River Trent, and the Scunthorpe-Grimsby railway. Also nearby is the Stainforth and Keadby Canal, which is part of the Sheffield and South Yorkshire Navigation. The current stations are operated by SSE Thermal.

Seabank Power Station is a 1,140 MW gas-fired power station at Hallen Marsh in Bristol, England. It is situated beside the A403 road and Severn Estuary, just north of Avonmouth and south of Severn Beach, close to the boundary with South Gloucestershire. It is next to the former Terra Nitrogen Severnside fertiliser works, which was closed by Growhow UK in January 2008.

Coryton Power Station is a 732 MW Combined Cycle Gas Turbine (CCGT) gas-fired power station at Coryton, Thurrock, Essex, UK.

Roosecote Power Station was a gas-fired, originally coal-fired power station, situated in the Roosecote district of Barrow-in-Furness in Cumbria, North West England. The gas-fired station opened in 1991 and was the first CCGT power station to supply electricity to the United Kingdom's National Grid, but was mothballed in 2012 after a proposed biomass power station was cancelled. It was situated directly adjacent to Rampside Gas Terminal. The plant was demolished between 2014 and 2015. The site is now a 49 MW battery storage facility.

Shoreham Power Station is a 420MWe combined cycle gas-fired power station in Southwick, West Sussex. It was built on the site of the Brighton B Power Station.

Shotton Combined Heat and Power Station was a 210 MWe gas-fired CHP power station in Flintshire, Wales. It was located on Weighbridge Road in Deeside, near the A548 in Shotton, Flintshire.

Barry Power Station was a 230 MWe gas-fired power station on Sully Moors Road in Sully in the Vale of Glamorgan, Wales. It was eight miles west of Cardiff and was situated next to a large Ineos Vinyls chemicals works that makes PVC and a Hexion Chemicals plant.

Carrington Power Station is a combined cycle gas turbine power station, which was completed in Autumn 2016 and began commercial operation on 18 September 2016. It is located on the site of a former coal-fired power station, close to the villages of Carrington and Partington in the Greater Manchester Area and 12 km (7.5 mi) southwest of Manchester City Centre. The Manchester Ship Canal and the River Mersey run alongside the site, in Trafford, Greater Manchester, in North West England.

Nooter Eriksen, also known as Nooter/Eriksen or N/E, is a supplier of heat recovery steam generators, which are mostly found in combined cycle gas turbine power stations (CCGTs). These are also found in combined heat and power (CHP) systems, which tend to have a much smaller power output than CCGT stations. Nooter Eriksen is a subsidiary of CIC Group, also owning Nooter Construction, the Wyatt Group.

Whitegate power station is a 445 MW combined cycle gas turbine (CCGT) electricity generating station near Whitegate, County Cork in Ireland. It was commissioned in 2010 and can supply up to ten percent of the electricity demand in Ireland.