Polypropylene (PP), also known as polypropene, is a thermoplastic polymer used in a wide variety of applications. It is produced via chain-growth polymerization from the monomer propylene.

Wood–plastic composites (WPCs) are composite materials made of wood fiber/wood flour and thermoplastic(s) such as polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), or polylactic acid (PLA).

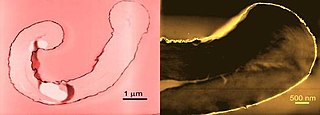

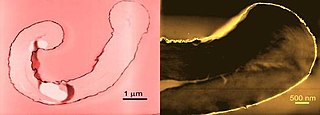

Electrospinning is a fiber production method that uses electrical force to draw charged threads of polymer solutions for producing nanofibers with diameters ranging from nanometers to micrometers. Electrospinning shares characteristics of both electrospraying and conventional solution dry spinning of fibers. The process does not require the use of coagulation chemistry or high temperatures to produce solid threads from solution. This makes the process particularly suited to the production of fibers using large and complex molecules. Electrospinning from molten precursors is also practiced; this method ensures that no solvent can be carried over into the final product.

Blow molding is a manufacturing process for forming hollow plastic parts. It is also used for forming glass bottles or other hollow shapes.

A sorbent is an insoluble material that either absorbs or adsorbs liquids or gases. They are frequently used to remove pollutants and in the cleanup of chemical accidents and oil spills. Besides their uses in industry, sorbents are used in commercial products such as diapers and odor absorbents, and are researched for applications in environmental air analysis, particularly in the analysis of volatile organic compounds. The name sorbent is derived from sorption, which is itself a derivation from adsorption and absorption.

Nonwoven fabric or non-woven fabric is a fabric-like material made from staple fibre (short) and long fibres, bonded together by chemical, mechanical, heat or solvent treatment. The term is used in the textile manufacturing industry to denote fabrics, such as felt, which are neither woven nor knitted. Some non-woven materials lack sufficient strength unless densified or reinforced by a backing. In recent years, non-wovens have become an alternative to polyurethane foam.

Nanofibers are fibers with diameters in the nanometer range. Nanofibers can be generated from different polymers and hence have different physical properties and application potentials. Examples of natural polymers include collagen, cellulose, silk fibroin, keratin, gelatin and polysaccharides such as chitosan and alginate. Examples of synthetic polymers include poly(lactic acid) (PLA), polycaprolactone (PCL), polyurethane (PU), poly(lactic-co-glycolic acid) (PLGA), poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV), and poly(ethylene-co-vinylacetate) (PEVA). Polymer chains are connected via covalent bonds. The diameters of nanofibers depend on the type of polymer used and the method of production. All polymer nanofibers are unique for their large surface area-to-volume ratio, high porosity, appreciable mechanical strength, and flexibility in functionalization compared to their microfiber counterparts.

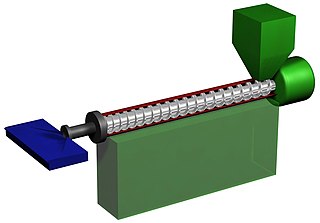

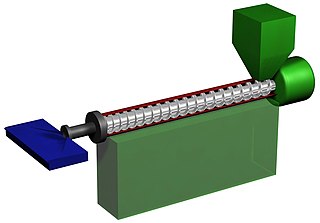

Plastics extrusion is a high-volume manufacturing process in which raw plastic is melted and formed into a continuous profile. Extrusion produces items such as pipe/tubing, weatherstripping, fencing, deck railings, window frames, plastic films and sheeting, thermoplastic coatings, and wire insulation.

Olefin fiber is a synthetic fiber made from a polyolefin, such as polypropylene or polyethylene. It is used in wallpaper, carpeting, ropes, and vehicle interiors.

Nanofabrics are textiles engineered with small particles that give ordinary materials advantageous properties such as superhydrophobicity, odor and moisture elimination, increased elasticity and strength, and bacterial resistance. Depending on the desired property, a nanofabric is either constructed from nanoscopic fibers called nanofibers, or is formed by applying a solution containing nanoparticles to a regular fabric. Nanofabrics research is an interdisciplinary effort involving bioengineering, molecular chemistry, physics, electrical engineering, computer science, and systems engineering. Applications of nanofabrics have the potential to revolutionize textile manufacturing and areas of medicine such as drug delivery and tissue engineering.

Biotextiles are specialized materials engineered from natural or synthetic fibers. These textiles are designed to interact with biological systems, offering properties such as biocompatibility, porosity, and mechanical strength or are designed to be environmentally friendly for typical household applications. There are several uses for biotextiles since they are a broad category. The most common uses are for medical or household use. However, this term may also refer to textiles constructed from biological waste product. These biotextiles are not typically used for industrial purposes.

Filler materials are particles added to resin or binders that can improve specific properties, make the product cheaper, or a mixture of both. The two largest segments for filler material use is elastomers and plastics. Worldwide, more than 53 million tons of fillers are used every year in application areas such as paper, plastics, rubber, paints, coatings, adhesives, and sealants. As such, fillers, produced by more than 700 companies, rank among the world's major raw materials and are contained in a variety of goods for daily consumer needs. The top filler materials used are ground calcium carbonate (GCC), precipitated calcium carbonate (PCC), kaolin, talc, and carbon black. Filler materials can affect the tensile strength, toughness, heat resistance, color, clarity, etc. A good example of this is the addition of talc to polypropylene. Most of the filler materials used in plastics are mineral or glass based filler materials. Particulates and fibers are the main subgroups of filler materials. Particulates are small particles of filler that are mixed in the matrix where size and aspect ratio are important. Fibers are small circular strands that can be very long and have very high aspect ratios.

Spinning is a manufacturing process for creating polymer fibers. It is a specialized form of extrusion that uses a spinneret to form multiple continuous filaments.

Melt electrospinning is a processing technique to produce fibrous structures from polymer melts for applications that include tissue engineering, textiles and filtration. In general, electrospinning can be performed using either polymer melts or polymer solutions. However, melt electrospinning is distinct in that the collection of the fiber can very focused; combined with moving collectors, melt electrospinning writing is a way to perform 3D printing. Since volatile solvents are not used, there are benefits for some applications where solvent toxicity and accumulation during manufacturing are a concern.

A die in polymer processing is a metal restrictor or channel capable of providing a constant cross sectional profile to a stream of liquid polymer. This allows for continuous processing of shapes such as sheets, films, pipes, rods, and other more complex profiles. This is a continuous process, allowing for constant production, as opposed to a sequential (non-constant) process such as injection molding.

Christopher Ward Macosko (1944) is an American chemical engineer and professor emeritus in the department of chemical engineering and materials science at the University of Minnesota. He is internationally known for his work in polymer science and engineering, especially in the areas of rheology and polymer processing. Macosko is an author of more than 500 academic papers, dozens of patents, and two books including the text: "Rheology: Principles, Measurements and Applications". He served as director of the Industrial Partnership for Research in Interfacial and Materials Engineering (IPRIME), a university-industry consortium at the University of Minnesota, from 1999 to 2018. Macosko and his wife Kathleen have been married since 1967 and are long-time residents of Minneapolis. They have four children and 12 grandchildren.

Extrusion welding is one of the processes used to weld thermoplastics and composites, developed in the 1960s as an evolution of hot gas welding. It can be a manual or automated process.

Bicomponent fiber is made of two materials, utilizing desired properties of each material.

Covema srl was a historic Italian company specializing in the design of plastic processing machinery, based in Milan, via Fontana 1. Founded in 1953 by the Terragni brothers, it also included the companies Corima spa, GBF spa, GBF iberica, RIAP srl, FIRS spa, Covepla Spain, Italproducts srl, Omam spa, TPA srl, AGRIPAK srl, Floraplant srl, Interfinance SA, Technical Die spa, Covema SAE. The technology that Covema has developed since the 1950s is merged into Agripak srl based in Milano and managed by the sons of Marco Terragni: Fabio Terragni (president), Patrizia Terragni and Massimo Terragni.

Medical textiles are numerous fiber-based materials intended for medical purposes. Medical textile is a sector of technical textiles that emphasizes fiber-based products used in health care applications such as prevention, care, and hygiene.